Nissan Versa Note. Instruction - part 403

PREPARATION

EX-3

< PREPARATION >

C

D

E

F

G

H

I

J

K

L

M

A

EX

N

P

O

PREPARATION

PREPARATION

Special Service Tool

INFOID:0000000009405627

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service Tool

INFOID:0000000009405628

Tool number

(Kent-Moore No.)

Tool name

Description

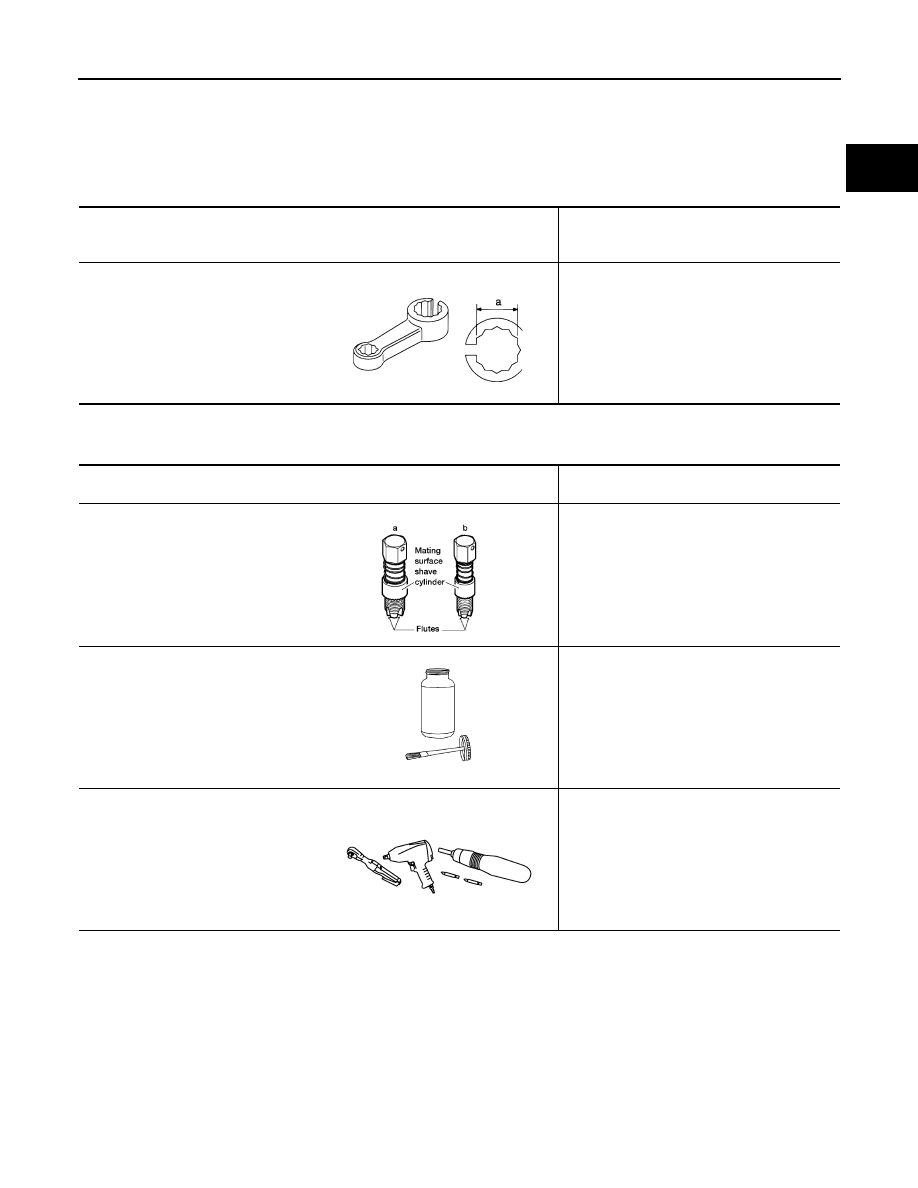

KV10114400

(J-38365-N1)

Heated oxygen sensor wrench

Loosening or tightening heated oxygen sen-

sors:

a: 22 mm (0.87 in)

S-NT636

(Kent-Moore No.)

Tool name

Description

(J-43897-18)

(J-43897-12)

Oxygen sensor thread cleaner

Reconditioning the exhaust system threads

before installing a new oxygen sensor (Use

with anti-seize lubricant shown below):

a: J-43897-18 (18 mm dia.) for zirconia ox-

ygen sensor

b: J-43897-12 (12 mm dia.) for titania oxy-

gen sensor

Anti-seize lubricant (Permatex 133AR

or equivalent meeting MIL specifica-

tion MIL-A-907)

Lubricating oxygen sensor thread cleaning

tool when reconditioning exhaust system

threads

Power tool

Loosening nuts, screws and bolts

AEM488

AEM489

PIIB1407E