SsangYong Rexton. Service manual - part 593

SSANGYONG Y200

5D2-20 TRANSFER CASE - TOD

SYSTEM OPERATION

Initial Operation of TOD Control Unit

When ignition “ON”, “4L” and “4WD check” lamps

illuminates for 0.6 second to check bulb in instrument

panel, then perform diagnosis of system (See 3F-19

Self-Diagnosis Condition).

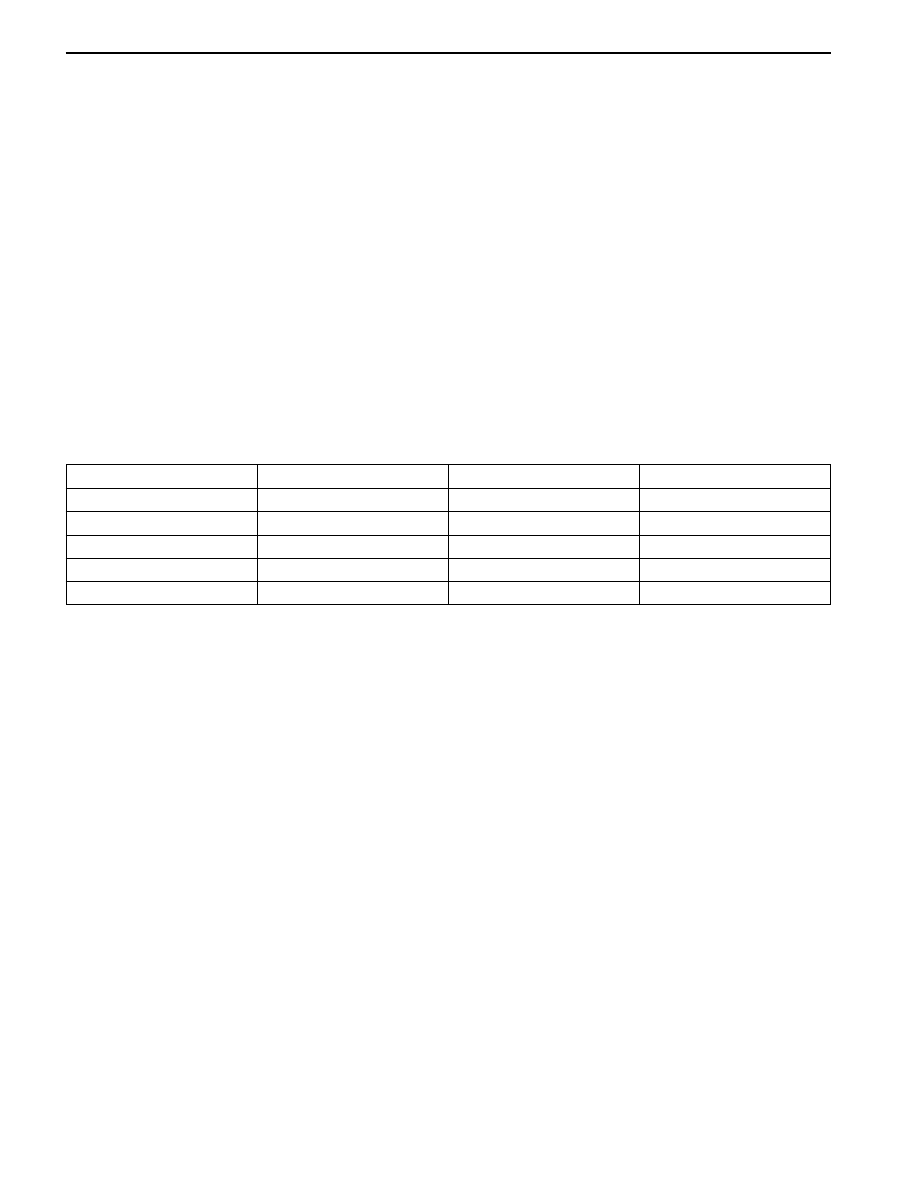

Position Encoder

The Position Encoder is used by the TOD to determine

the position of the Shift Motor. Each motor position is

identified by a position code below.

Notice:

•

All other position codes are invalid

•

Position

Input Open Circuit (> 4.5V) = 1

•

Position Input shorted to Speed/Position Return

(< 0.5V) = 0

Position Code 1/2/3/4

1110

1010

0010

0000

1110

Motor Position

Left Stop

Left of High

High

Right of High

Zone 1

Position Code 1/2/3/4

1001

0001

0101

0100

-

Motor Position

Neutral

Zone 2

Low

Right Stop

-