Nissan Altima HL32 Hybrid. Instruction - part 978

SE-14

< SYMPTOM DIAGNOSIS >

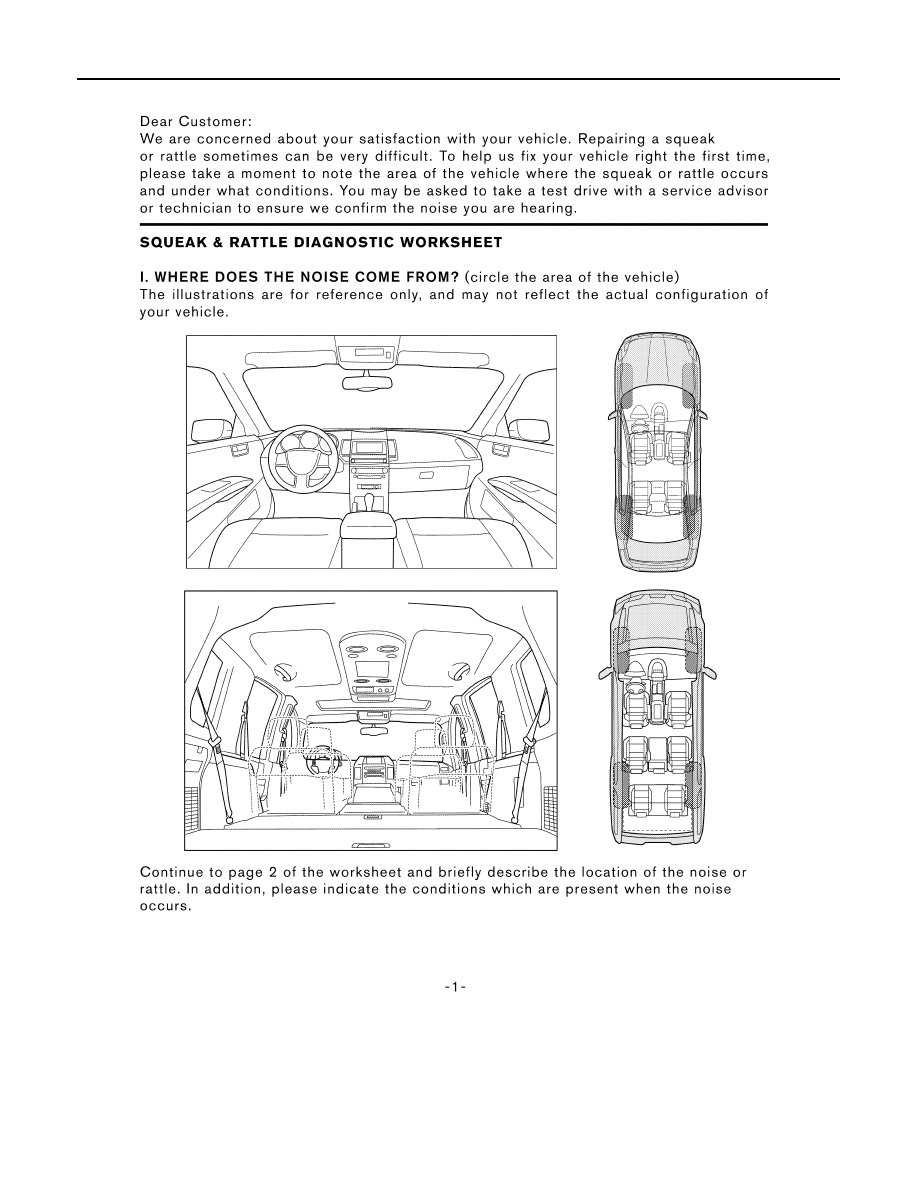

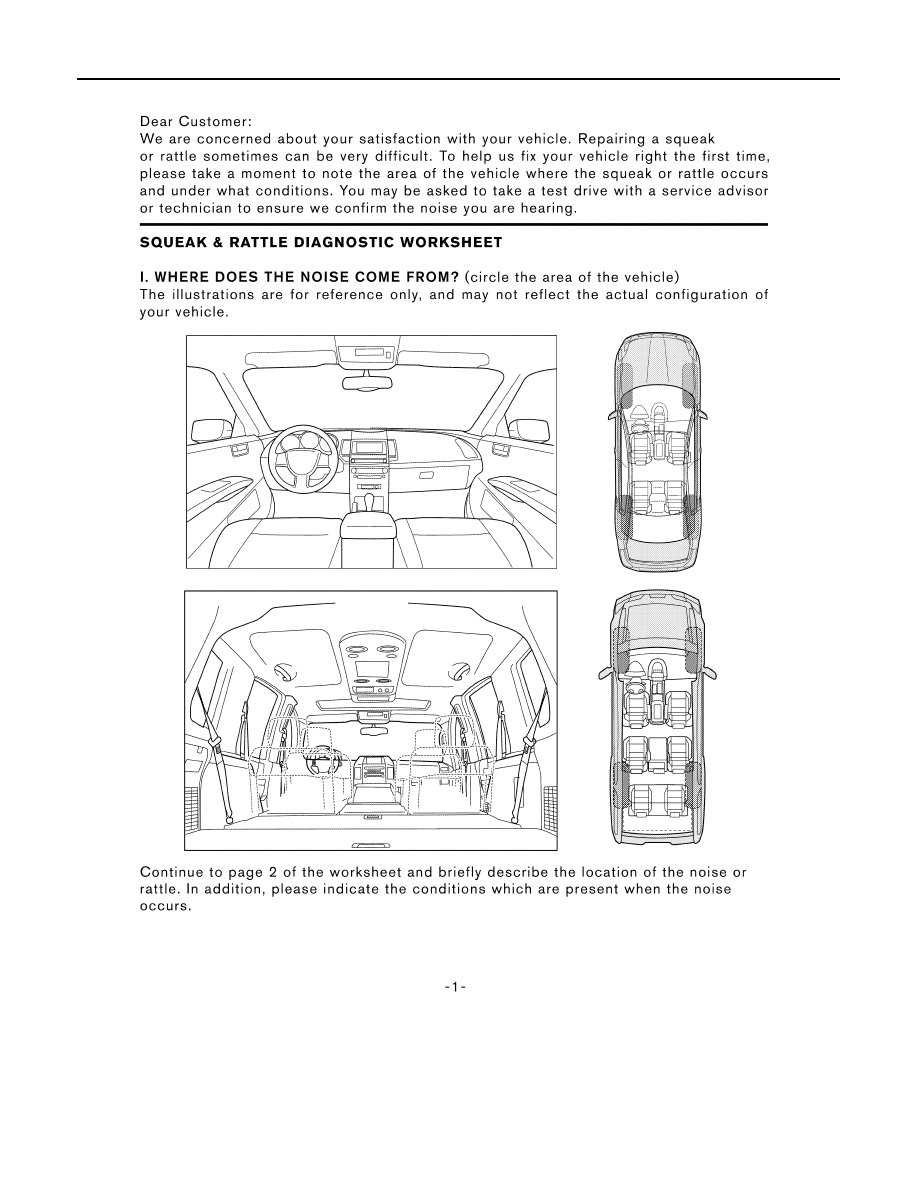

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Diagnostic Worksheet

INFOID:0000000004215450

LAIA0072E

|

|

|

SE-14 < SYMPTOM DIAGNOSIS > SQUEAK AND RATTLE TROUBLE DIAGNOSES Diagnostic Worksheet INFOID:0000000004215450 LAIA0072E |