SsangYong Rexton. Service manual - part 429

SSANGYONG Y200

1F2-36 M161 ENGINE CONTROLS

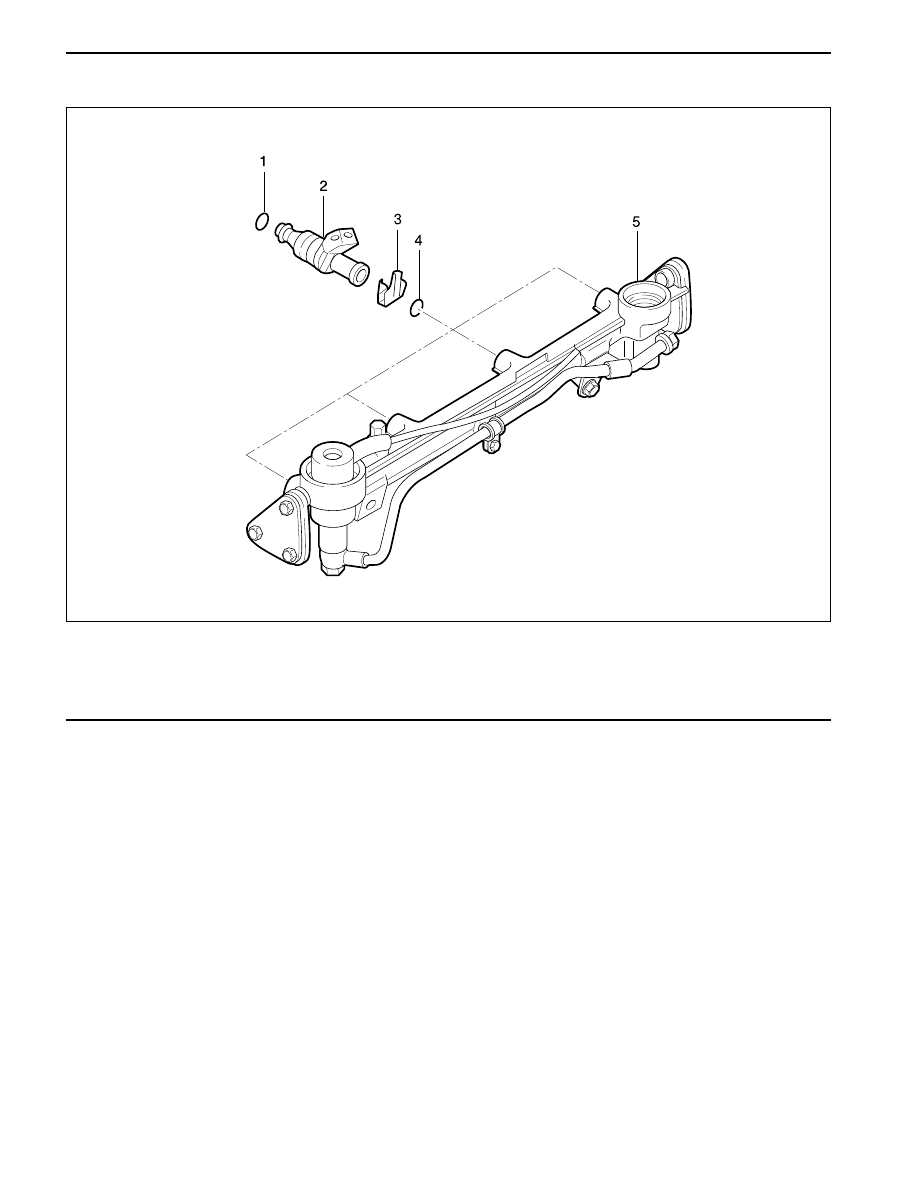

FUEL INJECTOR

YAA1F0C0

The Multipoint Fuel Injection (MFI) assembly is a solenoid-operated device controlled by the Engine Control

Module (ECM) that meters pressurized fuel to an each individual cylinder. The injector sprays the fuel, in precise

quantities at a point in time determined by the ECM, directly towad the cylinder intake valve. ECM energizes the

fuel injector solenoid to lift the needle valve and to flow the fuel through the orifice. This injector’s discharge

orificeis calibrated to meet the effective fuel atomization necessary for both ensuring the maximum homogeneity

in the air-fuel mixture and holding the condensation along the walls of the intake tract to a minimum.

Fuel enters the top feed injector from above and flows through its vertical axis. The lower end extends into the

intake valve. Fuel from the tip is directed at the intake valve, causing it to become further atomized and vaporized

before entering the combustion chamber.

A fuel injector which is stuck partially open would cause a loss of fuel pressure after the engine is shut down.

Also, an extended crank time would be noticed on some engines. Dieseling could also occur because some fuel

could be delivered to the engine after the ignition is turned off.

1 O-Ring

2 Injector

3 Injector Bracket

4 O-Ring

5 Fuel Rail