SsangYong Rexton. Service manual - part 533

AUTOMATIC TRANSMISSION 5A-3

SSANGYONG Y200

allows the engine to be started. There is no power

transferred through the transmission in Neutral. But

the final drive is not locked by the parking pawl, so

thewheels are free to rotate.

•

D - Overdrive range is used for all normal driving

conditions. 4th gear (overdrive gear) reduces the

fuel consumption and the engine noise. Engine

braking is applied with reduced throttle.

First to second (1

→

2), first to third (1

→

3), second

to third (2

→

3), second to fourth (2

→

4), third to

fourth (3

→

4), fourth to third (4

→

3), fourth to

second (4

→

2), third to second (3

→

2), third to

first (3

→

1) and second to first (2

→

1) shifts are

all available as a function of vehicle speed, throttle

position and the time change rate of the throttle

position.

Downshifts are available for safe passing by

depress-ing the accelerator. Lockup clutch may be

enabled in 3rd and 4th gears depending on vehicle

type.

•

3 - Manual 3 provides three gear ratios (first through

third) and prevents the transmission from operating

in 4th gear. 3rd gear is used when driving on long

hill roads or in heavy city traffic. Downshifts are

available by depressing the accelerator.

•

2 - Manual 2 provides two gear ratios (first and

second). It is used to provide more power when

climbing hills or engine braking when driving down

a steep hill or starting off on slippery roads.

•

1 - Manual 1 is used to provide the maximum engine

braking when driving down the severe gradients.

When NORMAL mode is selected upshifts will occur

to maximize fuel economy. When POWER mode is se-

lected, u p s h i f t s w i l l o c c u r t o g i v e m a x i m u m

performance and the POWER mode indicator light is

switched ON.

When WINTER mode is selected, starting in second

gear is facilitated, the WINTER mode indicator light is

switched ON and the POWER mode indicator light is

switched OFF.

Indicator Light

The indicator light is located on the instrument panel.

•

Auto shift indicator light comes ON when the ignition

switch ON and shows the gear shift control lever

posi-tion.

•

POWER mode indicator light comes ON when the

POWER mode is selected and when the kickdown

switch is depressed.

•

WINTER mode indicator light comes ON when the

WINTER mode is selected.

CONTROL SYSTEMS

BTRA M74 4WD automatic transmission consists of

two control systems. One is the electronic control

system that monitors vehicle parameters and adjusts

the transmission performance. Another is the hydraulic

control system that implements the commands of the

electronic control system commands.

ELECTRONIC CONTROL SYSTEM

The electronic control system comprises of sensors, a

TCM and seven solenoids. The TCM reads the inputs

and activates the outputs according to values stored

in Read Only Memory (ROM).

The TCM controls the hydraulic control system. This

control is via the hydraulic valve body, which contains

seven electromagnetic solenoids. Six of the seven

solenoids are used to control the line pressure, operate

the shift valves and the torque converter lock-up clutch,

and to turn ON and OFF the two regulator valves that

control the shift feel.

The seventh solenoid is the proportional or Variable

Pressure Solenoid (VPS) which works with the two regu-

lator valves to control shift feel.

Transmission Control Module (TCM)

The TCM is an in-vehicle micro-processor based trans-

mission management system. It is mounted under the

driver’s side front seat in the vehicle cabin.

The TCM contains:

•

Processing logic circuits which include a central mi-

croprocessor controller and a back-up memory

system.

•

Input circuits.

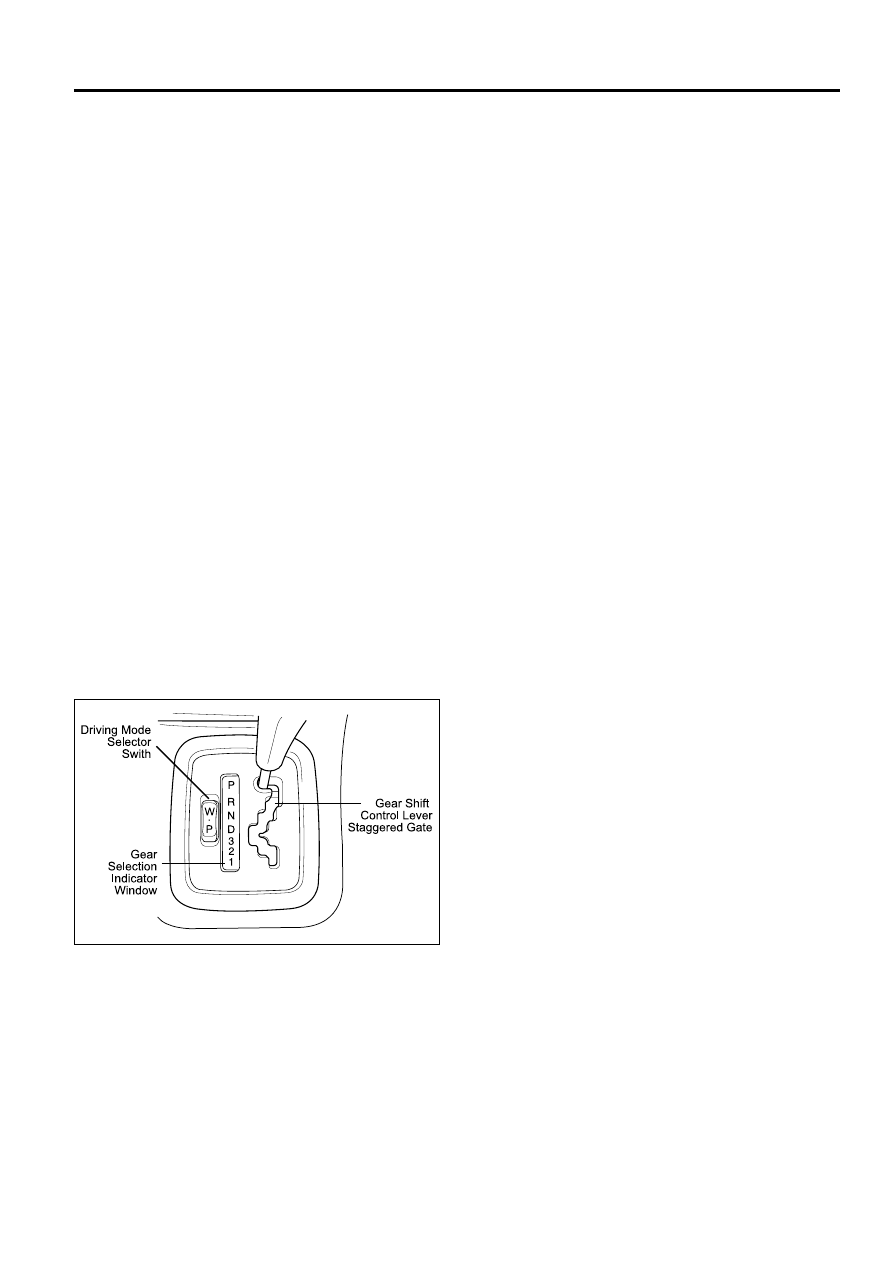

Driving Mode Selector

The driving mode selector consists of a driving mode

selector switch and indicator light. The driving mode

selector is located on the center console and allows

the driver to select the driving mode.

The driving modes available to be selected vary with

vehicle types. Typically the driver should have the

option to select among NORMAL, POWER and

WINTER modes.

KAA5A020