SsangYong Rexton. Service manual - part 556

AUTOMATIC TRANSMISSION 5A-199

SSANGYONG Y200

KAA5A2B0

KAA5A2A0

KAA5A510

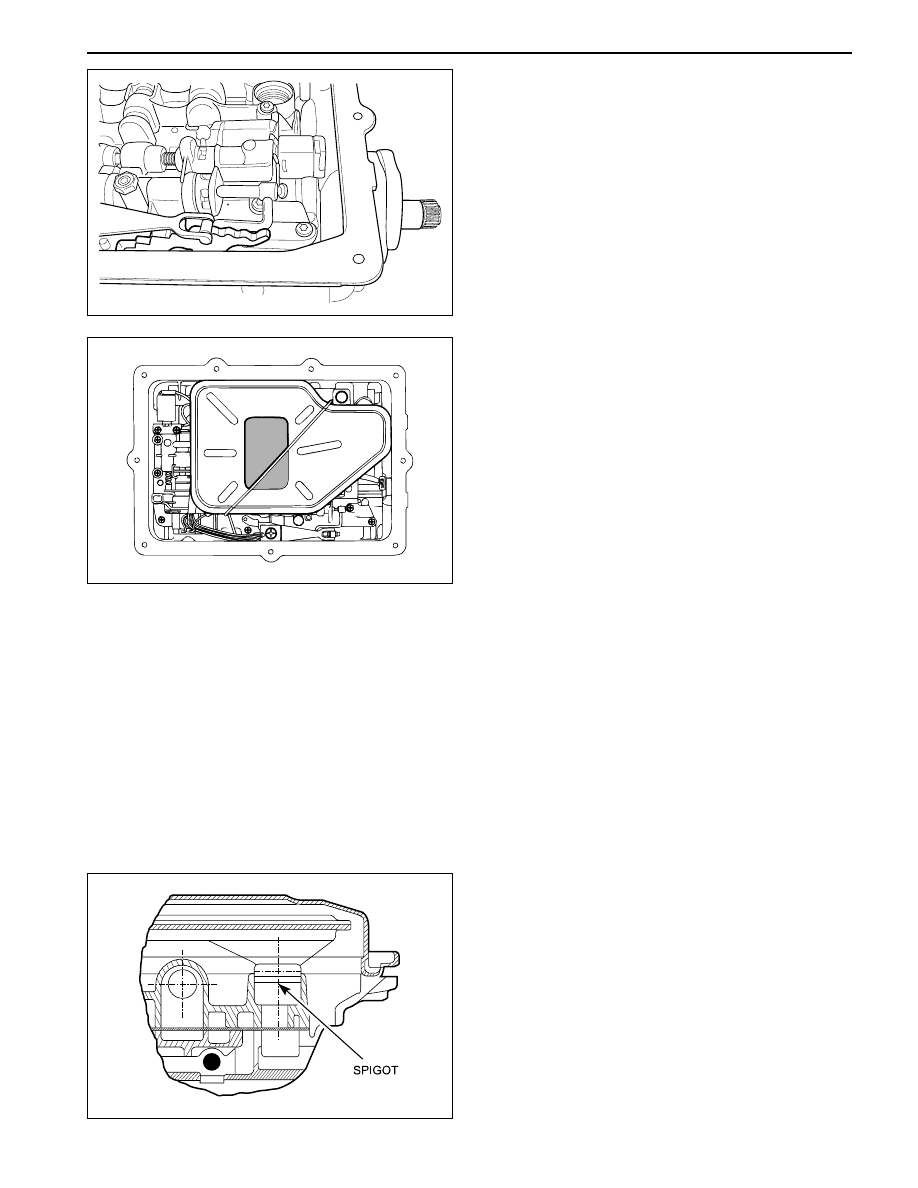

2. Carefully assemble the oil filter to the valve body.

The spigot must not lean on one side while being

fitted.

3. Secure the oil filter assembly with the retainer.

4. Check that the magnet is located in the dimple in

the corner of the oil pan.

5. Assemble the gasket on the pan lip. The gasket

must be free of any distortion when installed.

25. Check the alignment of the detent roller and the

manual lever quadrant.

26. Connect the solenoid wiring as detailed below:

Solenoid 1 - red

Solenoid 2 - bIue

Solenoid 3 - yellow

Solenoid 4 - orange

Solenoid 5 - green

Solenoid 6 - violet

Notice: All hardware must be correctly installed and

torqued to specification.

Oil Filter and Pan Assembly

Notice:

•

Replace the filter whenever rebuilding a

transmission where a significant amount of

mechanical damage has occurred.

•

To aid the assembly of the pan gasket, use a small

amount of Vaseline at the pan/gasket interface. This

ensures that the gasket remains on the pan ridge.

Do not over torque pan bolts as this may distort

the pan and cause leaks.

•

Ensure that the internal line pressure plus in the

valve body is fitted.

1. Lubricate the oil filter sealing ring with automatic

transmission fluid.