Nissan Versa Sedan. Instruction - part 483

CONDENSER

HA-31

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

CONDENSER

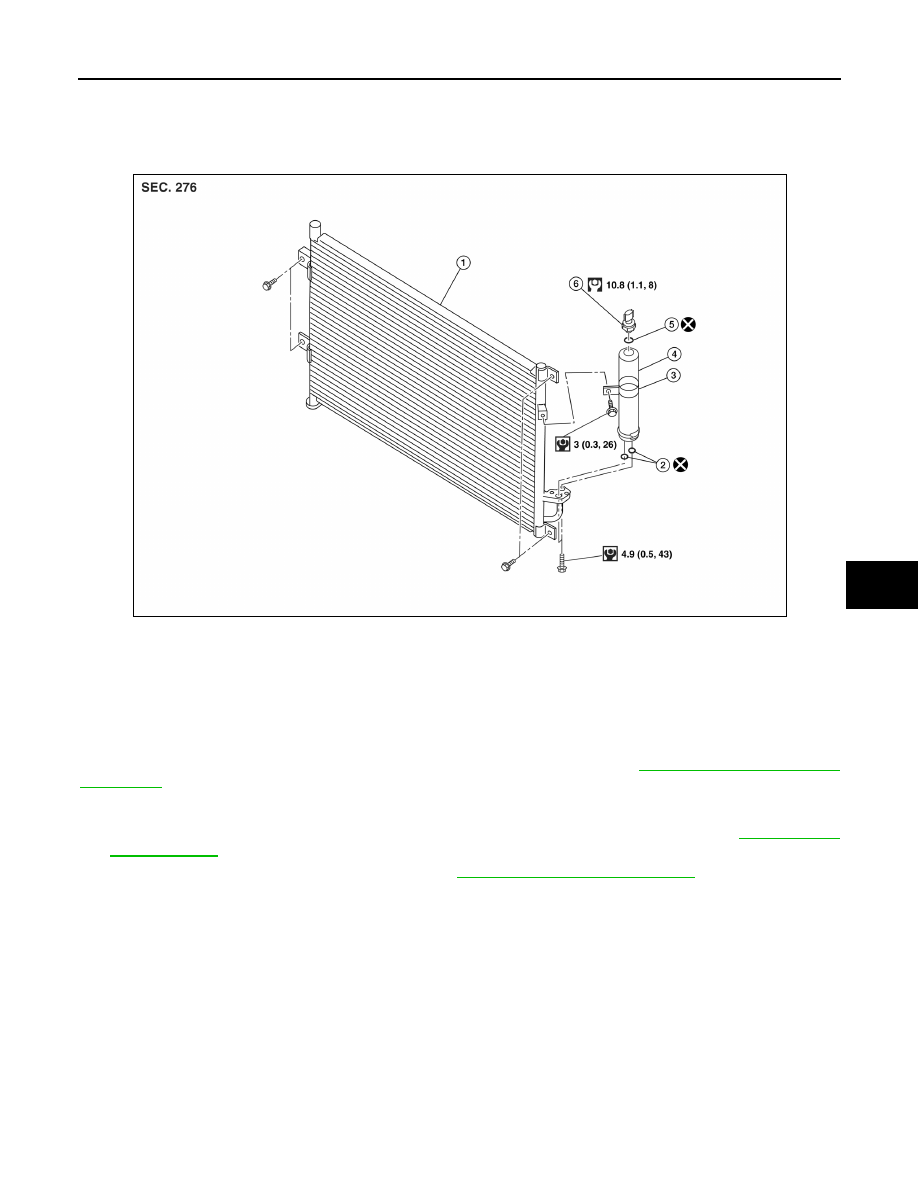

Exploded View

INFOID:0000000009269754

Removal and Installation

INFOID:0000000009269755

CAUTION:

Perform oil return operation before each refrigeration system disassembly. However, if a large amount

of refrigerant or oil is detected do not perform oil return operation. Refer to

REMOVAL

1. Use refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant. Refer to

2. Remove the radiator core upper support. Refer to

CO-14, "Removal and Installation"

.

3. Remove high-pressure flexible hose bolt and disconnect high-pressure flexible hose from the condenser.

CAUTION:

Cap or wrap the joint of the A/C piping and condenser with suitable material such as vinyl tape to

avoid the entry of air.

4. Remove high-pressure flexible hose bolt and disconnect high-pressure pipe from the condenser.

CAUTION:

Cap or wrap the joint of the A/C piping and condenser with suitable material such as vinyl tape to

avoid the entry of air.

5. Remove the condenser and liquid tank assembly.

CAUTION:

Be careful not to damage core surface of condenser.

INSTALLATION

Installation is in the reverse order of removal.

1.

Condenser

2.

O-rings

3.

Liquid tank bracket

4.

Liquid tank

5.

O-ring

6.

Refrigerant pressure sensor

AWIIA1612ZZ