SsangYong Rexton. Service manual - part 34

DI02-27

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

ENGINE HOUSING

DI ENG SM - 2004.4

Y220_02086

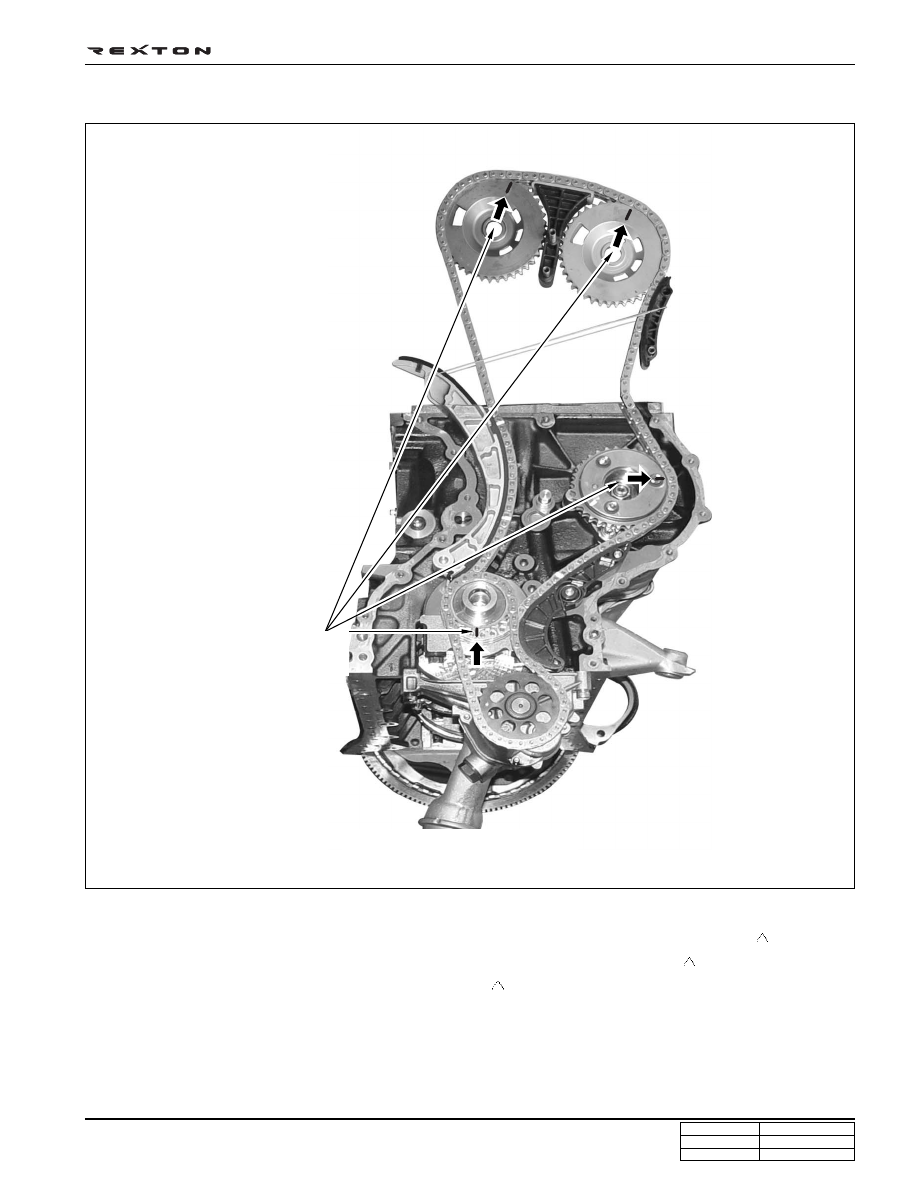

Timing setting

• Check marking links on the chain (Gold marking)

• Locate a point with two continuous marking links and align it to a marking on crankshaft sprocket (

)

• Align respective marking link to each camshaft sprocket (intake and exhaust) marking (

)

• Align another marking link to HP pump sprocket marking (

)

<Timing marking points on chain>

Sprocket marking: 4 points

(Gold marking)