Nissan Altima HL32 Hybrid. Instruction - part 388

EM-66

< ON-VEHICLE REPAIR >

[QR25DE]

CYLINDER HEAD

7. Install valve collet using Tool.

• Compress valve spring with valve spring compressor. Install valve collet with magnet hand.

• Tap stem edge lightly with plastic hammer after installation to check its installed condition.

8. Install valve lifter.

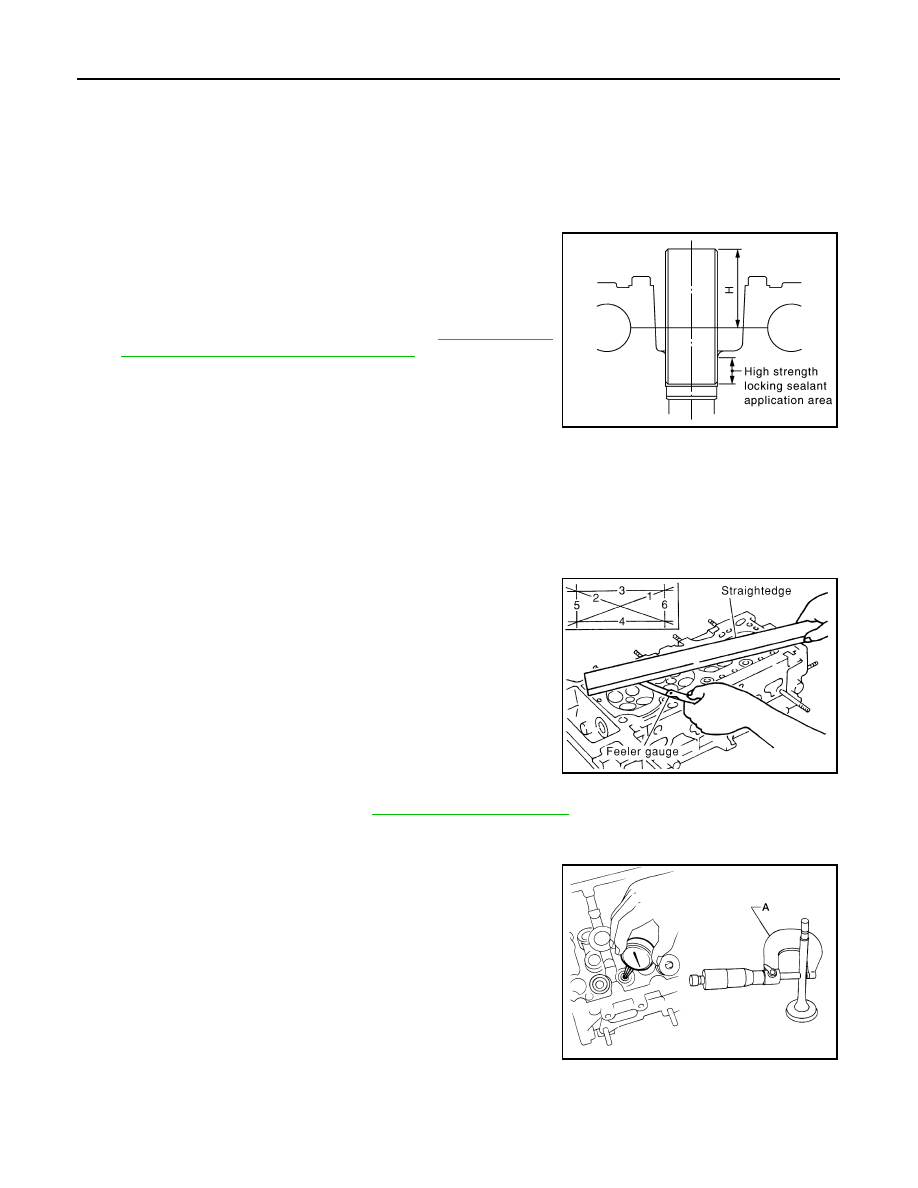

9. Install spark plug tube.

a. Remove old liquid gasket from cylinder head side mounting

hole.

b. Apply liquid gasket all around on spark plug tube with a 12 mm

(0.47 in) width from edge of spark plug tube on the press fit side.

• Use Three Bond or equivalent. Refer to

mended Chemical Products and Sealants"

c.

Press fit spark plug tube so that height is to (H) as shown.

CAUTION:

• When press fitting be careful not to deform spark plug tube.

• After press fitting, wipe off any protruding liquid gasket on top surface of cylinder head.

10. Install spark plug using suitable tool.

Inspection After Disassembly

INFOID:0000000004211258

CYLINDER HEAD DISTORTION

1. Wipe off oil and remove water scale deposits, old gasket, old

sealer, and carbon with a scraper.

CAUTION:

Use care not to allow gasket debris to enter passages for oil

or water.

2. At each of several locations on bottom surface of cylinder head,

measure distortion in six directions.

VALVE DIMENSIONS

Check dimensions of each valve. Refer to

.

VALVE GUIDE CLEARANCE

• Measure diameter of valve stem using suitable tool (A) as shown.

• Measure inner diameter of valve guide with a bore gauge as shown.

Tool number

: KV10116200 (J-26336-B)

: KV10115900 (J-26336-20)

Press fit height (H) standard value

: 41.7 mm (1.642 in)

PBIC2713E

Limit

: 0.1 mm (0.004 in)

PBIC0075E

Standard

Intake

: 5.965 - 5.980 mm (0.2348 - 0.2354 in)

Exhaust

: 5.955 - 5.970 mm (0.2344 - 0.2350 in)

AWBIA0068ZZ