Nissan Altima HL32 Hybrid. Instruction - part 452

FRONT DRIVE SHAFT

FAX-13

< ON-VEHICLE REPAIR >

C

E

F

G

H

I

J

K

L

M

A

B

FAX

N

O

P

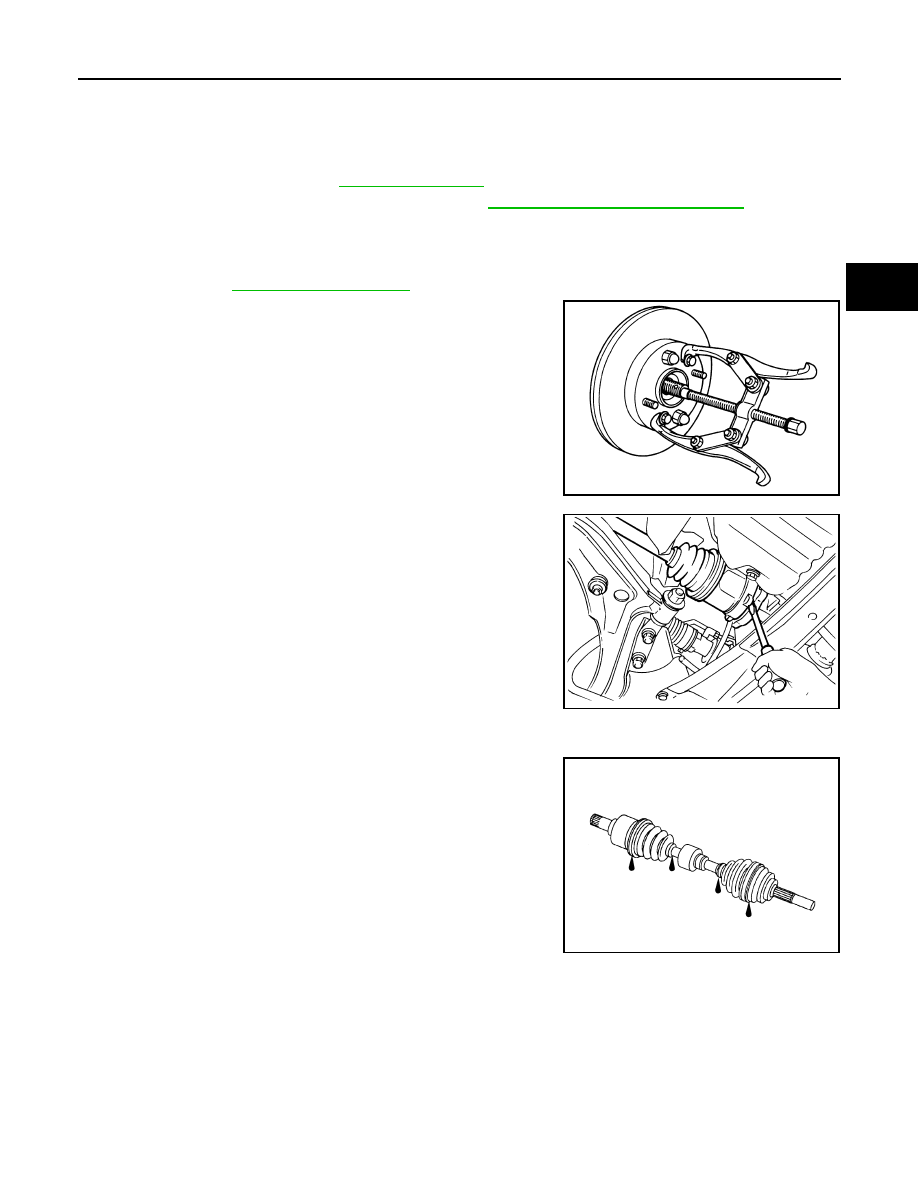

REMOVAL

1. Remove wheel and tire. Refer to

.

2. Remove wheel sensor from steering knuckle. Refer to

BRC-202, "Removal and Installation"

3. Remove cotter pin. Then remove lock nut from drive shaft using power tool.

4. Remove brake hose lock plate. Then remove brake hose from strut.

5. Remove the lower ball joint pinch bolt using power tool, then separate lower ball joint from steering

6. Remove drive shaft from wheel hub and bearing assembly,

using a puller or suitable tool.

CAUTION:

• When removing drive shaft, do not apply an excessive

angle to drive shaft joint. Also be careful not to exces-

sively extend slide joint.

7. Remove retaining bracket bolts using power tool, and pry drive

shaft from transaxle.

INSPECTION AFTER REMOVAL

• Move joint up/down, left/right, and in axial direction. Check for any rough movement or significant looseness.

• Check boot for cracks or other damage, and for grease leakage.

• If damaged, disassemble drive shaft to verify damage, and repair

or replace as necessary.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Do not reuse non-reusable parts.

1.

Cotter pin

2.

Drive shaft

3.

Retaining bracket

4.

Support bearing bracket

5.

Circlip

SDIA0972J

SFA989

WDIA0369E