SsangYong Rexton. Service manual - part 541

AUTOMATIC TRANSMISSION 5A-35

SSANGYONG Y200

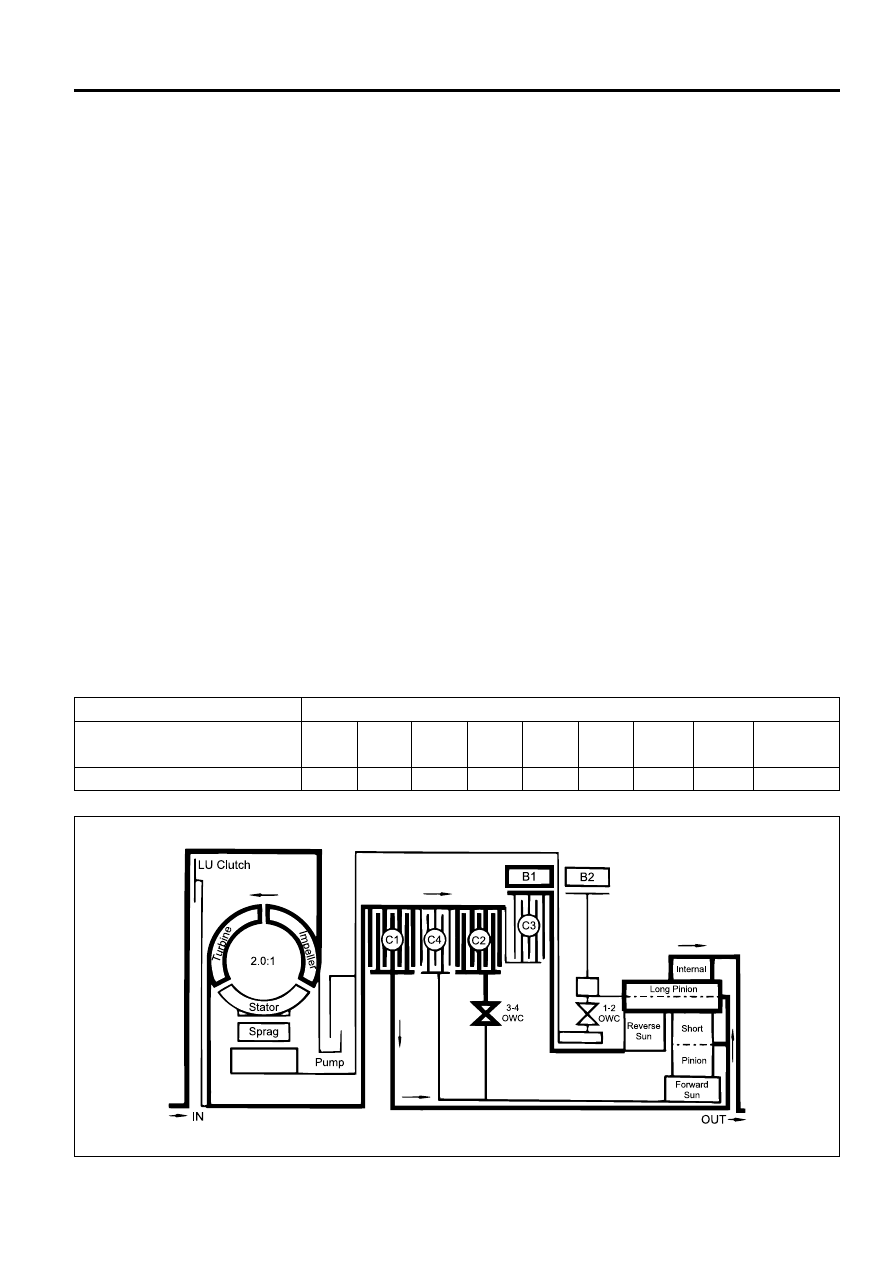

Power Flow - Drive 4 (Overdrive)

In Drive 4 (Overdrive), transmission drive is via the

input shaft to the forward clutch cylinder.

The elements of the transmission function as follows;

•

The C1 clutch is applied to drive the planet carrier

clockwise.

•

The B1 band is applied to hold the reverse sun gear

stationary.

•

As the planet carrier tuns, the long pinion walks

around the stationary reverse sun gear and rotates

around its axis driving the internal ring gear and

output shaft in a clockwise or forward direction at a

speed faster than the input shaft i.e. in overdrive

ratio.

•

The forward sun gear is also driven faster than the

input shaft and overruns the 3-4 OWC.

•

The C2 clutch is engaged to reduce the speed differ-

ential across the 3-4 OWC.

Control

To maintain this arrangement in the steady state sole-

noids and valves are activated as follows;

•

Solenoid S1 is switched ON. S2 is switched OFF.

•

With S1 switched ON, the 3-4 shift valve is held in

the fourth gear position by line 500 pressure on the

small end of the valve.

•

With S2 switched OFF, the 2-3 shift valve is held in

the fourth gear position by line 500 pressure on the

large end of the valve.

•

The 1-2 shift valve is held in the fourth gear position

by S2 oil pressure.

•

2nd oil (line pressure) from the 1-2 shift valve is di-

rected to the band apply feed regulator valve, and

to the 2-3 shift valve.

•

The band apply feed regulator valve supplies 2nd

oil (regulated to line pressure multiplied by the valve

ra-tio) to the Band Apply Feed (BAF) circuit.

•

Band apply feed oil is directed to;

- the outer apply area of the front servo

- the inner apply area of the front servo piston via

the 3-4 shift valve

- the 1-2 shift valve to provide an exhaust port

when the transmission is shifted to first gear

•

2nd oil at the 2-3 shift valve is directed to the 3rd

oil circuit.

•

3rd oil from the 2-3 shift valve is directed to the

clutch apply regulator valve, and to the 4-3

sequence valve.

•

The clutch apply regulator valve supplies oil (regu-

lated to line 500 pressure multiplied by the valve

ratio) to the Clutch Apply Feed (CAF) circuit.

•

The CAF oil is directed to;

- the C1 clutch

- the 4-3 sequence valve

•

Drive oil (line pressure) from the manual valve en-

gages the C2 clutch.

KAA5A460

Gear State

Drive 4 Overdrive

C1

X

C2

X

C3

-

C4

-

B1

X

B2

-

1-2

OWC

-

3-4

OWC

-

LU

CLUTCH

-

ELEMENTS ENGAGED