SsangYong Rexton. Service manual - part 144

DI10-181

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

DIAGNOSIS

DI ENG SM - 2004.4

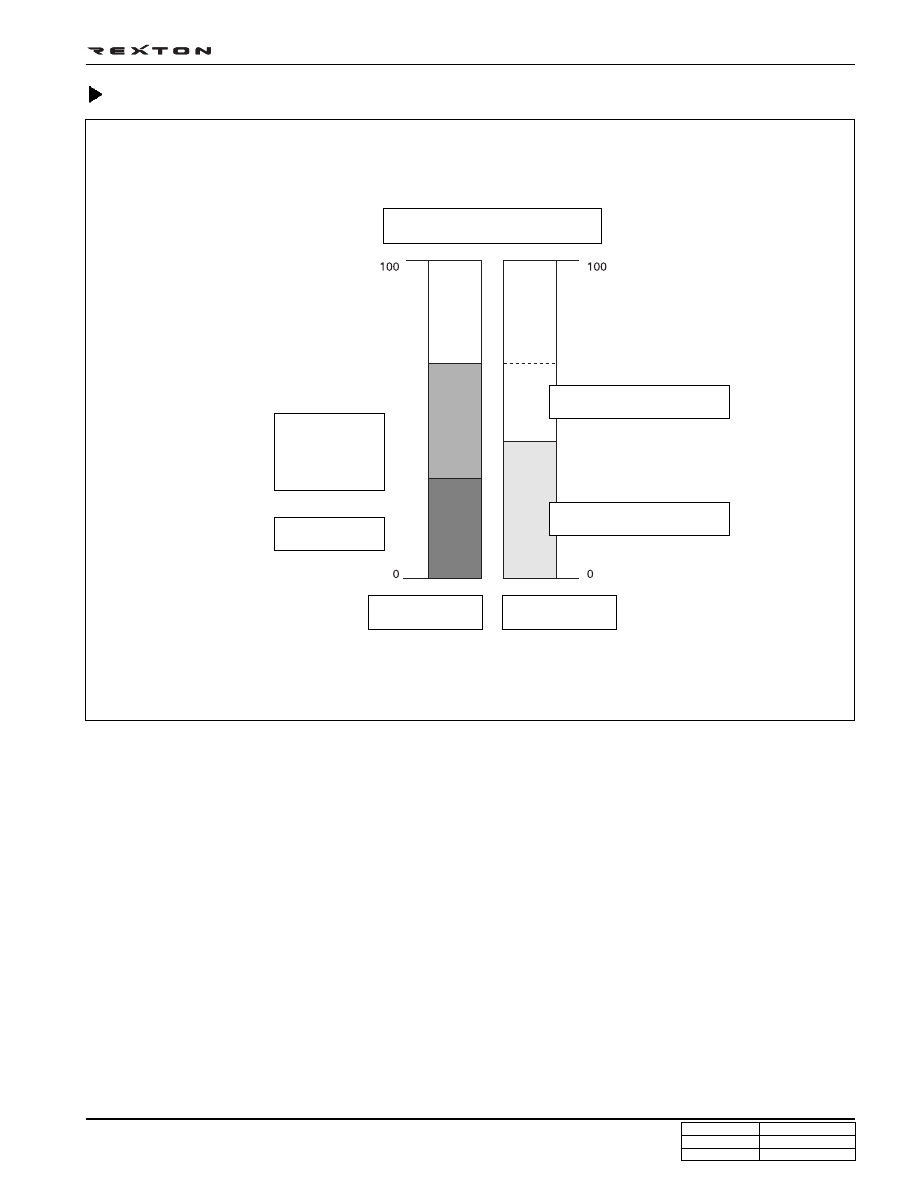

Example of Pressure/Volume Loss in Pump

Pressure/Volume Loss in High Pressure Pump

When the required target pressure/volume cannot be delivered due to fuel supply line or pump damage

Ex.:

• Air in fuel supply line

• Excessive vacuum pressure in fuel supply line (-300 mbar)

• Burnt out or mechanically damaged pump

• Supply fuel with increased temperature ( > 65°C)

Y220_10065

Decreased pressure/volume from

pump

Pressure/volume loss

Pump capacity

Pressure/volume

build up

Pressure/volume

consumption

Fuel injection

volume

Injector back

leak volume