Nissan Versa Sedan. Instruction - part 462

GI-30

< VEHICLE INFORMATION >

IDENTIFICATION INFORMATION

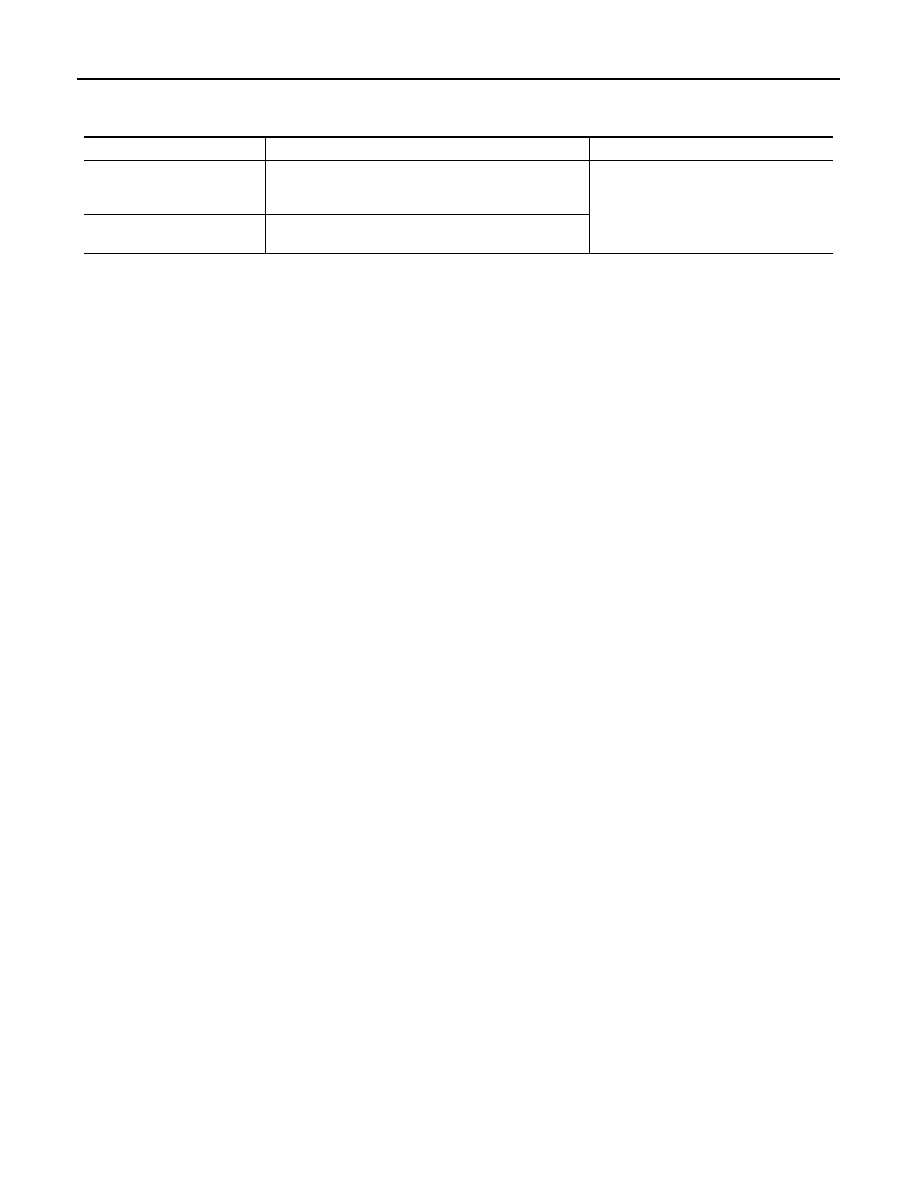

Wheels & Tires

INFOID:0000000009266887

Conventional

Spare

Road wheel/offset mm (in)

15 X 5.5J Steel/40 (1.57)

15 X 5.5J Aluminum/40 (1.57)

16 X 6.0J Aluminum/45 (1.77)

T125/70D15

Tire size

P185/65R15

P195/55R16