Dacia Pick-Up 1304/1305/1307. Service manual - part 40

IGNITION AND INJECTION

17

17 - 24

IMPORTANT:

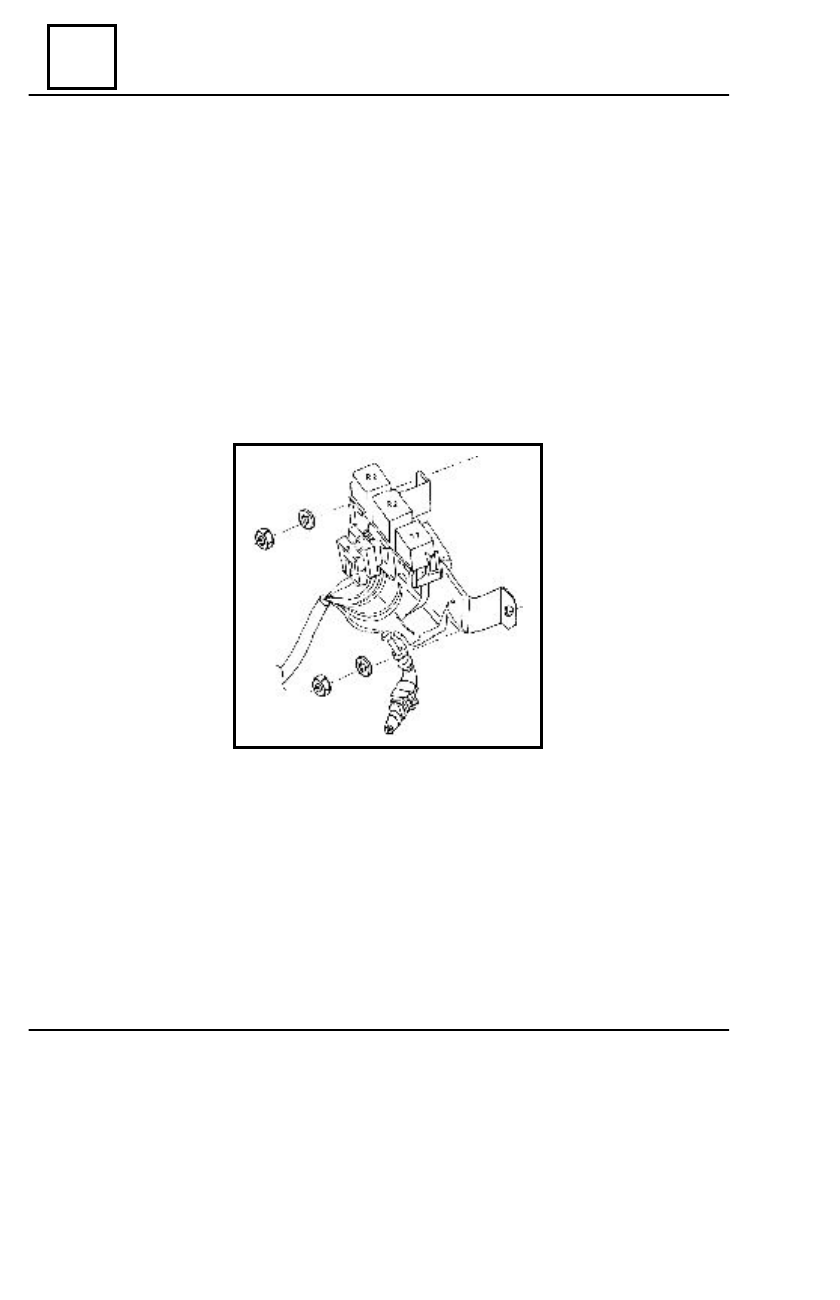

Two protecting relays and two fuses, placed on a fixed support on the front of the left mudguard

coating (front) electrically protect the injection system. The relays protect the supplying circuits

as follows:

- relay R1: for supplying the fuel electric pump the heating resistance of the oxygen rod an

the injector;

- relay R2: for supplying the computer (pin 17) and the injection witness of the vehicle

front panel;

- relay R3: for controlling the air conditioning compressor.

The plate fuses are 10 A; they are placed on the supplying circuit of the fuel electric pump

(S1) and of the oxygen rod (S2).

NECESSARY DEVICES FOR DIAGNOSIS AND MEASUREMENTS OF THE

SYSTEM PARAMETERS

- Voltmeter, ohmmeter, class 20000 Ù/V;

- Manometer for liquids, 0 – 4 bar, with T-connection;

- Tester SAGEM CLIP Dacia, KTS 300 or AT 520 with soft DACIA (MA 1.7) and

accessories for series diagnosis;

- Marked vessel 0 – 2000 ml.

DIAGNOSTIC