Nissan Frontier. Instruction - part 704

PRECAUTIONS

EM-5

< PRECAUTION >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

Precaution for Assembly and Installation

INFOID:0000000009478032

• Use torque wrench to tighten bolts or nuts to specification.

• When tightening nuts and bolts, as a basic rule, equally tighten in several different steps starting with the

ones in center, then ones on inside and outside diagonally in this order. If the order of tightening is specified,

do exactly as specified.

• Replace with new gasket, packing, oil seal or O-ring.

• Thoroughly wash, clean, and air-blow each part. Carefully check engine oil or engine coolant passages for

any restriction and blockage.

• Avoid damaging sliding or mating surfaces. Completely remove foreign materials such as cloth lint or dust.

Before assembly, oil sliding surfaces well.

• Release air within route when refilling after draining engine coolant.

• Before starting engine, apply fuel pressure to fuel lines with turning ignition switch ON (with engine stopped).

Then make sure that there are no leaks at fuel line connections.

• After repairing, start engine and increase engine speed to check engine coolant, fuel, engine oil, and

exhaust gasses for leakage.

Parts Requiring Angle Tightening

INFOID:0000000009478033

• For the final tightening of the following engine parts use Tool:

- Cylinder head bolts

- Lower cylinder block bolts

- Connecting rod cap bolts

- Crankshaft pulley bolt (No angle wrench is required as bolt flange is provided with notches for angle tighten-

ing)

• Do not use a torque value for final tightening.

• The torque value for these parts are for a preliminary step.

• Ensure thread and seat surfaces are clean and coated with engine oil.

Precaution for Liquid Gasket

INFOID:0000000009478034

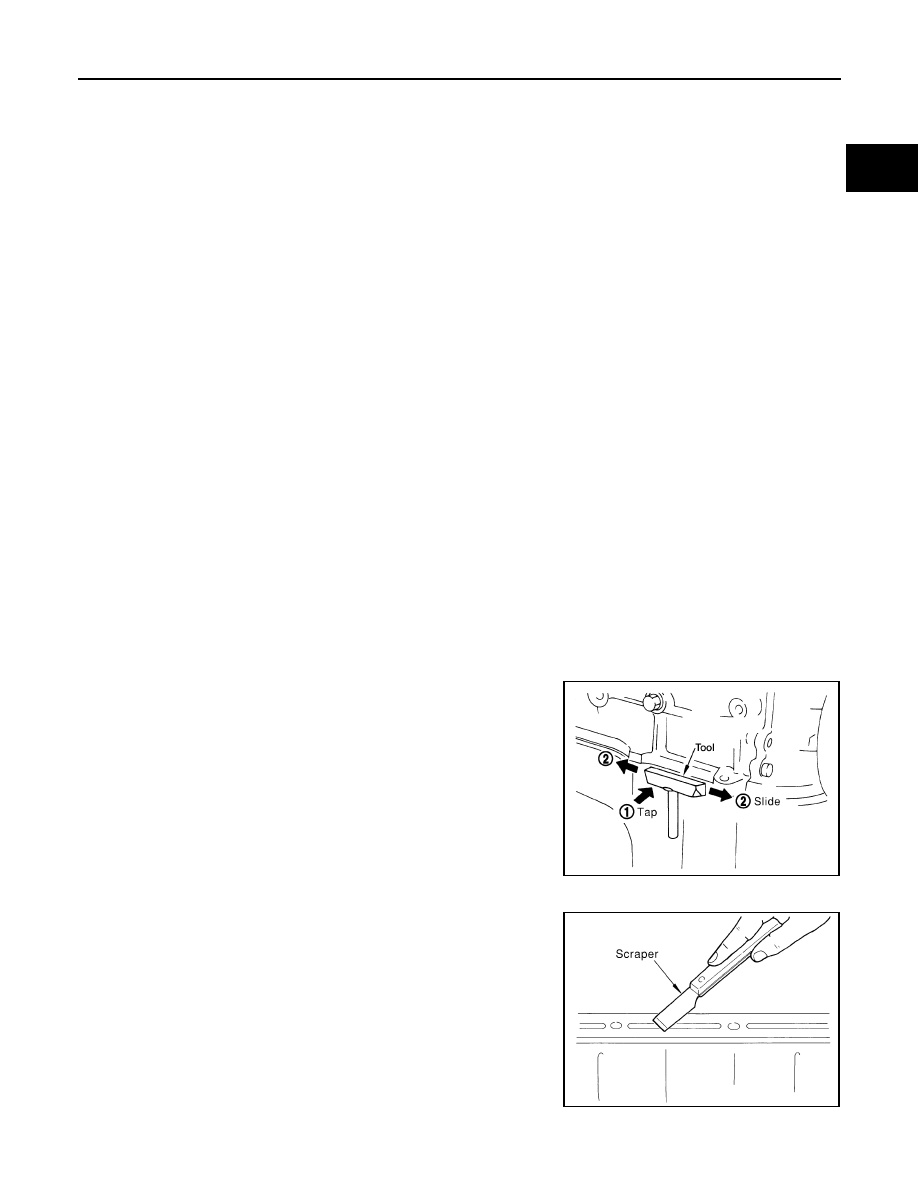

REMOVAL OF LIQUID GASKET

• After removing the bolts and nuts, separate the mating surface and

remove the old liquid gasket using Tool.

CAUTION:

Do not damage the mating surfaces.

• Tap the seal cutter to insert it (1).

• In areas where the Tool is difficult to use, lightly tap to slide it (2).

LIQUID GASKET APPLICATION PROCEDURE

1. Remove the old liquid gasket adhering to the gasket application

surface and the mating surface using suitable tool.

• Remove the liquid gasket completely from the groove of the

liquid gasket application surface, bolts, and bolt holes.

2. Thoroughly clean the mating surfaces and remove adhering

moisture, grease and foreign material.

Tool number

: KV10112100 (BT-8653-A)

Tool number

: KV10111100 (J-37228)

WBIA0566E

PBIC0003E