SsangYong Rexton. Service manual - part 89

DI08-9

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

ENGINE CONTROL SYSTEM

DI ENG SM - 2004.4

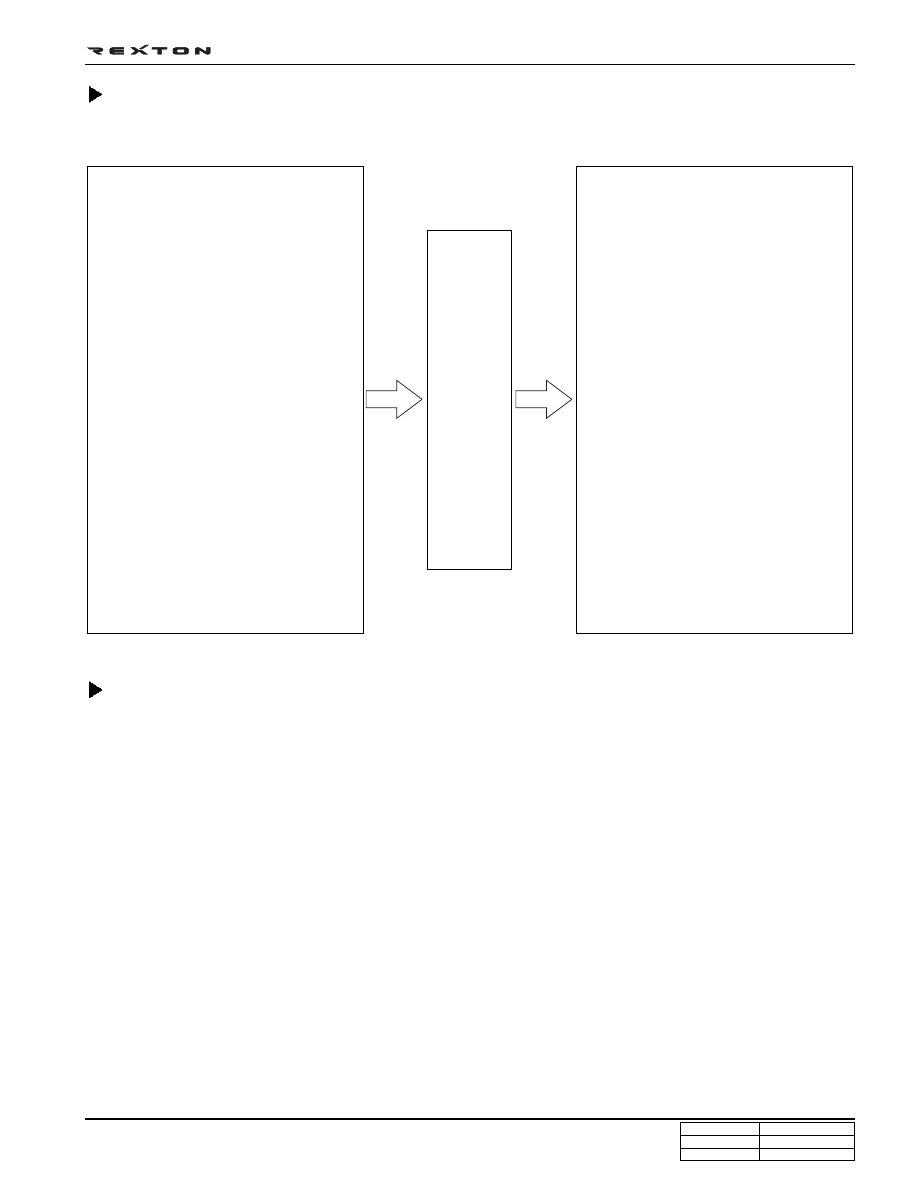

ECU Inputs·Outputs

Control

E

C

U

Structure and Function of ECU

Function of ECU

ECU receives and analyzes signals from various sensors and then modifies those signals into permissible voltage levels

and analyzes to control respective actuators.

ECU microprocessor calculates injection period and injection timing proper for engine piston speed and crankshaft

angle based on input data and stored specific map to control the engine power and emission gas.

Output signal of the ECU microprocessor drives pressure control valve to control the rail pressure and activates

injector solenoid valve to control the fuel injection period and injection timing; so controls various actuators in

response to engine changes. Auxiliary function of ECU has adopted to reduce emission gas, improve fuel economy

and enhance safety, comforts and conveniences. For example, there are EGR, booster pressure control, autocruise

(export only) and immobilizer and adopted CAN communication to exchange data among electrical systems

(automatic T/M and brake system) in the vehicle fluently. And Scanner can be used to diagnose vehicle status and

defectives.

Operating temperature range of ECU is normally -40 ~ +85°C and protected from factors like oil, water and electromag-

netism and there should be no mechanical shocks.

To control the fuel volume precisely under repeated injections, high current should be applied instantly so there is

injector drive circuit in the ECU to generate necessary current during injector drive stages.

Current control circuit divides current applying time (injection time) into full-in-current-phase and hold-current-phase and

then the injectors should work very correctly under every working condition.

Output

Injector

EGR system

Fuel pressure regulating valve (IMV)

Electrical fan control (Low/High-speed)

A/C compressor relay

Glow plug relay

Immobilizer

Warning lights

(Water warning light, glow plug indica-

tor light, engine warning light)

Preheater (auxiliary heater)

K - line

CAN communication

Self-diagnosis

Inputs

Booster pressure sensor

Atmospheric pressure sensor

(Built-in ECU)

Air flow sensor (HFM)

Coolant temperature sensor

Fuel temperature sensor

Fuel pressure sensor

Fuel filter water sensor

Knock sensor

crankshaft position sensor

camshaft position sensor

Accelerator sensor

Vehicle speed sensor

Switch input signal

(IG, brake, clutch, A/C signal, A/C

compressor)