Nissan Versa Sedan. Instruction - part 398

SERVICE DATA AND SPECIFICATIONS (SDS)

EM-127

< SERVICE DATA AND SPECIFICATIONS (SDS)

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

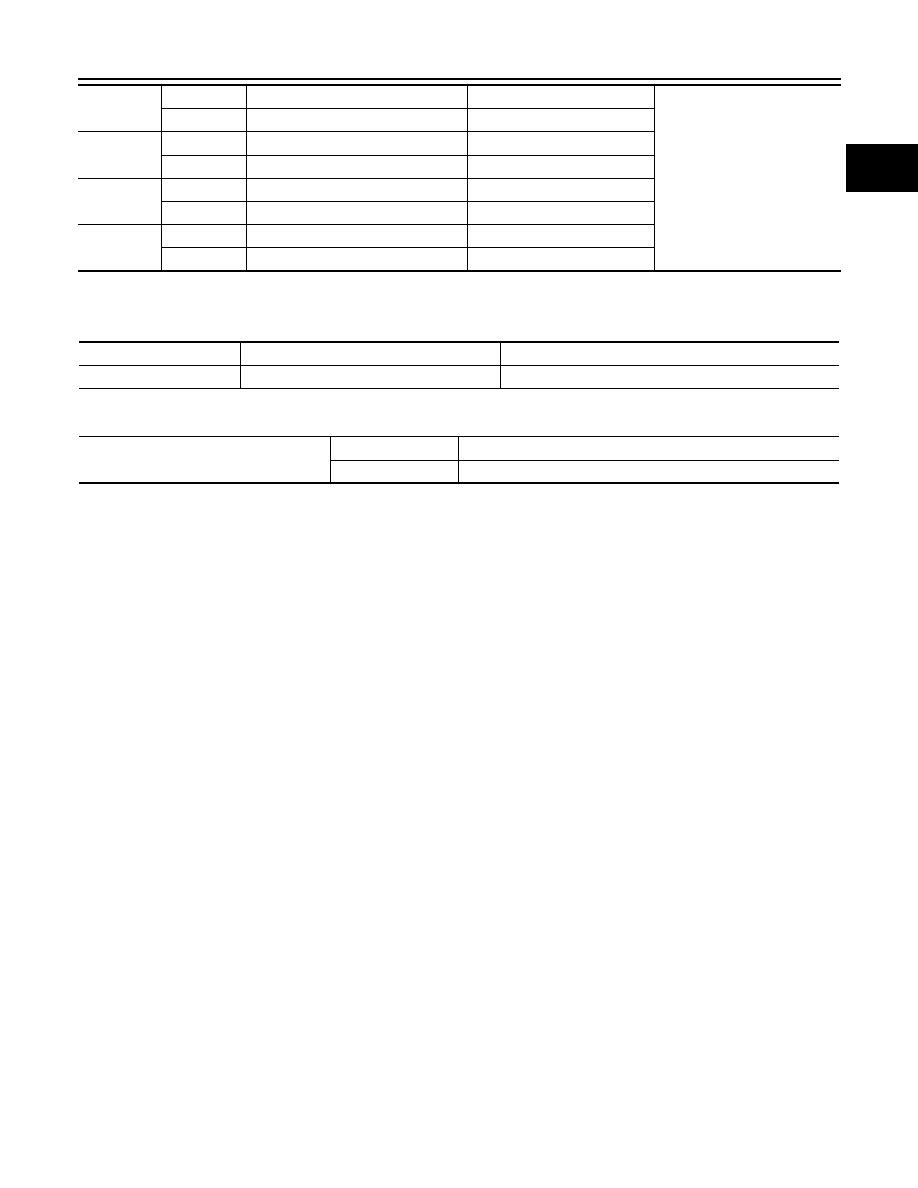

*: Always check with the Parts Department for the latest parts information.

Undersize

Unit: mm (in)

Bearing Oil Clearance

Unit: mm (in)

12

UPR

1.501 - 1.504 (0.0591 - 0.0592)

Brown

Grade and color are different

between upper and lower bear-

ings.

LWR

1.504 - 1.507 (0.0592 - 0.0593)

Green

23

UPR

1.504 - 1.507 (0.0592 - 0.0593)

Green

LWR

1.507 - 1.510 (0.0593 - 0.0594)

Yellow

34

UPR

1.507 - 1.510 (0.0593 - 0.0594)

Yellow

LWR

1.510 - 1.513 (0.0594 - 0.0596)

Blue

56

UPR

1.513 - 1.516 (0.0596 - 0.0597)

Pink

LWR

1.516 - 1.519 (0.0597 - 0.0598)

Purple

Items

Thickness

Crankshaft pin journal diameter

US 0.25 (0.0098)

1.627 - 1.635 (0.0640 - 0.0644)

Grind so that bearing clearance is the specified value.

Connecting rod bearing oil clearance

Standard

0.020 - 0.030 (0.0008 - 0.0012)

Limit

0.10 (0.0039)