Subaru Legacy (2005 year). Service manual - part 676

6MT-51

MANUAL TRANSMISSION AND DIFFERENTIAL

Extension Case

14) Calculate the value “t” of transfer driven gear

bearing thrust washer using the following equation.

t = Z

− (100 − Y) − {−0.04 to 0.11 mm (−0.0016 to

0.0043 in)}

15) Select the nearest thrust washer from the fol-

lowing table, according to the calculated value “t”.

Standard clearance between thrust washer and

taper roller bearing:

−

0.04 — 0.11 mm (

−

0.0016 — 0.0043 in)

NOTE:

Be sure that it is within standard clearance range.

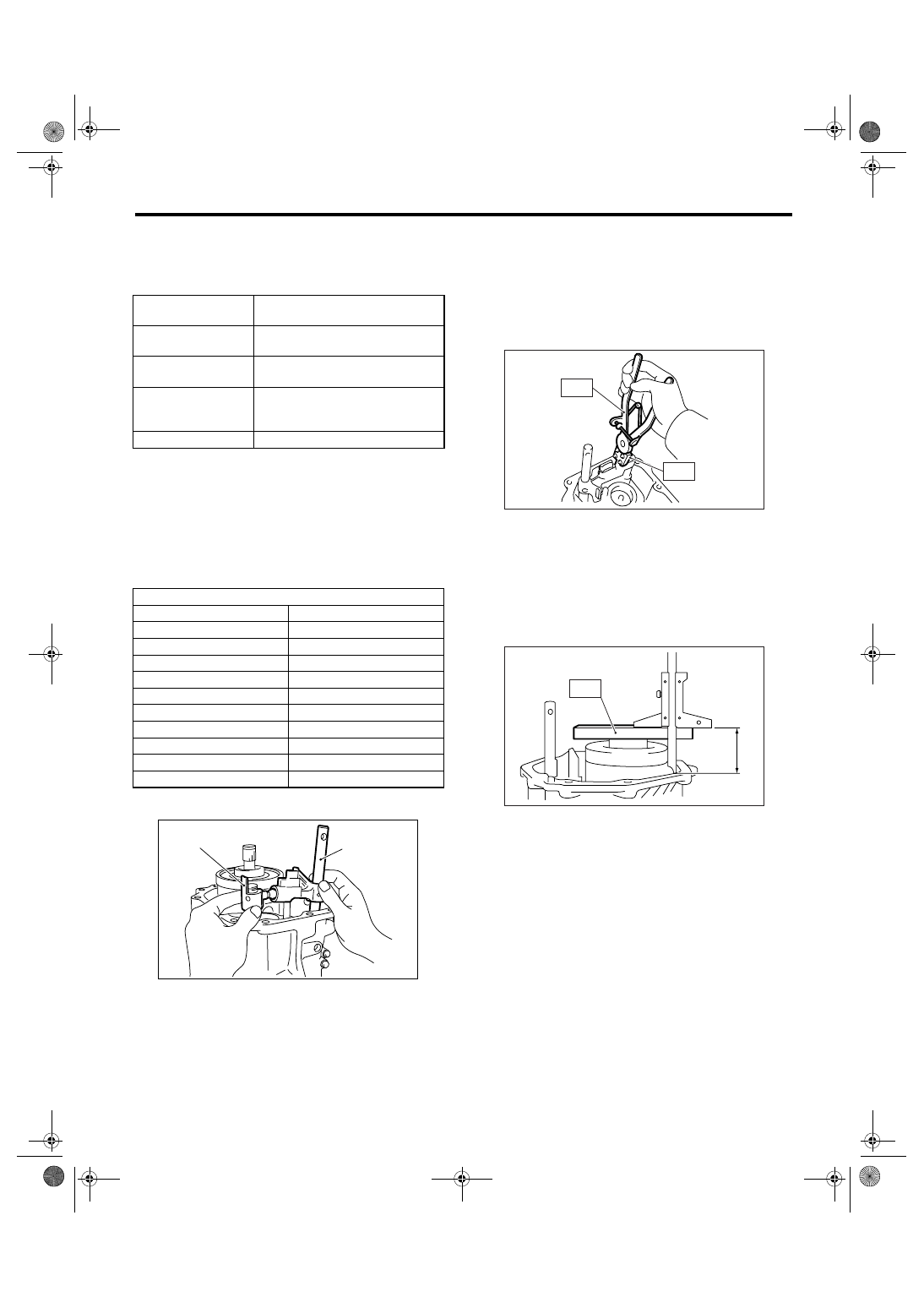

16) Remove the selector arm No. 2 and shifter arm.

17) Install the spring pin.

NOTE:

Use new spring pin.

18) Using the ST, install the neutral set spring and

support.

ST1

18756AA000 CLAW

ST2

399893600

PLIERS

19) Install the flat washer and snap ring.

20) Install the center differential.

2. SELECTING THE TRANSFER DRIVE

GEAR THRUST WASHER

1) Measure the height “Z” between end of transmis-

sion case and end of ST.

ST

499575500

GAUGE

2) Measure the depth “Y” between end of ST and

transfer drive gear.

t

mm (in)

Thickness of transfer driven gear

bearing thrust washer

Y

mm (in)

Depth from end of ST to bearing

cone

Z

mm (in)

Depth from end of extension case

to contact point of bearing cone

−0.04 — 0.11 mm

(

−0.0016 — 0.0043

in)

Standard clearance between thrust

washer and taper roller bearing

100 mm (3.94 in)

Height of ST

Thrust washer (50

× 61 × t)

Part No.

Thickness t mm (in)

803050060

0.50 (0.0197)

803050062

0.60 (0.0236)

803050064

0.70 (0.0276)

803050066

0.80 (0.0315)

803050068

0.90 (0.0354)

803050070

1.00 (0.0394)

803050072

1.10 (0.0433)

803050074

1.20 (0.0472)

803050076

1.30 (0.0512)

803050078

1.40 (0.0551)

(A) Selector arm No. 2

(B) Shifter arm

(B)

(A)

MT-01308

MT-01092

ST2

ST2

ST1

MT-00492

Z

ST