Nissan Versa Sedan. Instruction - part 450

FSU-8

< REMOVAL AND INSTALLATION >

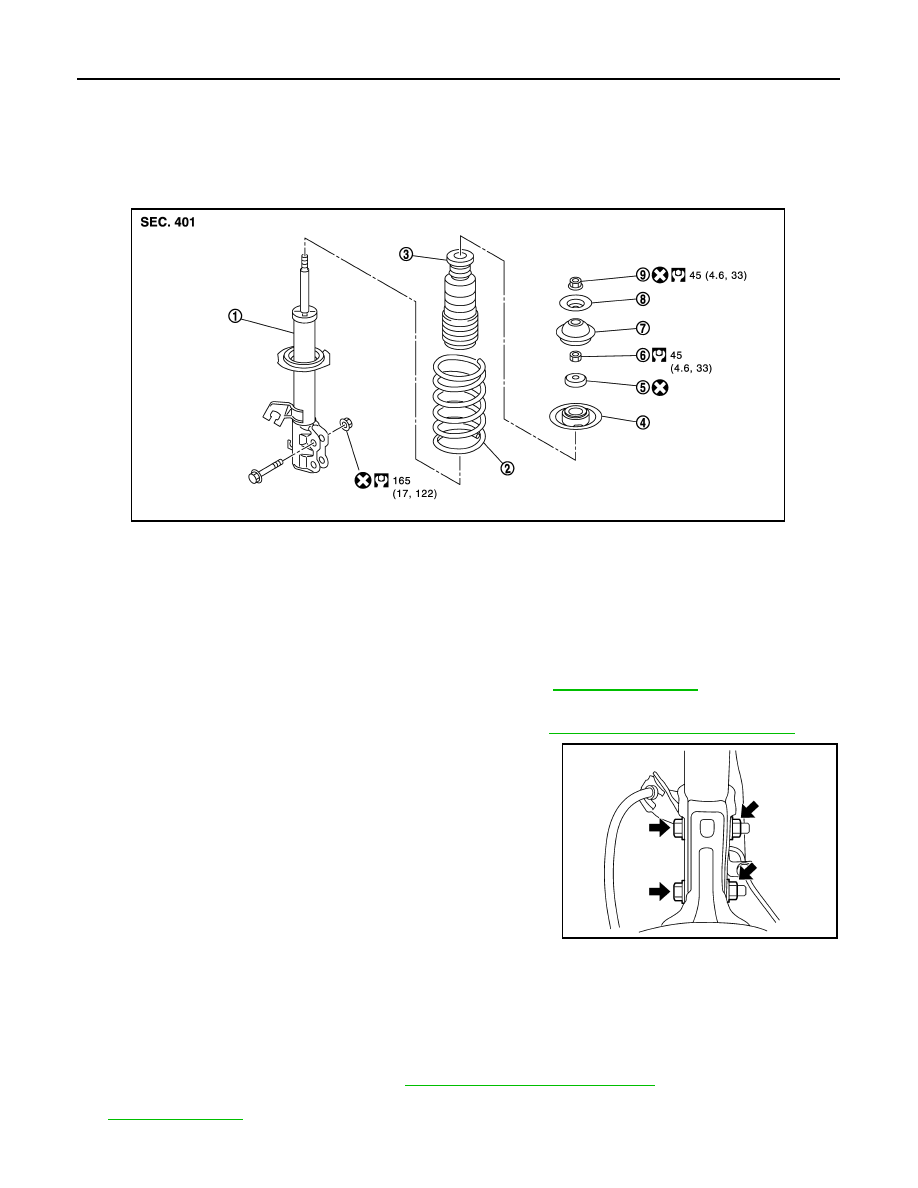

FRONT COIL SPRING AND STRUT

REMOVAL AND INSTALLATION

FRONT COIL SPRING AND STRUT

Exploded View

INFOID:0000000009267400

Removal and Installation

INFOID:0000000009267401

REMOVAL

1. Remove the wheel and tire assembly using power tool. Refer to

2. Remove brake hose lock plate from strut assembly.

3. Remove stabilizer connecting rod from strut assembly. Refer to

FSU-14, "Removal and Installation"

4. Remove strut bolts and nuts from steering knuckle.

5. Remove stopper insulator lock nut and stopper insulator.

6. Remove strut assembly.

INSTALLATION

Installation is in the reverse order of removal.

• Secure the head of strut piston rod to keep it from rotating, then tighten the stopper insulator lock nut to the

specified torque.

CAUTION:

Do not reuse stopper insulator lock nut.

• Do not reuse the nuts that secure the strut to the steering knuckle and stopper insulator lock nut.

• Perform inspection after installation. Refer to

FSU-6, "Inspection and Adjustment"

• After replacing the strut assembly, always follow the disposal procedure to discard the strut assembly. Refer

1.

Strut assembly

2.

Coil spring

3.

Bound bumper

4.

Spring upper seat

5.

Strut mounting bearing

6.

Piston rod lock nut

7.

Strut mounting insulator

8.

Stopper insulator

9.

Stopper insulator lock nut

JPEIA0261GB

WEIA0179E