Subaru Legacy IV (2008 year). Service manual - part 14

PI-13

Pre-delivery Inspection

PRE-DELIVERY INSPECTION

22.ALARM SYSTEM

NOTE:

The following inspections show the initial settings.

When the settings are different from the initial set-

tings, use Subaru Select Monitor to check the de-

tails of each setting for inspections. <Ref. to

LAN(diag)-30, OPERATION, Function Setting

(Customize).>

1) Fully open all the door windows.

2) Remove the key from the ignition switch and

close all the doors including rear gate.

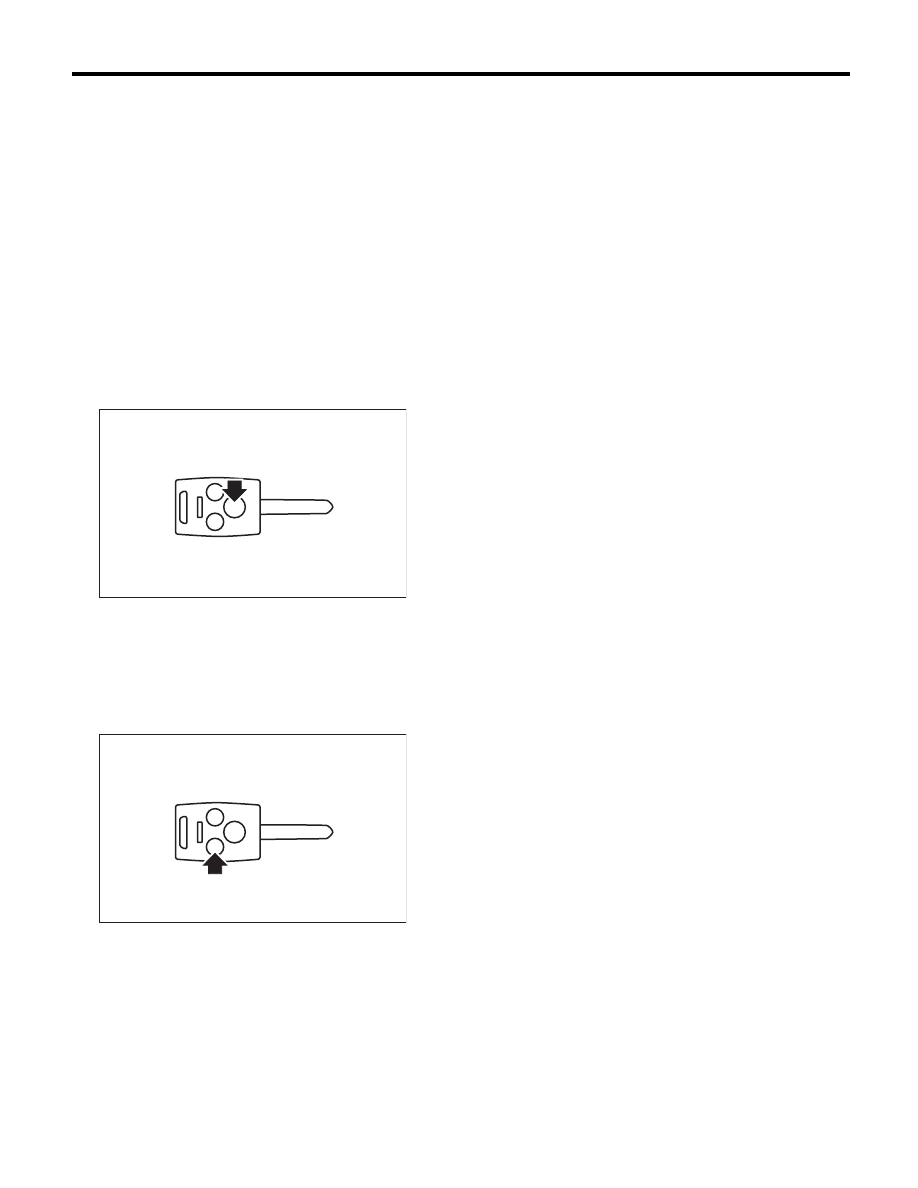

3) Press the “LOCK” button momentarily on the

keyless transmitter. All doors are locked, and buzz-

er sounds once, hazard blinks once, security indi-

cator light blinks faster (five times per two seconds)

for 30 seconds and goes slower (twice per two sec-

onds), then the alarm system is in set condition.

4) Press the “UNLOCK” button momentarily on the

keyless transmitter. When the door of the driver’s

seat is unlocked, the buzzer sounds twice, the haz-

ard light flashes twice, the room light turns on and

the security indicator light flashes once in three

seconds, and the alarm system enters the release

mode.

5) Close all the doors including rear gate. Press the

“LOCK” button momentarily on the keyless trans-

mitter. When all the doors are locked, buzzer

sounds once, hazard blinks once and the alarm

system is in set condition in 30 seconds.

6) Unlock a door using the inner lock knob and

open the door while the security system is in the set

mode. Check if the alarm condition happens (horn

sounds continuously, hazard light blinks, security

indicator illuminates). Check if this condition lasts

for a maximum of three minutes or until the “UN-

LOCK” button of the keyless transmitter is pressed.

NOTE:

The alarm condition will cease in 30 seconds once

the door is closed.

7) When none of above is applicable, check the

troubleshooting of security system.

PI-00387

PI-00388