Nissan Versa Note. Instruction - part 385

EM-56

< REMOVAL AND INSTALLATION >

[HR16DE]

TIMING CHAIN

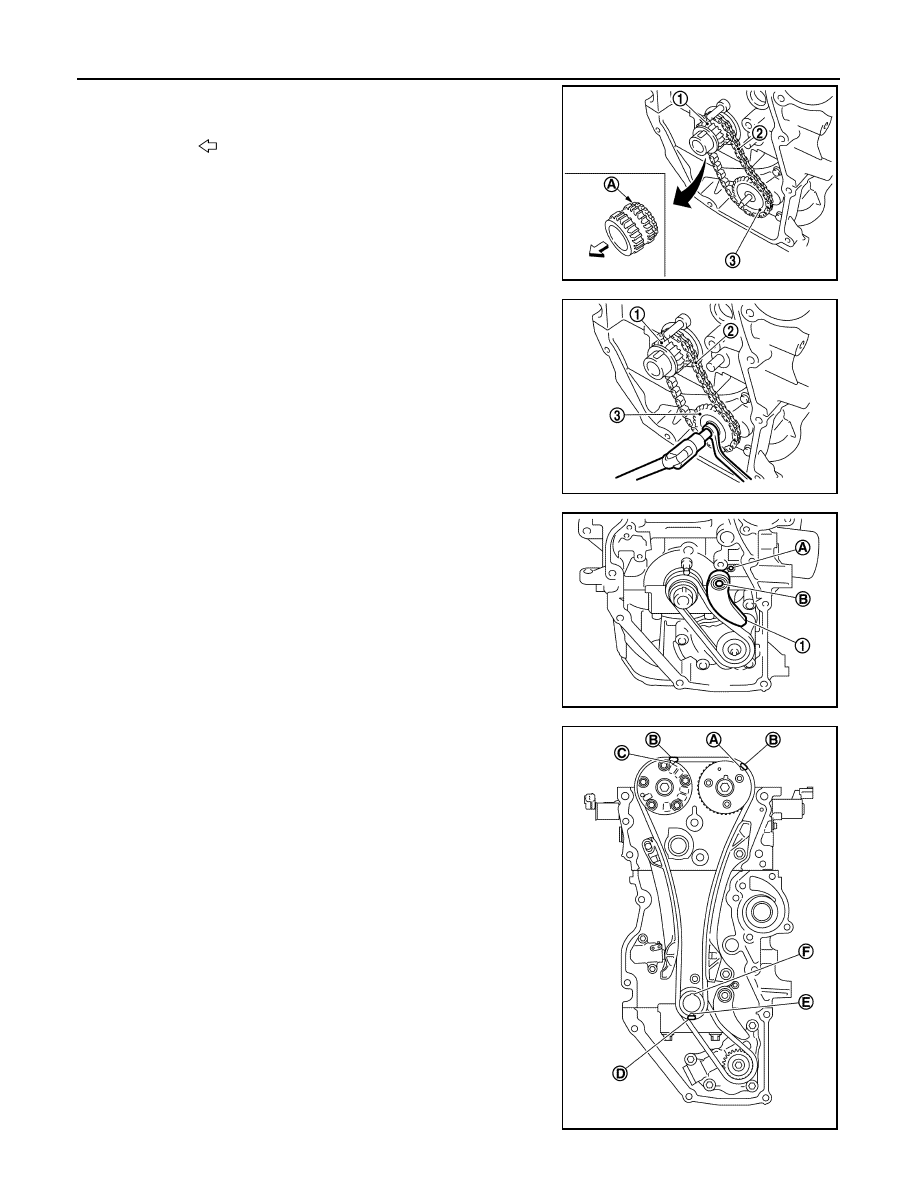

a. Install the crankshaft sprocket (1), the oil pump drive chain (2),

and the oil pump sprocket (3) at the same time.

• Install the crankshaft sprocket so that its invalid gear area (A)

is toward the back of the engine.

• Install the oil pump sprocket so that its protrusion faces the

front of engine.

NOTE:

There is no matching mark in the oil pump drive related parts.

b. Hold the top of the oil pump shaft using the socket (size: E8),

and then tighten the oil pump sprocket nut.

c.

Install oil pump drive chain tensioner (1).

• Insert the body into the shaft (B) while inserting the spring into

the attaching hole (A) of cylinder block front surface.

• Check that the tension is applied to the oil pump drive chain

after installing.

2. Install timing chain:

• Install by aligning matching marks on each sprocket and tim-

ing chain.

• If these matching marks are not aligned, rotate the camshaft

slightly to correct the position.

CAUTION:

• After the matching marks are aligned, keep them aligned

by holding them.

• To avoid skipped teeth, do not rotate crankshaft and cam-

shaft until front cover is installed.

: Engine front

JPBIA5248ZZ

(1) : Crankshaft sprocket

(2) : Oil pump drive chain

(3) : Oil pump sprocket

JPBIA4230ZZ

JPBIA4143ZZ

(A) : Matching mark (Peripheral groove)

(B) : Pink link

(C) : Matching mark (Peripheral groove)

(D) : Orange link

(E) : Matching mark (stamp)

(F) : Crankshaft key (point straight up)

JPBIA4144ZZ