Dacia Pick-Up 1304/1305/1307. Service manual - part 19

10

10 - 42

ENGINE AND LOWER ENGINE UNITS

For all types of engines,the jackets shall be positioned as follows:

- the maximum difference between the heights of two adjoing jackets shall be

maximum 0,02 mm,within the limit of the prescribed tolerance;

- the jackets shall be placed in growing order ( by steps ).

After obtaining the correct height,the position of the jackets in the block is marked so that it

may be paired with the corresponding connecting rods.

For the engines where sealing is done by “ Cu “ made gaskets,the checking is done with

gaskets fitted.

Overheight of the gaskets over the gasket level : 0,05 – 0,13 mm. If the height of the jackets

over the gasket level is not within the prescribed limits, the jacket-block assembling values are to

be checked.

DISMOUNTING OF THE PISTON SHAFT

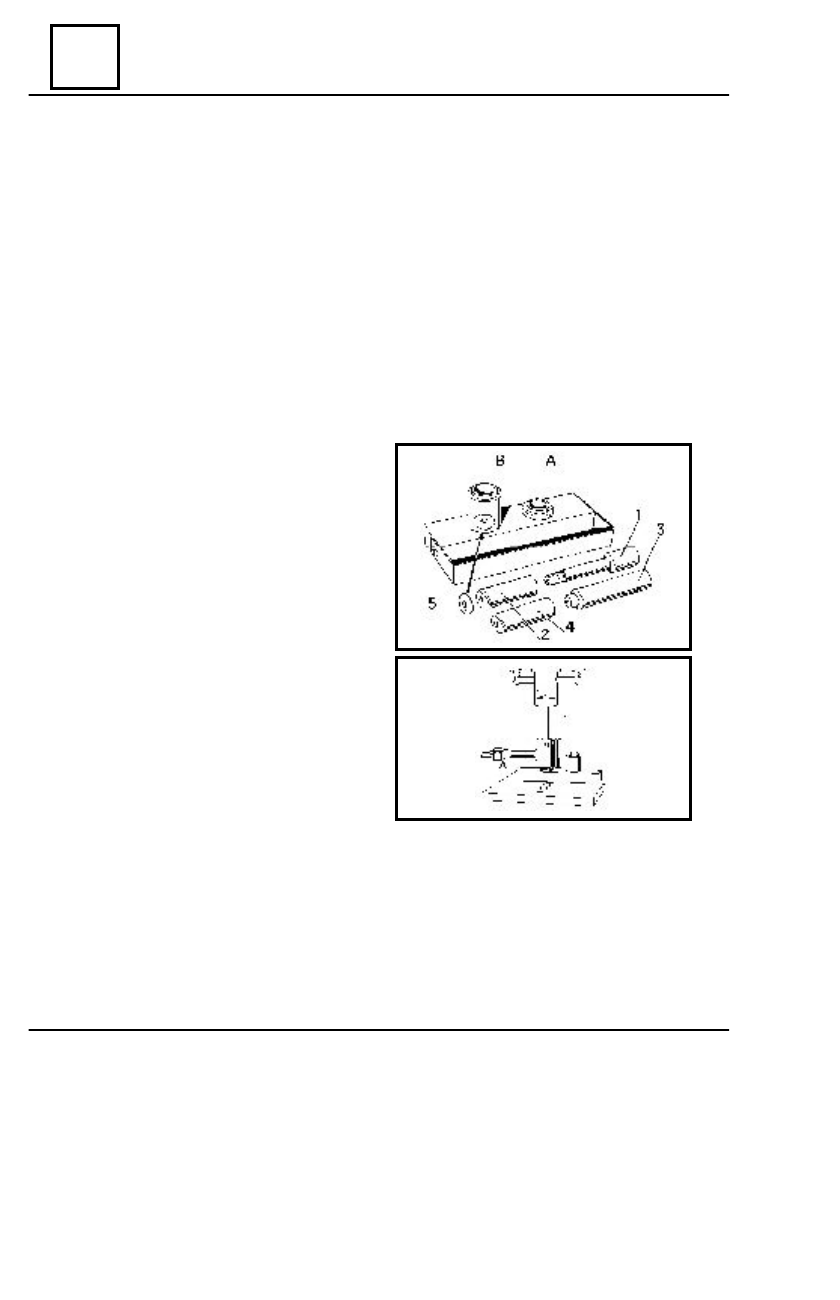

The dismounting and mounting of the piston

shafts is performed by means of the MOT 255

device ,made of:

- support bushing of the piston upon

dismounting the piston (A);

- support bushing of the piston upon

mounting (B);

- extractor mandrel (3);

- mounting mandrel (1);

- centering mandrel (2);

- connecting rod checking mandrel (4);

- washer (5).

Place the old piston with the blades item on

the support bushing (A).

Introduce the extractor mandrel (3) and by

means of a press, dismount the shaft of the old

piston.

CONNECTIONG RODS PREPARATION

Check:

- the state and the aspect of the connecting rods;

- the setting of the cap on the connecting rod body; remove the burrs if any in order to

ensure a correct setting;

- the parallelism of the head and the foot;

- the connecting rod twist.

DISMOUNTING - MOUNTING