Nissan Versa Sedan. Instruction - part 318

P0327, P0328 KS

EC-271

< DTC/CIRCUIT DIAGNOSIS >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

2. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.

CHECK KNOCK SENSOR

EC-271, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Replace knock sensor. Refer to

.

5.

CHECK INTERMITTENT INCIDENT

GI-45, "Intermittent Incident"

.

>> INSPECTION END

Component Inspection

INFOID:0000000009267155

1.

CHECK KNOCK SENSOR

1. Turn ignition switch OFF.

2. Disconnect knock sensor harness connector.

3. Check resistance between knock sensor terminals as follows.

NOTE:

It is necessary to use an ohmmeter which can measure more than 10 M

Ω.

CAUTION:

Do not use any knock sensors that have been dropped or physically damaged. Use only new ones.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace knock sensor. Refer to

.

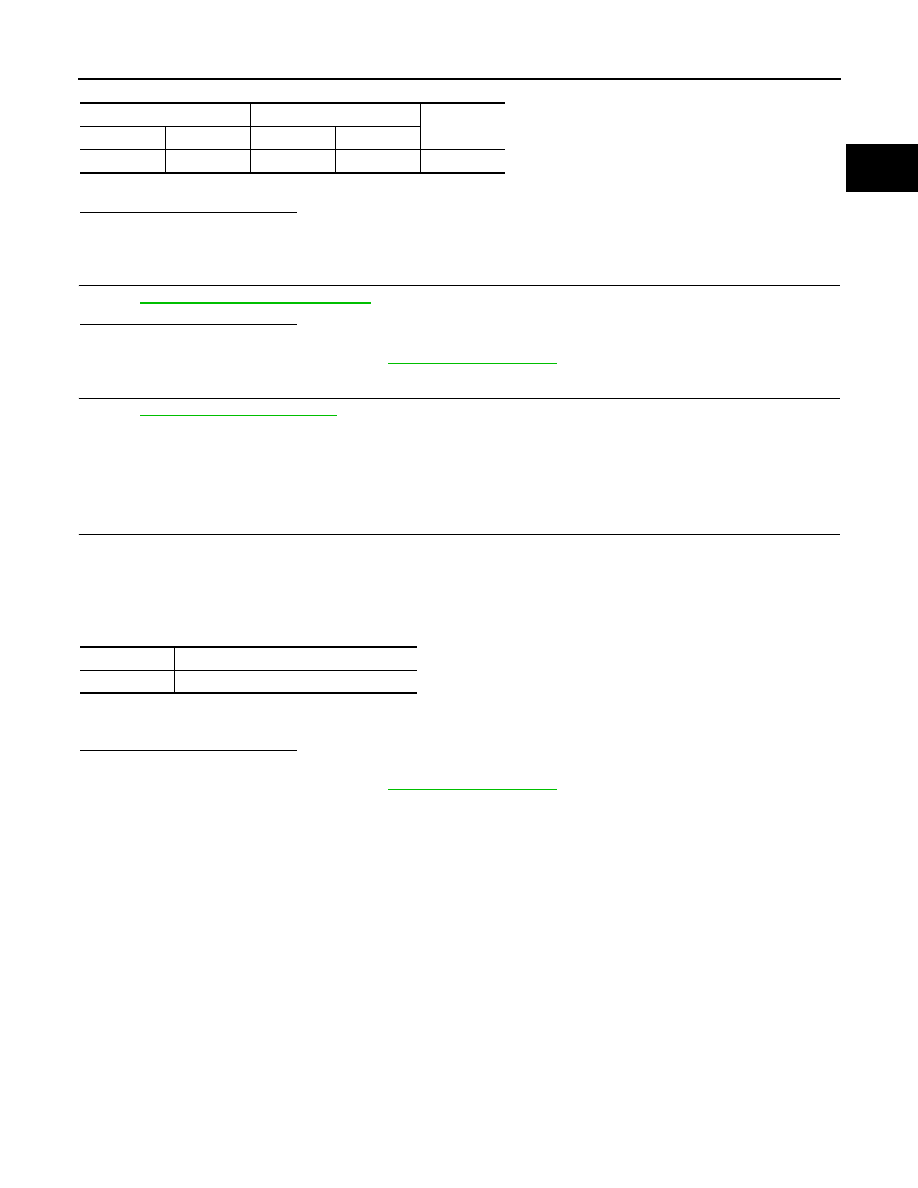

Knock sensor

ECM

Continuity

Connector

Terminal

Connector

Terminal

F14

1

F11

37

Existed

Terminals

Resistance [at 20

°C (68°F)]

1 and 2

Approx. 532 - 588 k

Ω