SsangYong Rexton. Service manual - part 452

SSANGYONG Y200

1F3-28 DIESEL ENGINE CONTROLS

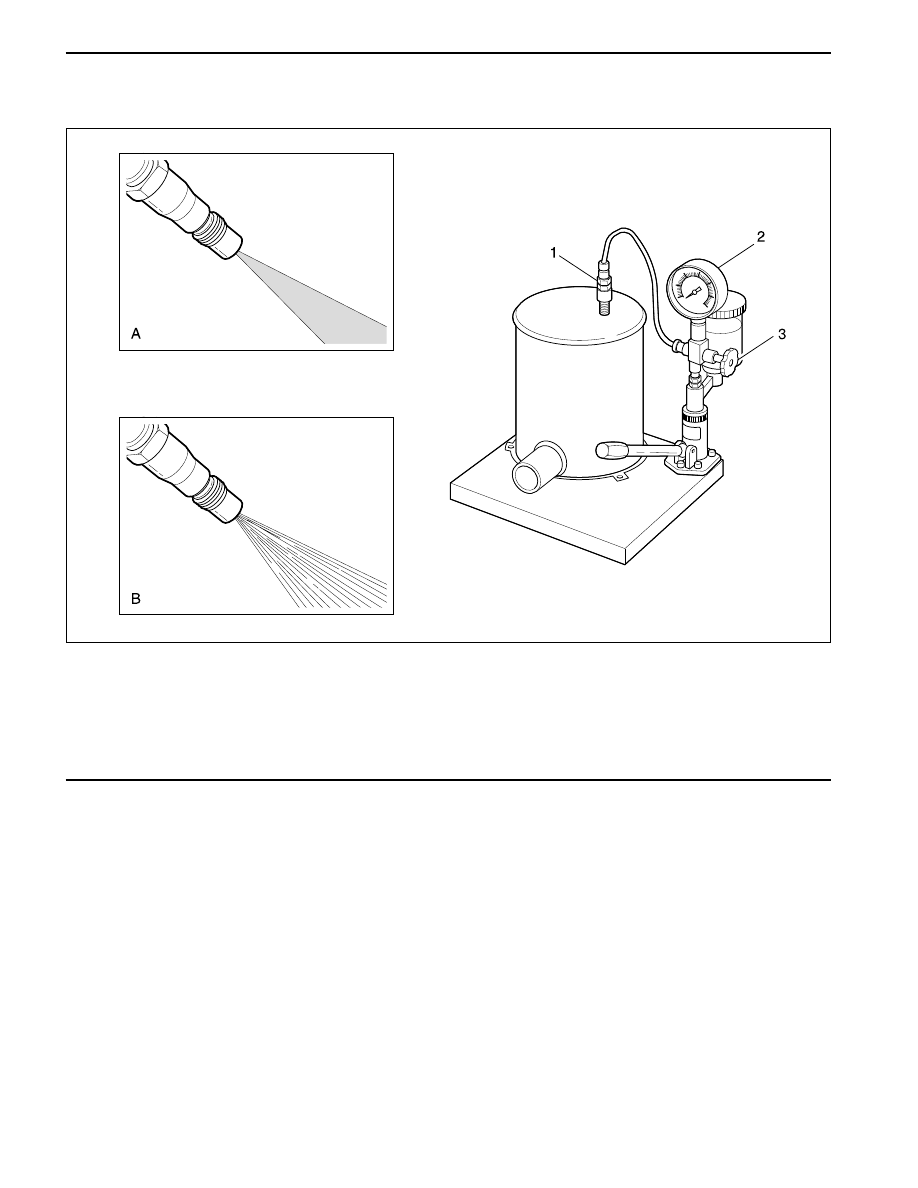

INJECTION NOZZLE TEST

Preceding Work: Removal of fuel injection nozzle

1 Fuel Injection Nozzle ........... New : 135 - 143 bar

............................................ Used : min. 120 bar

A Closed Spray = good

B Stringy Spray = poor

2 Tester

3 Valve

YAD1FBB0