Subaru Legacy (2005 year). Service manual - part 93

LU(H4SO 2.0)-17

LUBRICATION

Oil Pan and Strainer

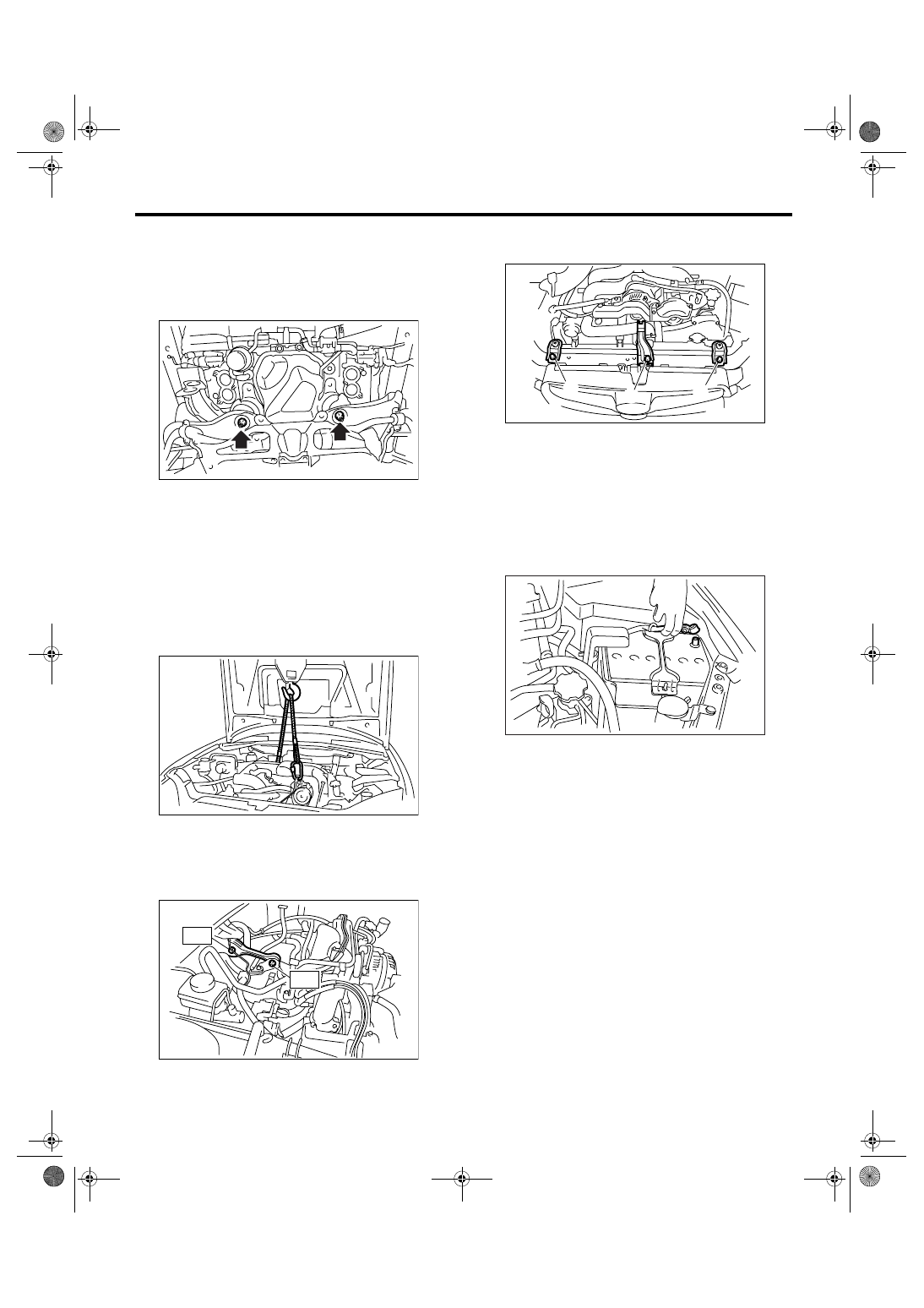

6) Lower the engine onto front crossmember.

7) Tighten the nuts which install front cushion rub-

ber onto front crossmember.

Tightening torque:

85 N

⋅

m (8.7 kgf-m, 62.7 ft-lb)

8) Install the front and center exhaust pipe. <Ref. to

EX(H4SO 2.0)-7, INSTALLATION, Front Exhaust

Pipe.> <Ref. to EX(H4SO 2.0)-9, INSTALLATION,

Center Exhaust Pipe.>

9) Install the under cover.

10) Lower the vehicle.

CAUTION:

When lowering the vehicle, lower the lift-up de-

vice and wire ropes at the same time.

11) Remove the lifting device and wire ropes.

12) Install the pitching stopper.

Tightening torque:

T1: 50 N

⋅

m (5.1 kgf-m, 36.9 ft-lb)

T2: 58 N

⋅

m (5.9 kgf-m, 42.8 ft-lb)

13) Install the hood stay holder (A) and radiator up-

per brackets (B).

14) Install the air intake chamber.

<Ref. to IN(H4SO 2.0)-7, INSTALLATION, Air In-

take Chamber.>

15) Install the air intake duct and air cleaner case.

<Ref. to IN(H4SO 2.0)-8, INSTALLATION, Air In-

take Duct.> <Ref. to IN(H4SO 2.0)-5, INSTALLA-

TION, Air Cleaner Case.>

16) Install the front wheels.

17) Connect the ground cable to battery.

18) Fill the engine oil. <Ref. to LU(H4SO 2.0)-9, IN-

SPECTION, Engine Oil.>

C: INSPECTION

Visually check that the oil pan, oil strainer, oil

strainer stay and baffle plate are not damaged.

LU-00223

LU-00222

LU-00233

T2

T1

LU-00232

(A)

(B)

(B)

IN-00203