Nissan Versa Sedan. Instruction - part 617

PCS-54

< DTC/CIRCUIT DIAGNOSIS >

[IPDM E/R (WITHOUT I-KEY)]

B2099 IGNITION RELAY OFF STUCK

B2099 IGNITION RELAY OFF STUCK

Description

INFOID:0000000009266447

The ignition relay integrated in IPDM E/R is operated with ignition switch ON signal from the ignition switch.

DTC Logic

INFOID:0000000009266448

DTC DETECTION LOGIC

Diagnosis Procedure

INFOID:0000000009266449

1.

PERFORM SELF DIAGNOSTIC RESULT

1. Turn the ignition switch ON.

2. Erase “SELF-DIAG RESULTS” of IPDM E/R.

3. Turn ignition switch OFF, and wait for 1 second or more.

4. Turn the ignition switch ON. Check “SELF-DIAG RESULTS” again.

Is “IGN RELAY ON” displayed?

YES

>> Replace IPDM E/R. Refer to

PCS-56, "Removal and Installation"

NO

>> Refer to

GI-45, "Intermittent Incident"

.

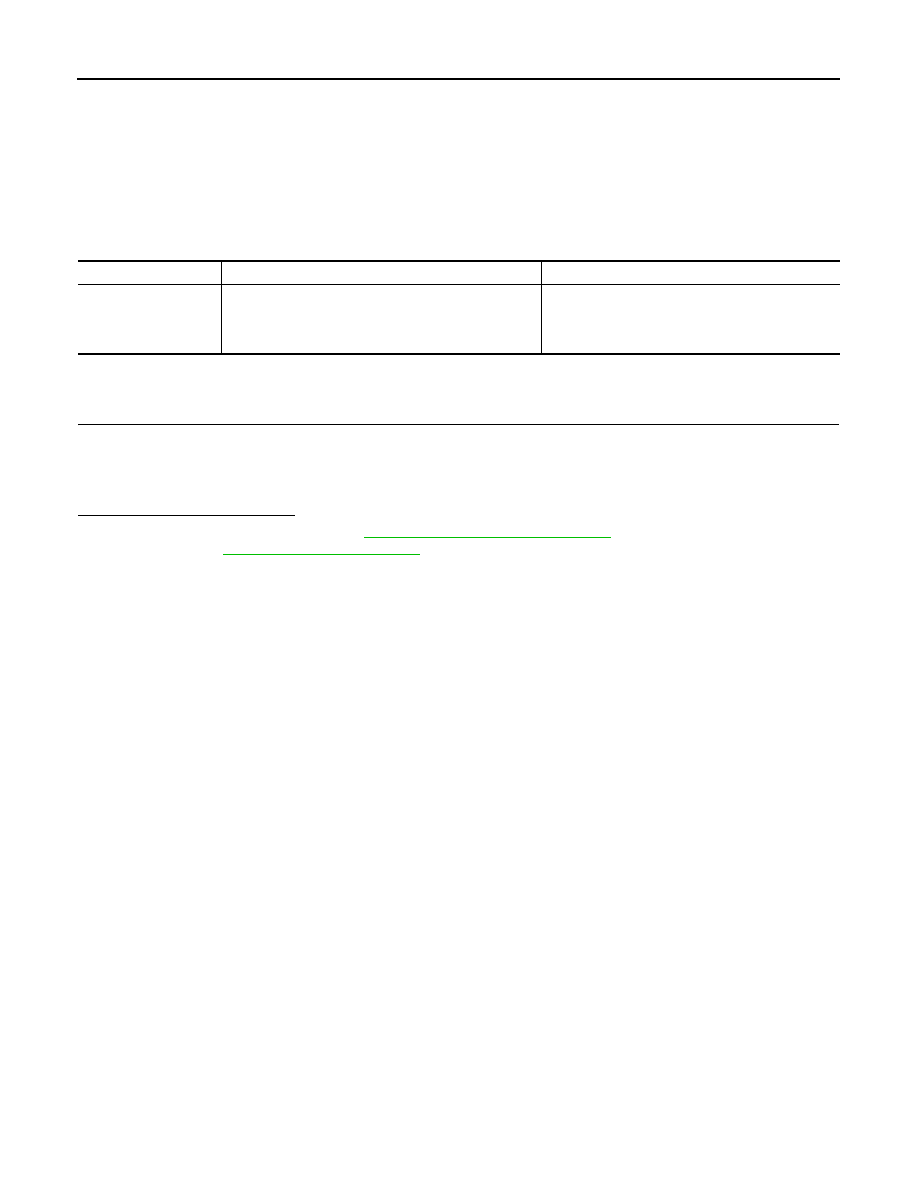

CONSULT Display

DTC Detection Condition

Possible Cause

IGN RELAY ON

[B2098]

The ignition relay ON is detected for 1 second at ignition

switch OFF

(CPU monitors the status at the contact and excitation

coil circuits of the ignition relay inside it)

Ignition relay malfunction