SsangYong Rexton. Service manual - part 417

SSANGYONG Y200

1F1-86 M162 ENGINE CONTROLS

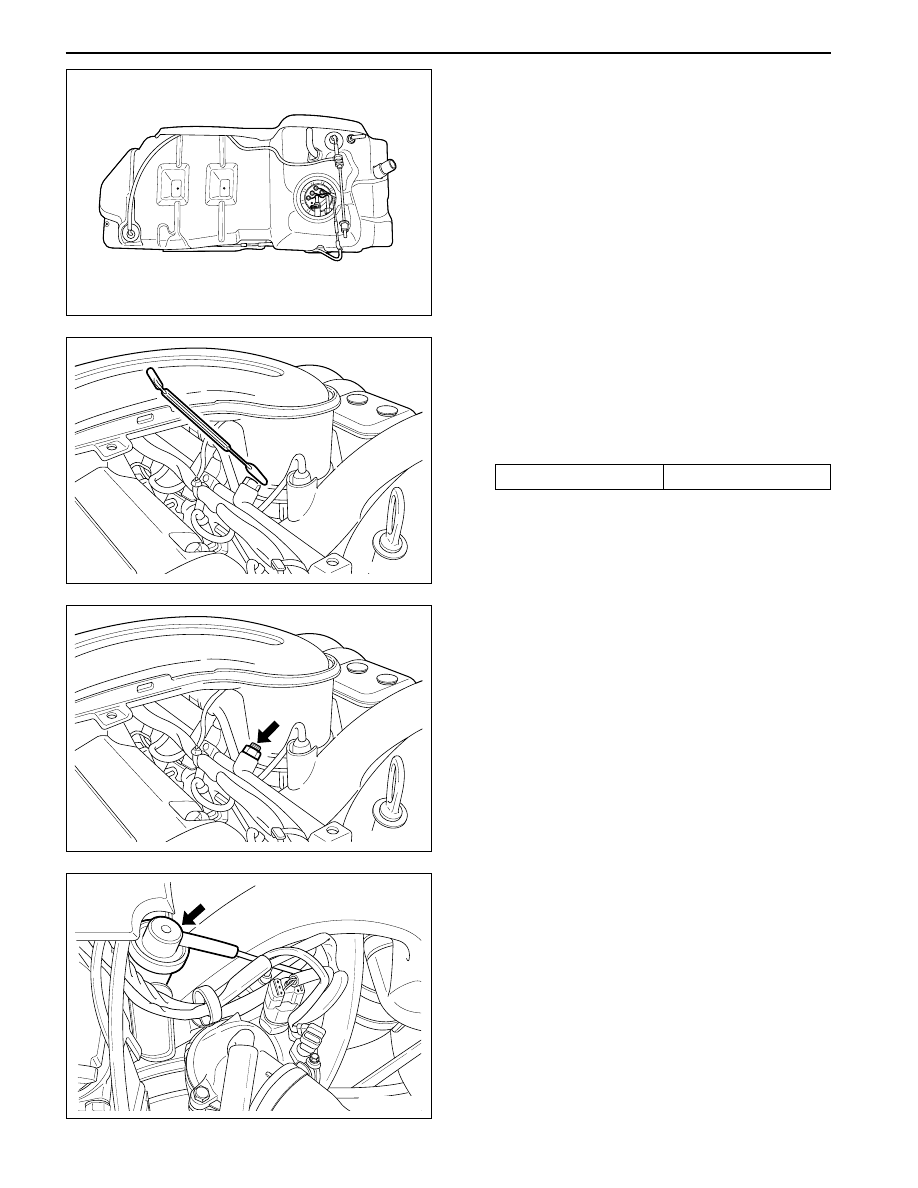

YAA1F180

KAA1F430

KAA1F440

KAA1F130

14. Turn the roll over valves counterclockwise at an

angle of 90 degrees.

15. Turn the lock ring counterclockwise.

16. Remove and discard the gasket.

17. Installation should follow the removal procedure

in the reverse order.

4. Disconnect the vacuum hose.

5. Disconnect the circlip and remove the fuel

pressure regulator.

6. Apply the oil to O-ring lightly and then replace it.

7. Perform a leak test of the fuel pressure regulator

with the engine off and the ignition on.

8. Installation should follow the removal procedure

in the reverse order.

Caution: The fuel system is under pressure. To avoid

fuel spillage and the risk of personal injury or fire,

it is necessary to relieve the fuel system pressure

before disconnecting the fuel lines.

3. Relieve the fuel pressure in fuel supply system

by pressing the service valve.

FUEL PRESSURE REGULATOR

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Remove the fuel pressure test connector.

Installation Notice

Tightening Torque

25 N•m (18 lb-ft)