Nissan Versa Sedan. Instruction - part 863

TM-358

< DTC/CIRCUIT DIAGNOSIS >

[CVT: RE0F11A]

P0713 TRANSMISSION FLUID TEMPERATURE SENSOR A

P0713 TRANSMISSION FLUID TEMPERATURE SENSOR A

DTC Logic

INFOID:0000000009268160

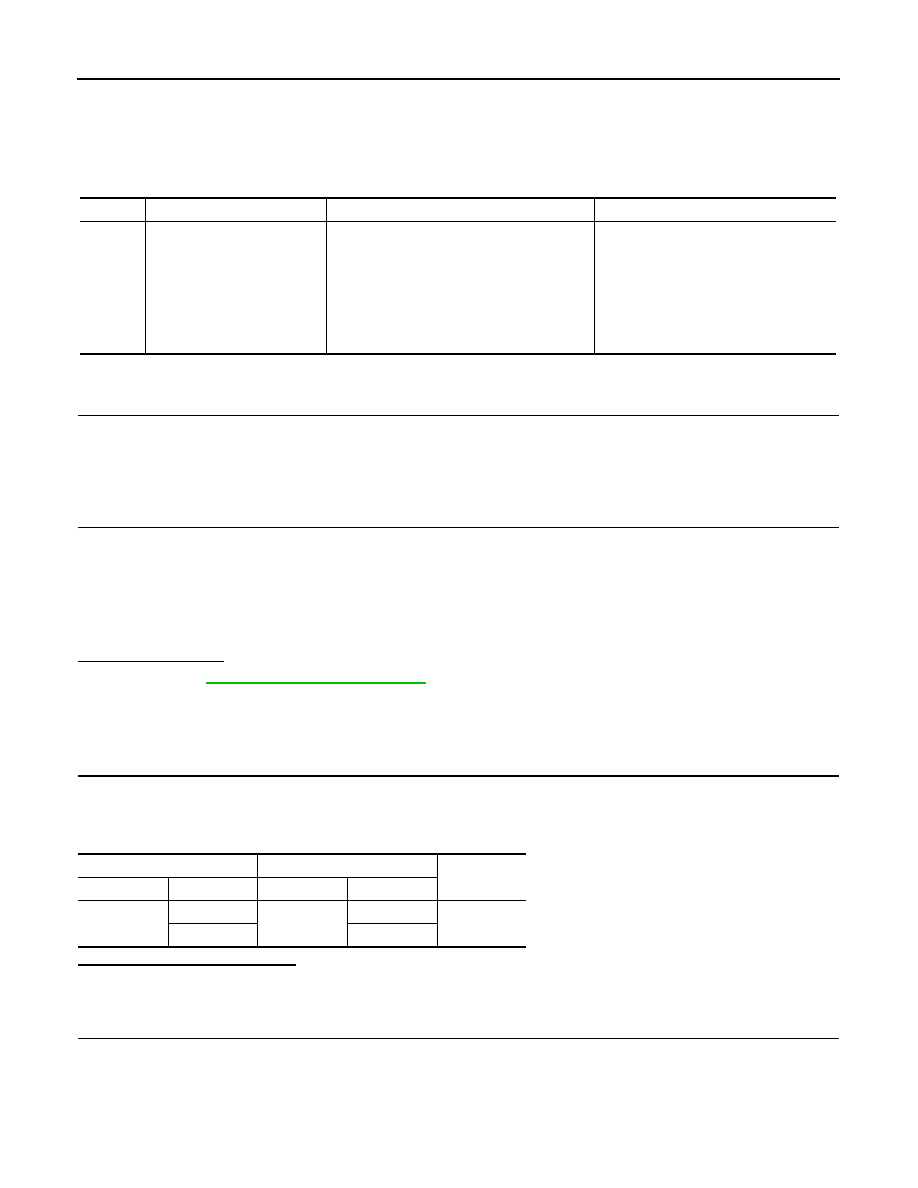

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition switch OFF and wait for at

least 10 seconds, then perform the next test.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

1. Start the engine.

2. Maintain the following condition for 10 seconds or more.

3. Stop the vehicle.

4. Check the first trip DTC.

Is “P0713” detected?

YES

>> Go to

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000009268161

1.

CHECK CIRCUIT BETWEEN TCM AND CVT UNIT (PART 1)

1. Turn ignition switch OFF.

2. Disconnect TCM connector and CVT unit connector.

3. Check continuity between TCM harness connector terminals and CVT unit harness connector terminals.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace malfunctioning part.

2.

CHECK CIRCUIT BETWEEN TCM AND CVT UNIT (PART 2)

1. Turn ignition switch ON.

2. Check voltage between TCM harness connector terminal and ground.

DTC

Trouble diagnosis name

DTC detection condition

Possible causes

P0713

Transmission Fluid Tempera-

ture Sensor A Circuit High

The CVT fluid temperature identified by the

TCM is

−40°C (−40°F) or less continuously for

5 seconds or more under the following diagno-

sis conditions:

• Diagnosis conditions

- Ignition switch: ON

- Vehicle speed: More than 10 km/h (7 MPH)

- TCM power supply voltage: More than 11 V

• Harness or connector

(CVT fluid temperature sensor circuit is

open or shorted to power supply)

• CVT fluid temperature sensor

Vehicle speed

: 20 km/h (12 MPH) or more

TCM

CVT unit

Continuity

Connector

Terminal

Connector

Terminal

F44

12

F46

4

Existed

11

25