SsangYong: Engine Euro 4. Service manual - part 15

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

11

1881

FUEL SUPPLY SYSTEM

D27DTP/D27DT (EU4) SM - 2006.08

D27DTP/D27DT (EU4)

ENGINE

FUEL

I

N

T

AKE

EXHAUST

PRE-HEA

TING

LUB

COOLING

SWITCHABLE

ECU

DIAGNOSIS

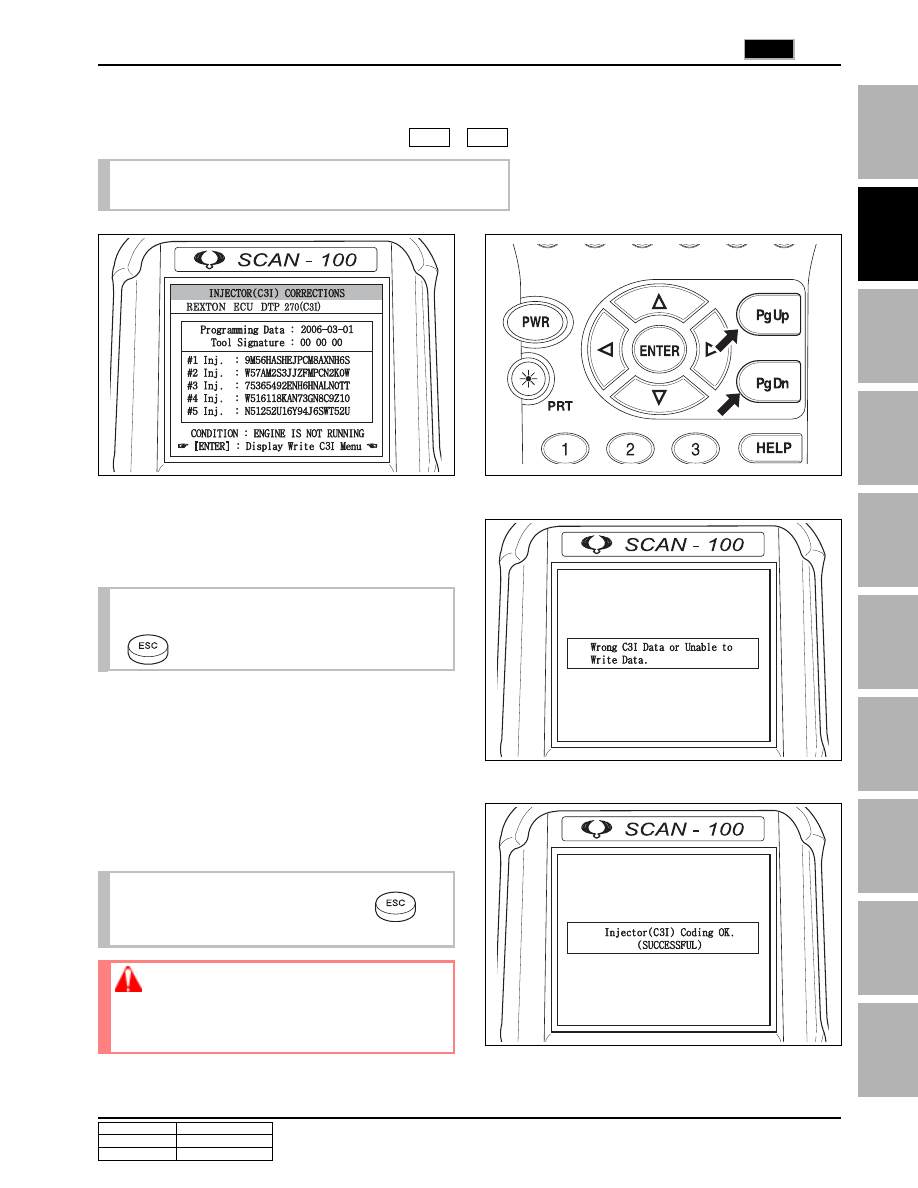

3-2. If you enter the invalid C2I or C3I value of the rel-

evant injector, the message as shown in figure ap-

pears with alarm sound.

3-1. If you press [ENTER] on C3I (C2I) display, the recoding menu of C3I or C2I appears.

C3I is coded by using alphabet letters up to Z. If you want to change a number in the coding letters, press the

number keypad of SCAN-100. If you press PgUp or PgDn key, you can enter alphabet letters again.

3-3. If you enter the valid C2I or C3I value of the relevant

injector, the message as shown in figure appears

with alarm sound.

• If you want to return to previous screen, press

key. You can see the previous C2I or C3I value.

NOTE

• If you return to previous screen, press

key.

Then, the new C2I or C3I values are displayed.

NOTE

• The alphanumeric letters are from A ~ Z followed by 0 ~ 9.

NOTE

• When coding C2I or C3I, if you select the engine

out of the models, the injector coding items per-

taining to the engine appear.

NOTICE