Nissan Versa Sedan. Instruction - part 564

MA-14

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE

ENGINE MAINTENANCE

DRIVE BELT

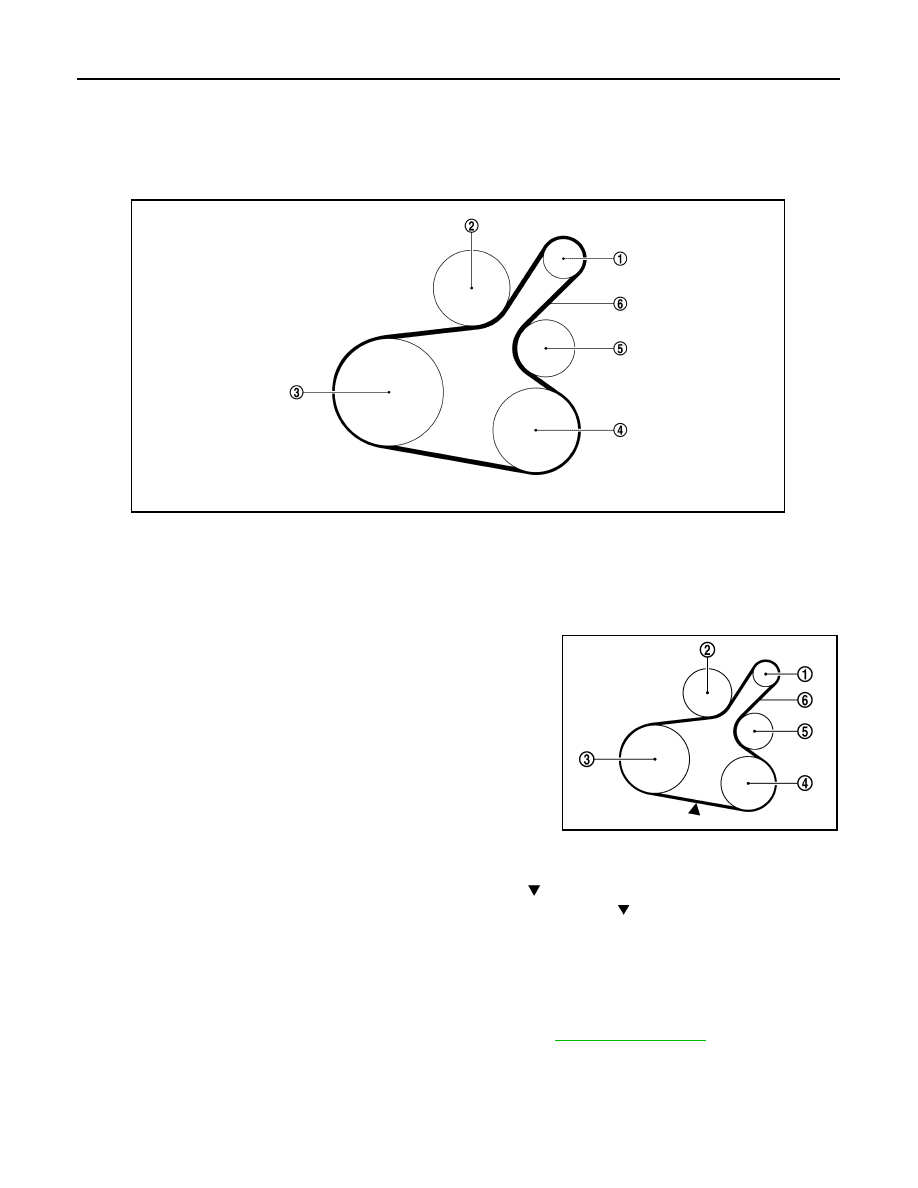

DRIVE BELT : Exploded View

INFOID:0000000009269041

DRIVE BELT : Inspection

INFOID:0000000009269042

• Inspection should be done only when engine is cold or over 30

minutes after the engine is stopped.

• Visually check belt for wear, damage, and cracks on inside and

edges.

• Turn crankshaft pulley clockwise twice, and check that the tension on all pulleys equalizes before testing.

• When measuring deflection, apply 98.1 N (10 kg, 22 lb) at the ( ) marked point.

• Measure the belt tension and frequency with acoustic tension gauge at the ( ) marked point.

CAUTION:

• When the tension and frequency are measured, the acoustic tension gauge should be used.

• When checking immediately after installation, first adjust it to the specified value. Then, after turning

crankshaft two turns or more, readjust to the specified value to avoid variation in deflection between

pulleys.

1.

Generator

2.

Water pump

3.

Crankshaft pulley

4.

A/C compressor (with A/C models)

Idler pulley (without A/C models)

5.

Idler pulley

6.

Drive belt

JSBIA1053ZZ

(1)

: Generator

(2)

: Water pump

(3)

: Crankshaft pulley

(4)

: A/C compressor (with A/C models)

: Idler pulley (without A/C models)

(5)

: Idler pulley

(6)

: Drive belt

Belt deflection/belt tension and frequency

: Refer to

.

PBIC3642E