Dacia Pick-Up 1304/1305/1307. Service manual - part 84

33

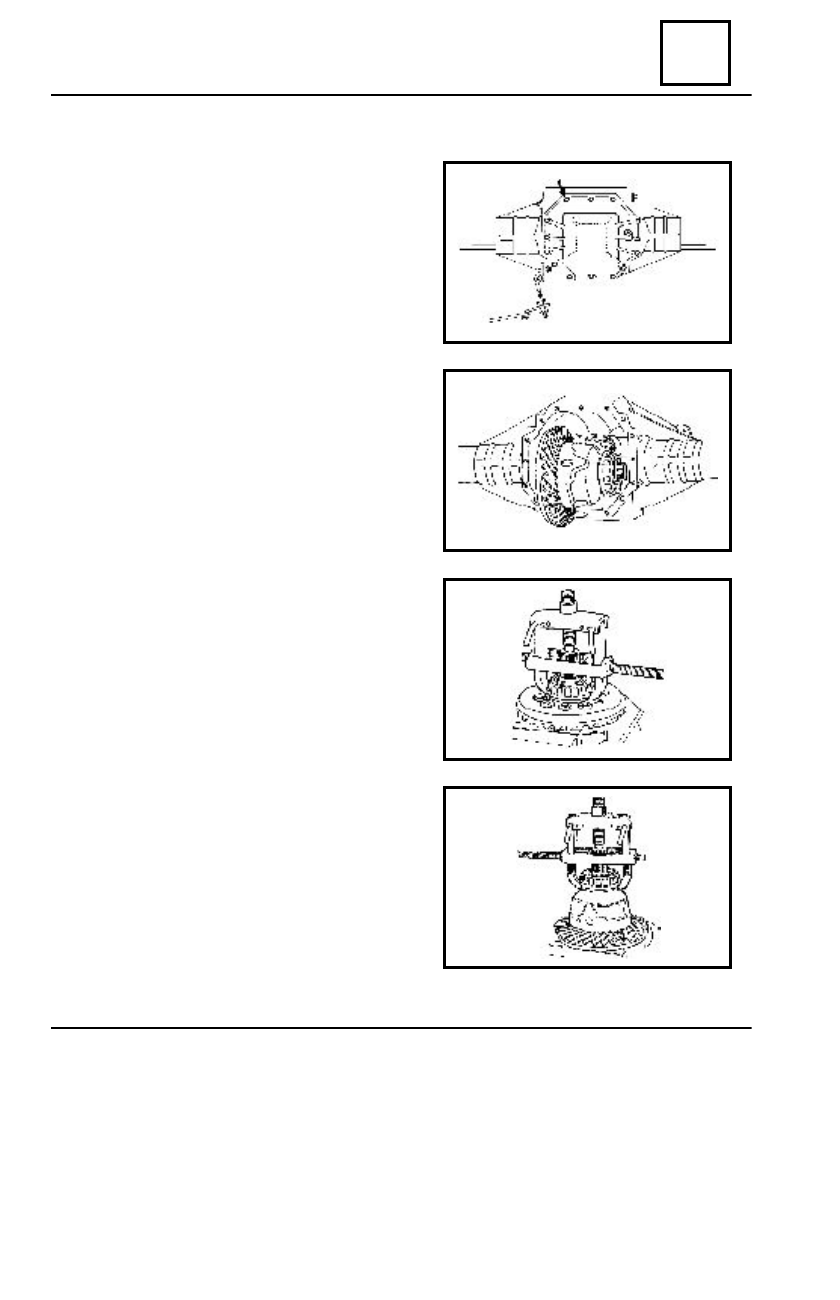

REAR BEARING ELEMENTS

33 - 27

CAST IRON REAR DRIVE AXLE DIFFERENTIAL

From the back part of the axle dismount the

cap of the axle , by unscrewing the fourteen M 8

screws.

Remove the G 3 – 36 and G 5 – 36 elastic

pins of the slotted bushing , by means of the 31

B set of mandrels, marking the position of the

bushing and shifting it towards the exterior.

Dismount the adjustment nuts retainers, mark-

ing the position of the nuts in correspondence

with the casing.

Unscrew the bearings nuts.

Dismount the bearings half casings by

unscrewing the M 10 screws.

Remove the differential gear assembly from

the rear axle casing, together with the two bi-

conical balls bearings.

From the back part of the axle also remove

the differential drive pinion together with the 35

x 80 x 32,75 conical balls bearing.

Dismount the two opposite screws that

attach the rim.

Depress the bearings by means of the

CV 28 A provided with CV 48 grippers.

Dismount the rim ; the screws shall not be

reused.