SsangYong Rexton. Service manual - part 72

DI07-4

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

FUEL SYSTEM

DI ENG SM - 2004.4

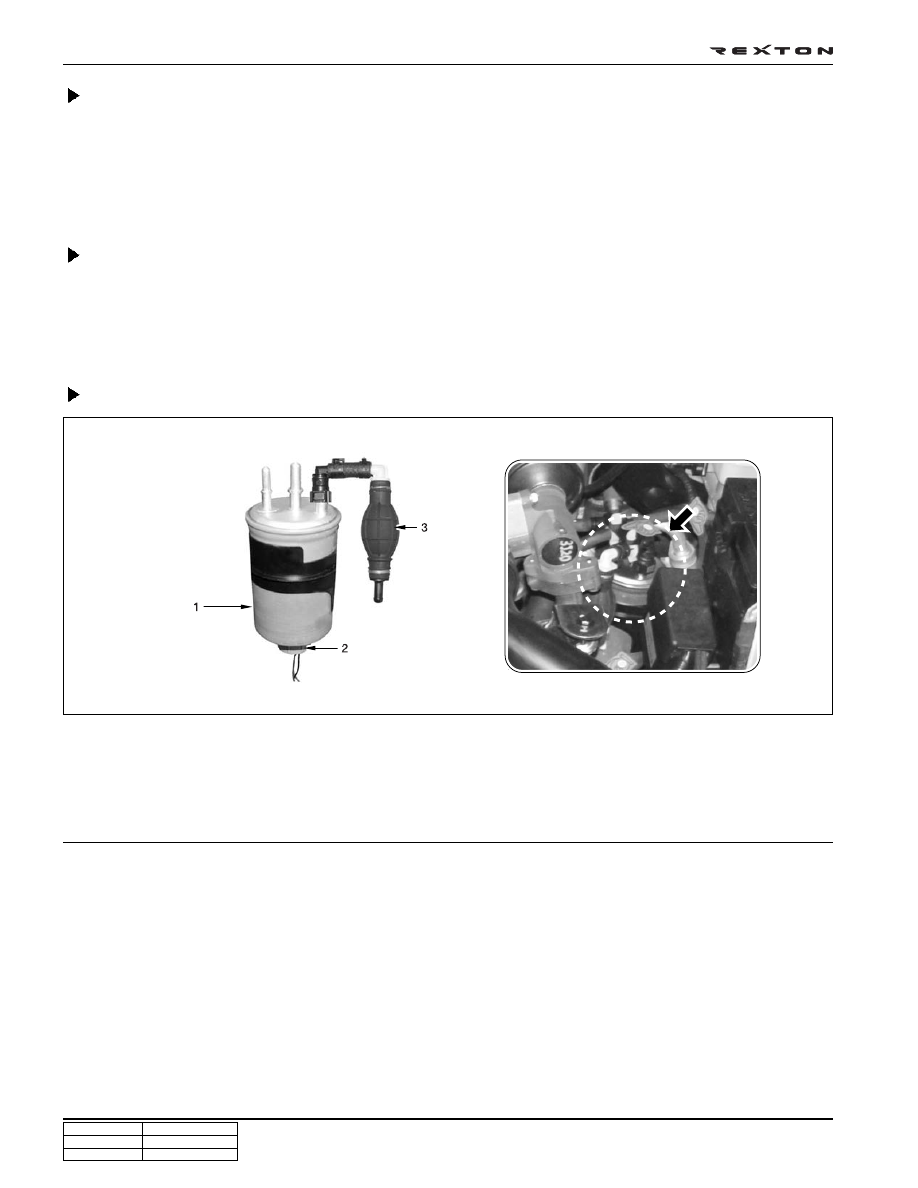

Priming Pump

The priming pump installed in fuel pump is the device to fill the fuel into the fuel filter. When the vehicle is under the

conditions as below, press the priming pump until it becomes rigid before starting the engine.

Y220_07003

1. Fuel filter

3. Priming pump

Notice

• When replaced the fuel filter or drained the water from fuel filter, press the priming pump until it becomes

rigid before starting the engine.

• The water drain from fuel filter should be performed whenever changing the engine oil.

2. Water drain plug

(to be drained every 15,000km max.)

Draining could be done at same time than oil

change

Conditions for using Priming Pump

1. After run out of fuel

2. After draining the water from fuel separator

3. After replacing filter or any intervention on system

Fuel Filter and Water Separator

WARNING

Never reverse filter or use it in other place (clean side)