Dacia Pick-Up 1304/1305/1307. Service manual - part 104

LOWER STRUCTURE

41

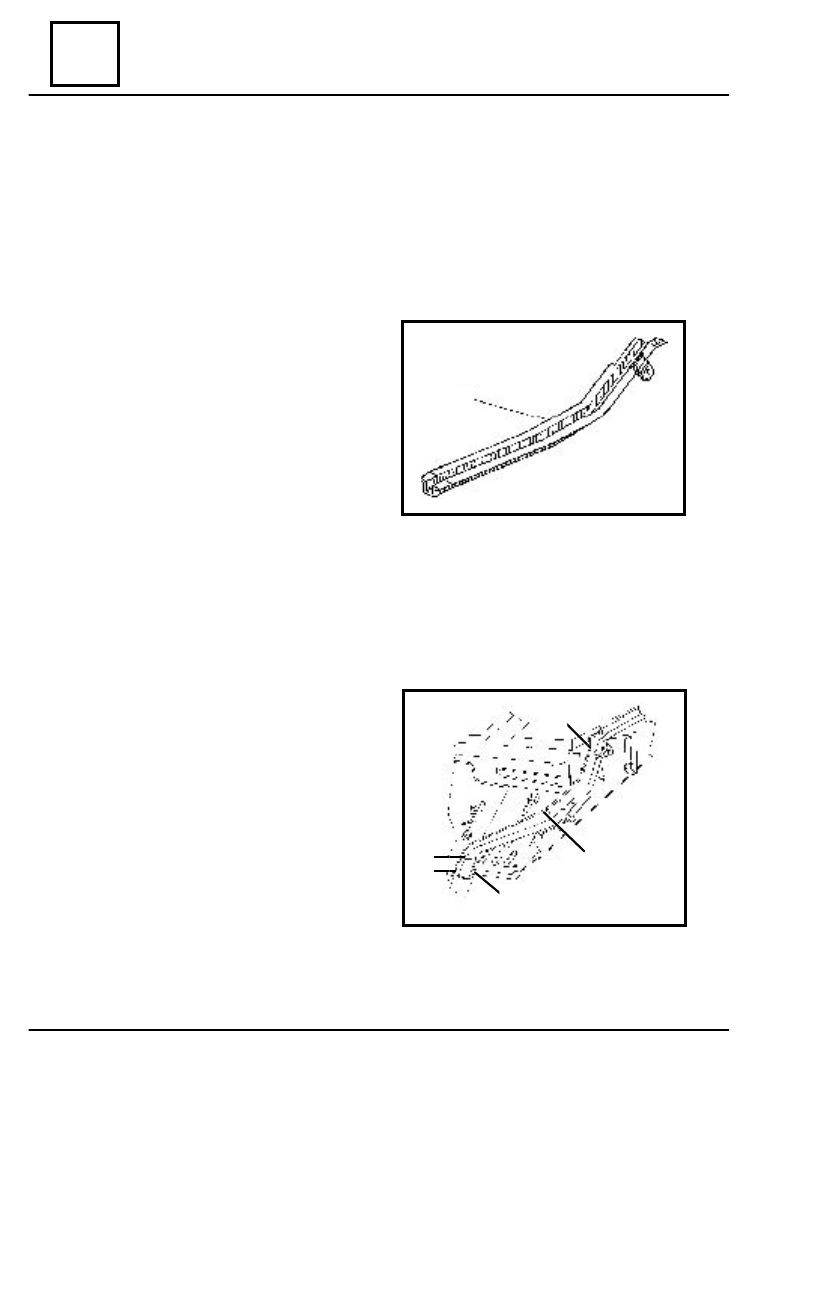

INTERMEDIARY LONGITUDINAL GIRDER

REPLACEMENT

This operation shall be performed only on the repair bench. For the specific supports

mounting on the bench, please see the 40 chapter.

D

ISMO UNTING

Dismount the elements, which are in contact

with the intermediary longitudinal girder.

Detach the welding points of the intermediary

longitudinal girder (1) that are connecting with:

- the longitudinal girder in the area (4);

- the pedal floor in the area (2);

- the lateral cross bar in the area (3);

- the central floor in the area (5);

- rear longitudinal girder in the area (7).

Straighten the areas resulted by dismounting.

Grind the areas resulted by dismounting.

Position and center the new element.

Check the correct positioning of the

intermediary longitudinal girder.

Weld the intermediary longitudinal girder

following the assembly outliners 2,3,4,5,6.

Protect the new element with a corrosion

preventing and noise absorbent product.

R

EMO UNTING

41 - 4

1

5

6

4

2

3