SsangYong Rexton. Service manual - part 546

AUTOMATIC TRANSMISSION 5A-159

SSANGYONG Y200

ON-VEHICLE SERVICE

TRANSMISSION

Removal and Installation Procedure

1. Disconnect the negative battery cable.

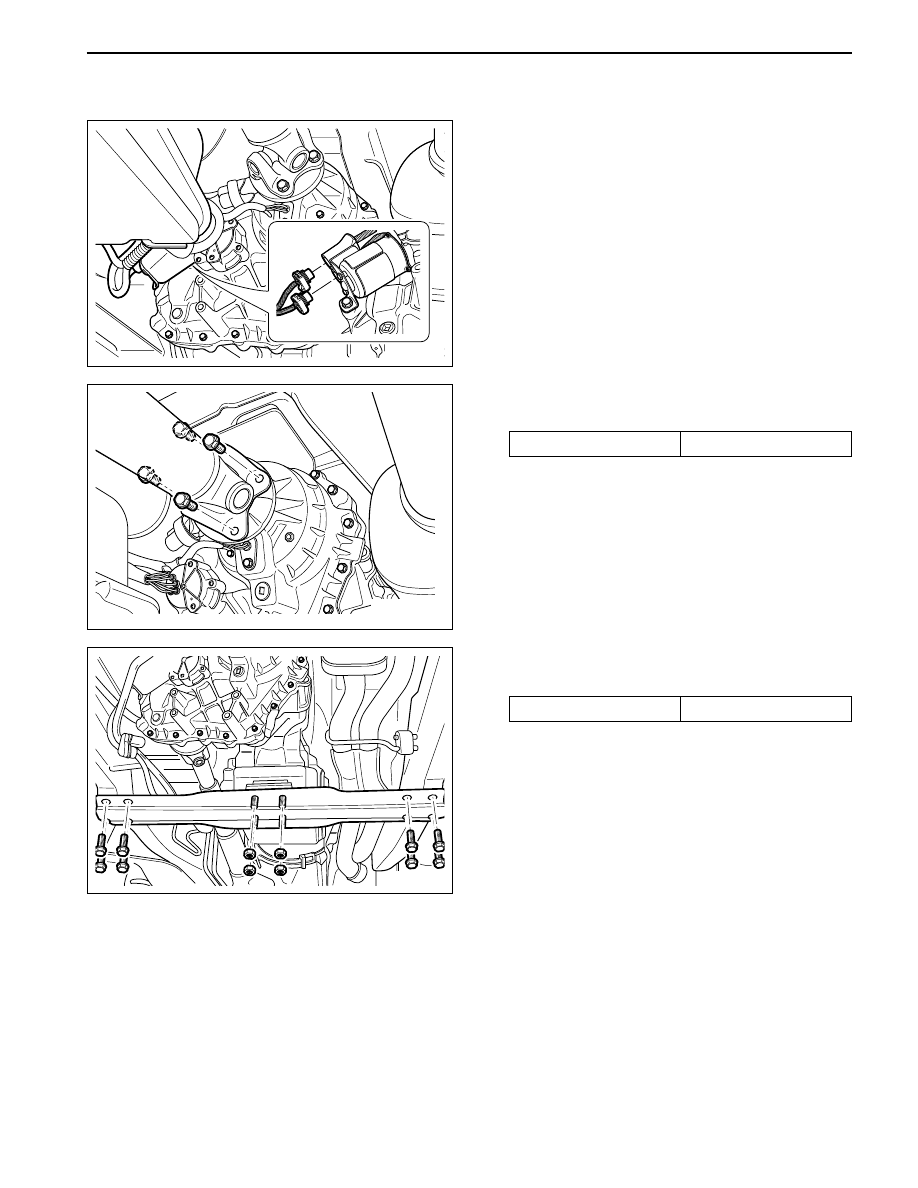

2. Disconnect the connectors from transfer case.

3. Disconnect the speedometer connector from

transfer case.

4. Disconnect the inhibitor connector, gear position

sensor connector and transmission case connector.

REPAIR INSTRUCTIONS

5. Remove the rear propeller shaft bolts.

Installation Notice

YAD5A080

YAD5A090

YAD5A100

6. Remove the cross member bolts and nuts.

Installation Notice

Tightening Torque

70-80 N•m (52-59 lb-ft)

Tightening Torque

70-80 N•m (52-59 lb-ft)