Nissan Versa Sedan. Instruction - part 253

PRECAUTIONS

EC-11

< PRECAUTION >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

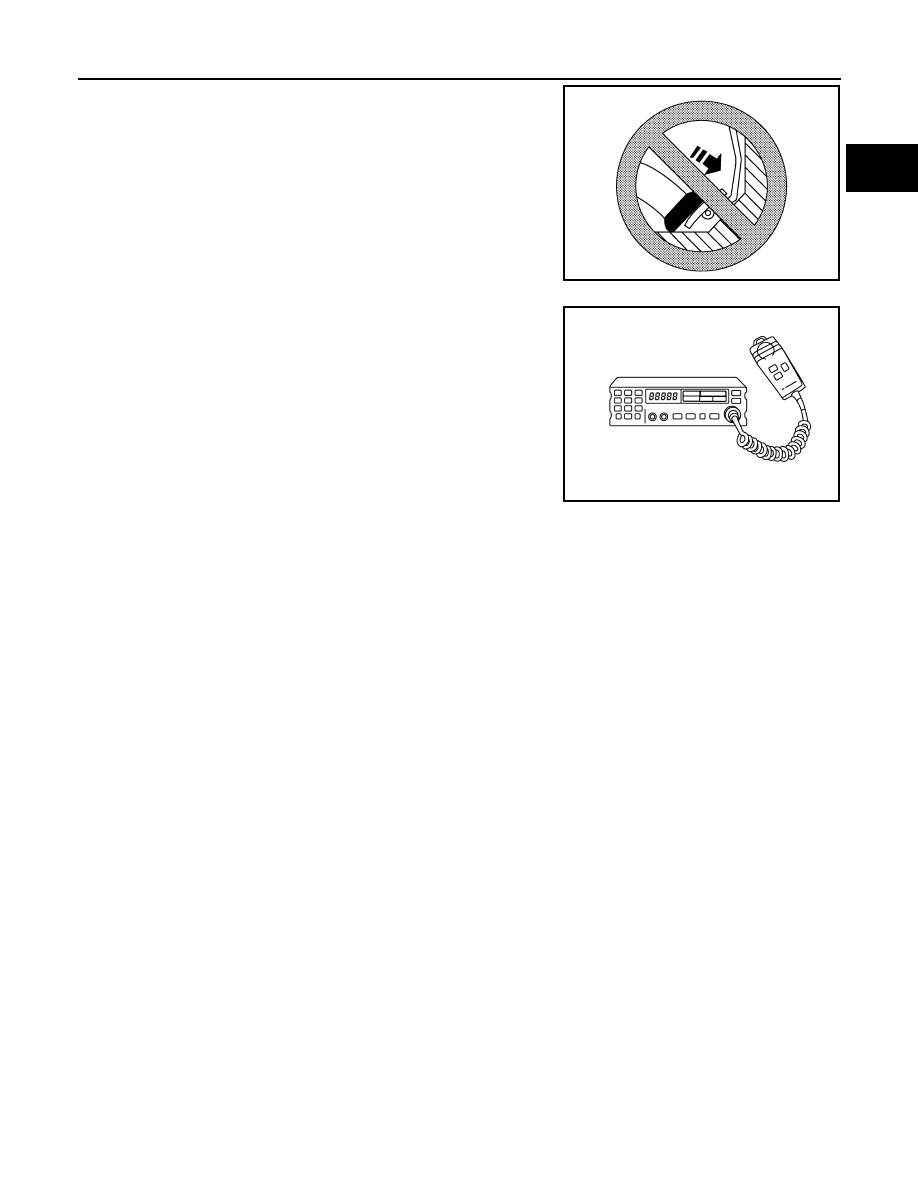

• Do not depress accelerator pedal when starting.

• Immediately after starting, do not rev up engine unnecessar-

ily.

• Do not rev up engine just prior to shutdown.

• When installing C.B. ham radio or a mobile phone, be sure to

observe the following as it may adversely affect electronic

control systems depending on installation location.

- Keep the antenna as far as possible from the electronic con-

trol units.

- Keep the antenna feeder line more than 20 cm (8 in) away

from the harness of electronic controls.

Do not let them run parallel for a long distance.

- Adjust the antenna and feeder line so that the standing-wave

ratio can be kept smaller.

- Be sure to ground the radio to vehicle body.

SEF709Y

SEF708Y