Nissan Pathfinder (2012 year). Instruction - part 291

FUEL PUMP

EC-409

< DTC/CIRCUIT DIAGNOSIS >

[VQ40DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

Component Inspection

INFOID:0000000007358374

FUEL PUMP

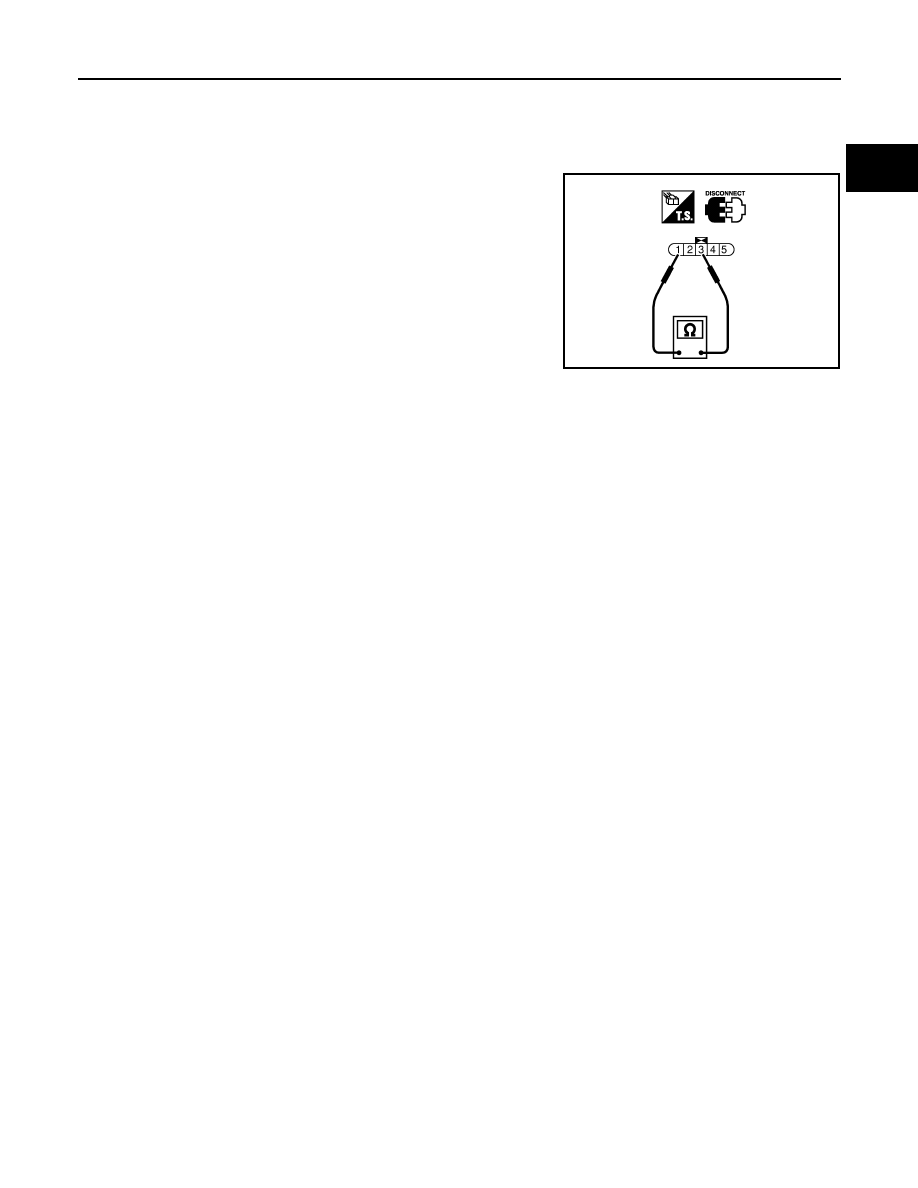

1. Disconnect “fuel level sensor unit and fuel pump” harness connector.

2. Check resistance between “fuel level sensor unit and fuel pump”

terminals 1 and 3.

Resistance: Approximately 0.2 - 5.0

Ω

[at 25

°

C (77

°

F)]

SEC918C

August 2012

2012 Pathfinder