Nissan Versa Sedan. Instruction - part 912

TRANSMITTER

WT-43

< REMOVAL AND INSTALLATION >

C

D

F

G

H

I

J

K

L

M

A

B

WT

N

O

P

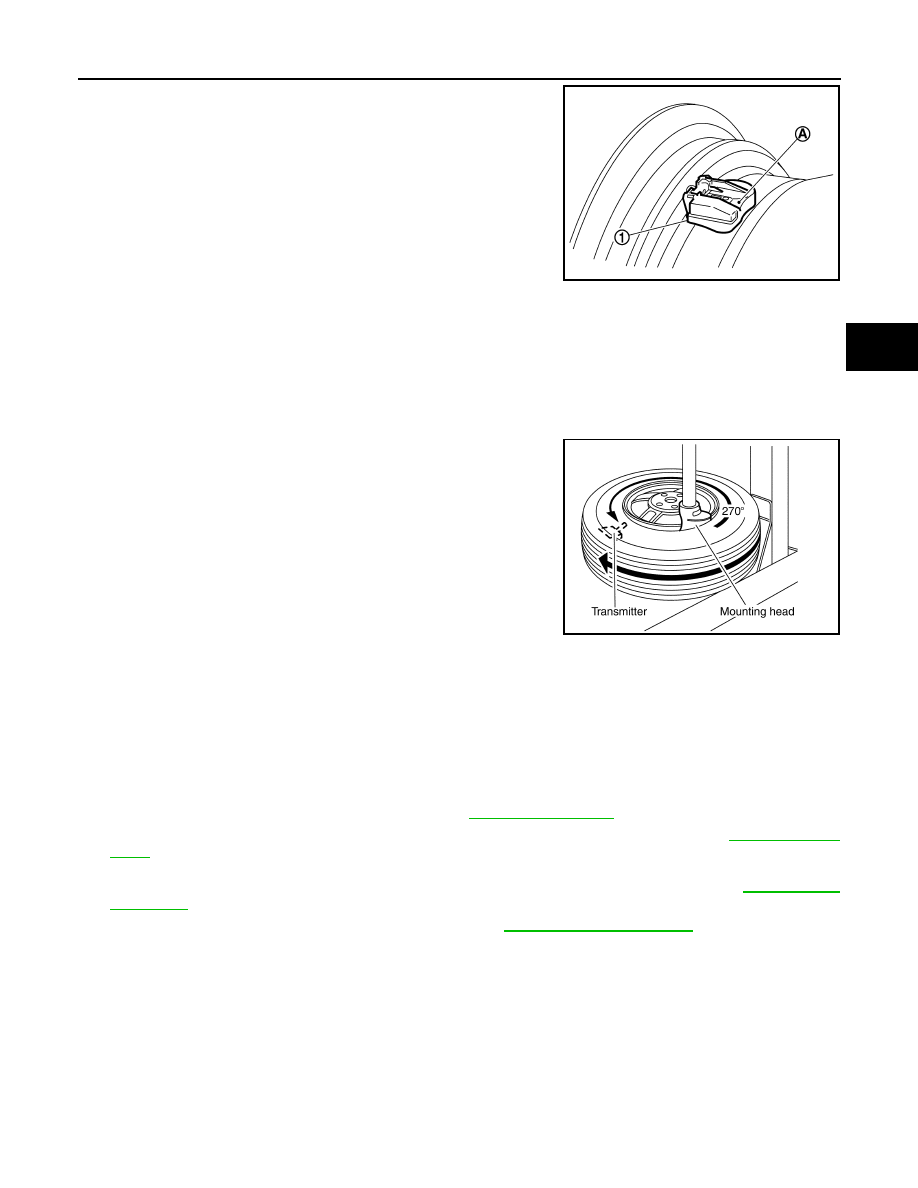

5. Install transmitter (1) to road wheel while pressing at position

(A).

CAUTION:

• Check that O-ring contacts horizontally with road wheel.

• Check that the base of the valve stem is positioned in the

groove of the metal plate.

6. Install and tighten the valve stem nut to the specified torque.

CAUTION:

Do not use power tool for installation.

7. Place wheel on turntable of tire machine. Ensure that transmitter

is 270 degrees from mounting/dismounting head.

NOTE:

Do not touch transmitter with mounting head.

8. Apply a suitable non-silicone lubricant to the tire outside bead.

CAUTION:

• Do not use silicone lubricant. Use of silicone lubricant will

deteriorate the tire and wheel.

• Do not allow lubricant to make contact with transmitter.

9. Install the tire outside bead onto the road wheel as normal.

NOTE:

If the tire is being reused, align the matching mark applied on

the tire with the position of the road wheel valve stem assembly for the purpose of road wheel and tire bal-

ance adjustment after installation. Ensure that the tire does not rotate relative to road wheel.

10. Install the valve core and inflate tire.

CAUTION:

Do not reuse valve core.

11. Install the valve cap.

CAUTION:

Do not reuse valve cap.

12. Balance the road wheel and tire assembly. Refer to

13. Install road wheel and tire assembly in appropriate wheel position on vehicle. Refer to

.

NOTE:

If replacing the transmitter, then transmitter wake up operation must be performed. Refer to

14. Adjust neutral position of steering angle sensor. Refer to

.

JSEIA0377ZZ

Valve stem nut

tightening torque

: 7.7 N·m (0.79 kg-m, 68 in-lb)

WEIA0046E