Dacia Pick-Up 1304/1305/1307. Service manual - part 63

29

DRIVE SHAFTS

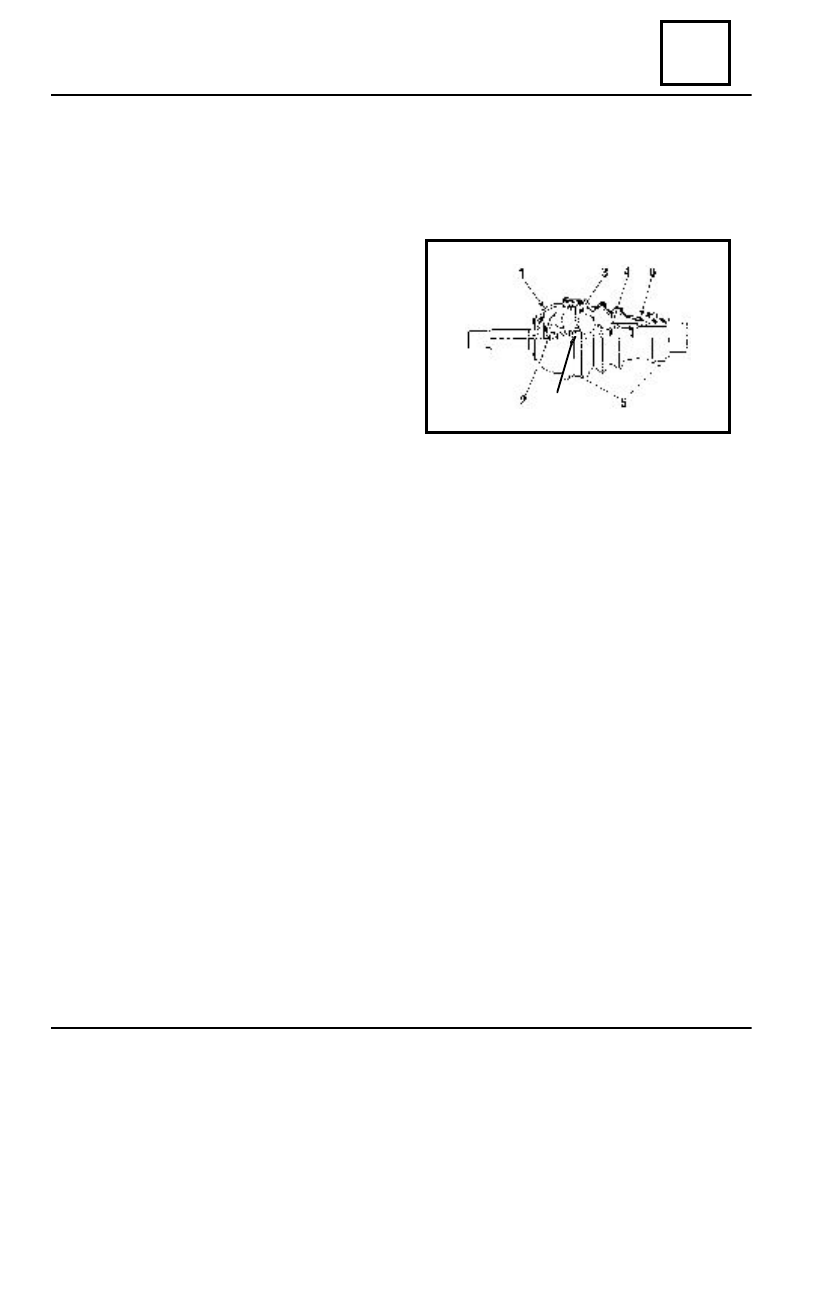

BELLOWS TOWARDS THE WEEL

GE 86 JOINT BELLOWS REPLACEMENT

Bellows replacement – the wheel side- is to be performed having the transmission

dismounted.

1

. Steering knuckle casing

2

. Retention star

3

. Tripod assembly

4

. Tulip shaft

5

. Collars

6

. Bellows

7

. Spring

D

ISMO UNTING

Remove the two collars (5) taking care not to damage the channels made on the steering

knuckle surface.

Cut and remove the damaged bellows.

Take out maximum of grease.

For GE joint bellows replacement it will be necessary to dismount the joint parts

towards the gearbox (joint JI 69) ( see previously described method).

R

EMO UNTING

NOTE:

It is absolutely necessary to observe the prescribed grease quantity ( 26,0 cl ).

Position: the bellows reinforcements in the steering knuckle casing channels and in the shaft

rod channel.

Mount the GE joint collars.

Remount GI joint parts.

29 - 7

7