Nissan Versa Sedan. Instruction - part 419

POWER SUPPLY AND GROUND CIRCUIT

EXL-77

< DTC/CIRCUIT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

M

A

B

EXL

N

O

P

Is the fuse blown?

YES

>> Replace the blown fuse or fusible link after repairing the affected circuit.

NO

>> GO TO 2

2.

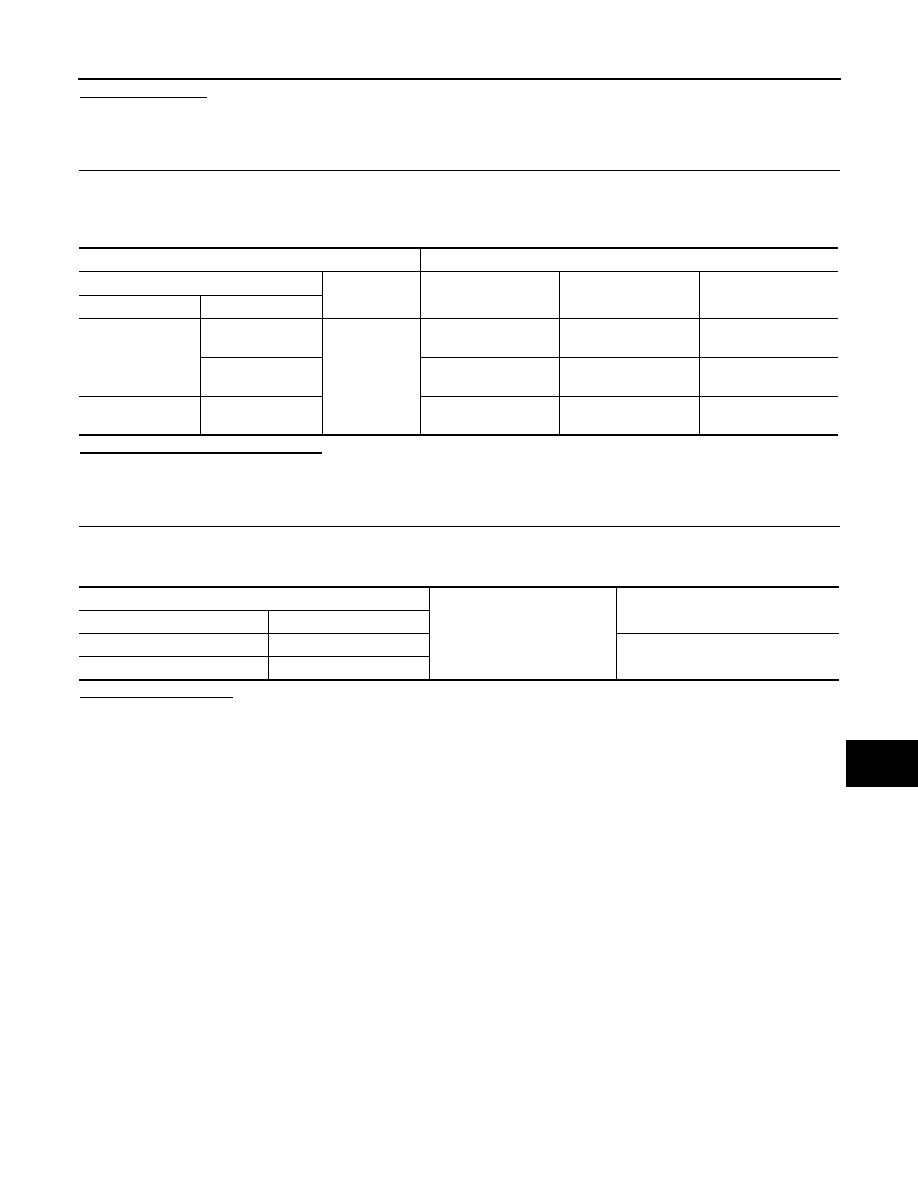

CHECK BATTERY POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R.

3. Check voltage between IPDM E/R connectors and ground.

Is the measurement value normal?

YES

>> GO TO 3

NO

>> Repair or replace harness.

3.

CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between IPDM E/R connectors and ground.

Does continuity exist?

YES

>> Inspection End.

NO

>> Repair or replace harness.

Terminals

Ignition switch position

(+)

(

−)

OFF

ON

START

Connector

Terminal

E42

1

Ground

Battery

voltage

Battery

voltage

Battery

voltage

2

Battery

voltage

Battery

voltage

Battery

voltage

E44

10

0V

Battery

voltage

Battery

voltage

IPDM E/R

Ground

Continuity

Connector

Terminal

E45

19

Yes

E46

60