Nissan Versa Sedan. Instruction - part 310

P014C, P014D, P015A, P015B, A/F SENSOR 1

EC-239

< DTC/CIRCUIT DIAGNOSIS >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

NO

>> GO TO 7.

7.

DETECT MALFUNCTIONING PART

Check the following.

• IPDM E/R harness connector F42

• Harness for open or short between A/F sensor 1 and fuse

>> Repair or replace harness or connectors.

8.

CHECK A/F SENSOR 1 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between A/F sensor 1 harness connector and ECM harness connector.

4. Check the continuity between A/F sensor 1 harness connector and ground, or ECM harness connector

and ground.

5. Also check harness for short to power.

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

9.

CHECK AIR FUEL RATIO (A/F) SENSOR 1 HEATER

EC-168, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 10.

NO

>> GO TO 13.

10.

CHECK MASS AIR FLOW SENSOR

EC-180, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 11.

NO

>> Replace mass air flow sensor. Refer to

EM-25, "Removal and Installation"

.

11.

CHECK PCV VALVE

.

Is the inspection result normal?

YES

>> GO TO 12.

NO

>> Repair or replace PCV valve. Refer to

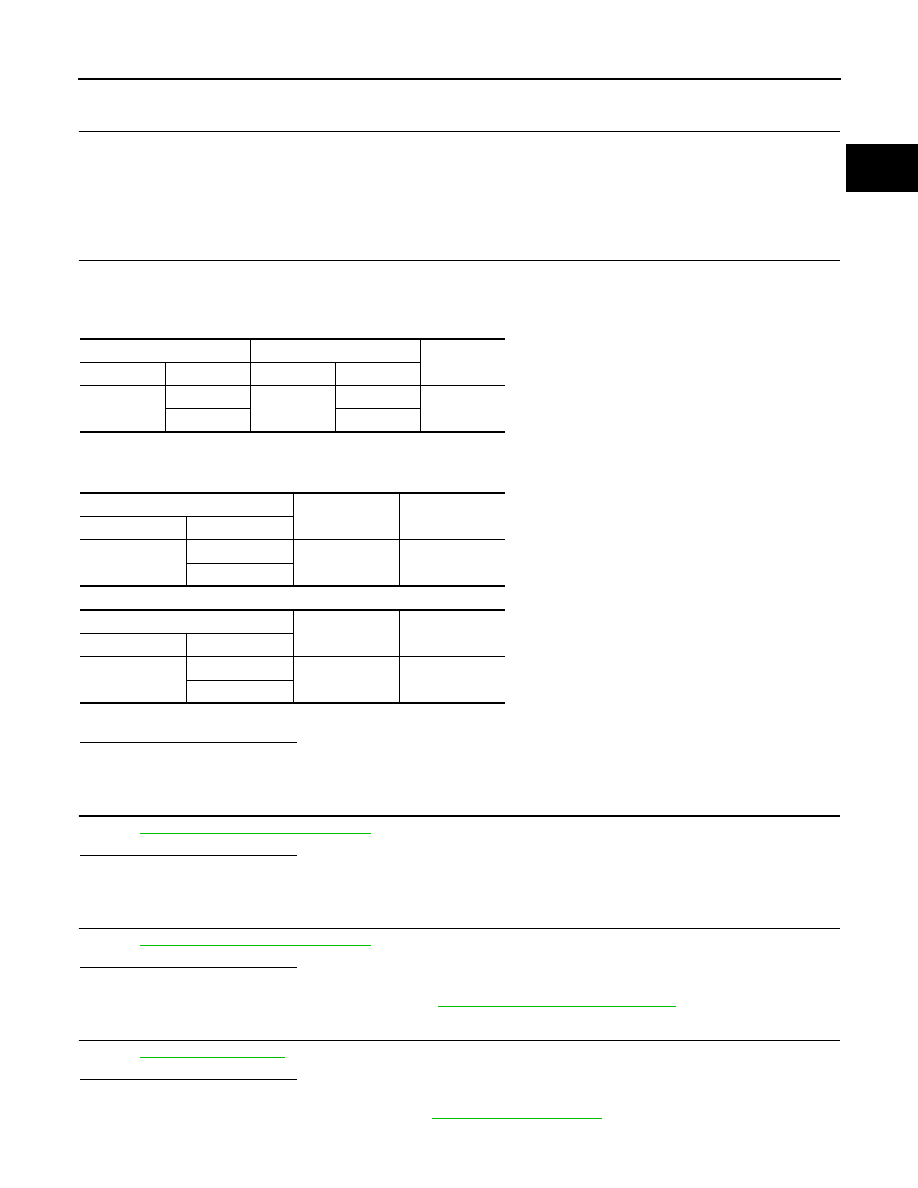

A/F sensor 1

ECM

Continuity

Connector

Terminal

Connector

Terminal

F12

1

F11

49

Existed

2

53

A/F sensor 1

Ground

Continuity

Connector

Terminal

F12

1

Ground

Not existed

2

ECM

Ground

Continuity

Connector

Terminal

F11

49

Ground

Not existed

53