Nissan Pathfinder (2011 year). Instruction - part 360

EC-934

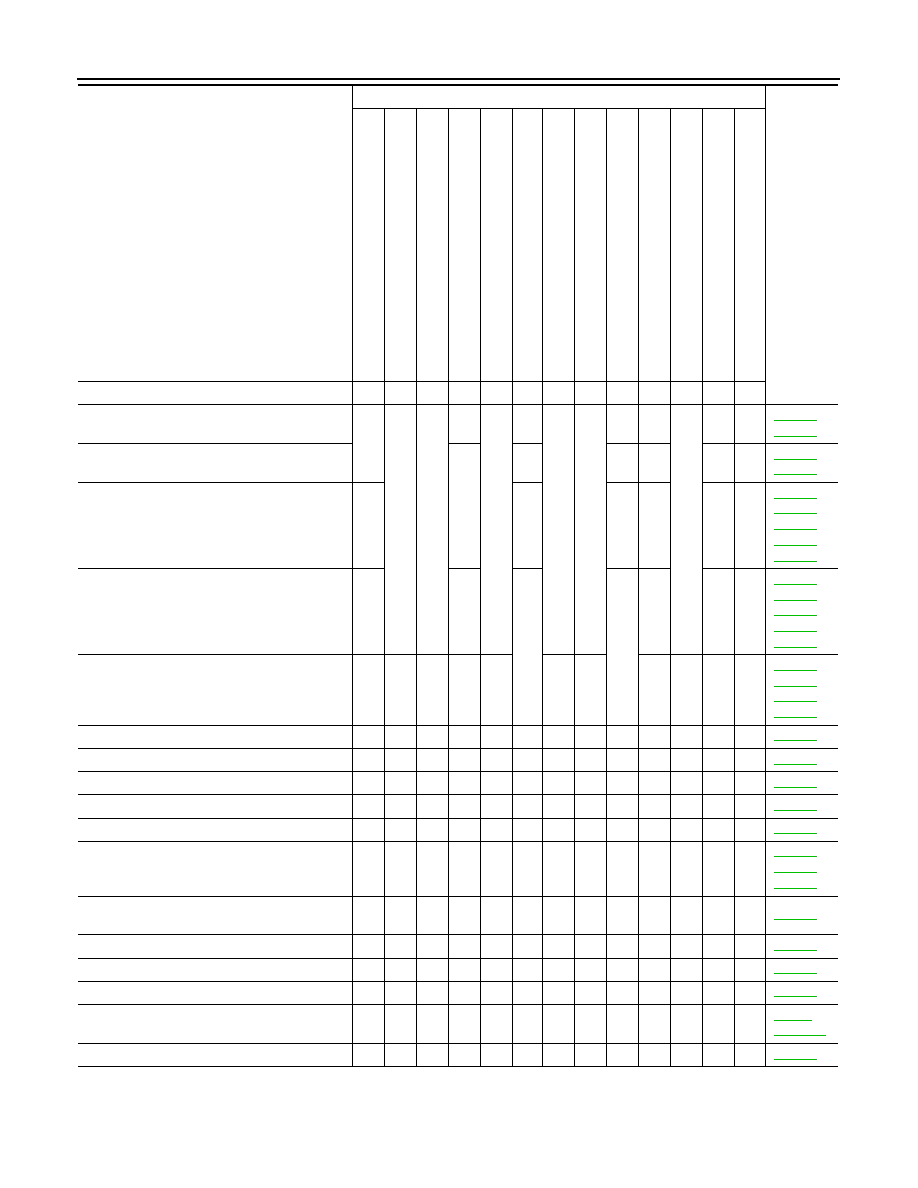

< SYMPTOM DIAGNOSIS >

[VK56DE]

ENGINE CONTROL SYSTEM SYMPTOMS

1 - 6: The numbers refer to the order of inspection.

(continued on next table)

SYSTEM — ENGINE MECHANICAL & OTHER

Mass air flow sensor circuit

1

1

2

2

2

2

2

2

Engine coolant temperature sensor circuit

3

3

3

Air fuel ratio (A/F) sensor 1 circuit

EC-665

EC-669

EC-673

EC-677

EC-897

Throttle position sensor circuit

2

2

EC-653

EC-718

EC-837

EC-839

EC-889

Accelerator pedal position sensor circuit

3

2

1

Knock sensor circuit

2

3

Crankshaft position sensor (POS) circuit

2

2

Camshaft position sensor (PHASE) circuit

3

2

Vehicle speed signal circuit

2

3

3

3

Power steering pressure sensor circuit

2

3

3

ECM

2

2

3

3

3

3

3

3

3

3

3

Intake valve timing control solenoid valve cir-

cuit

3

2

1

3

2

2

3

3

Park/neutral position (PNP) signal circuit

3

3

3

3

3

Refrigerant pressure sensor circuit

2

3

3

4

Electrical load signal circuit

3

Air conditioner circuit

2

2

3

3

3

3

3

3

3

3

2

or

ABS actuator and electric unit (control unit)

4

SYMPTOM

Refer-

ence page

HARD/NO S

TA

R

T/RES

TA

R

T (E

XCP

. HA)

E

N

GINE

ST

ALL

HES

IT

A

TION/SURGING/FLA

T

SPOT

S

P

ARK KNOC

K

/DET

O

NA

TI

ON

LACK OF

POWER/POOR ACCELERA

TION

HIG

H

IDL

E

/L

OW

ID

LE

ROUGH IDLE/HUNTING

ID

LING VI

BRA

T

ION

S

LOW/NO RETU

RN

T

O ID

LE

OVERHEA

T

S

/W

A

TER TEMPERA

T

URE HIG

H

E

XCESSIVE

FUEL CON

S

UMP

T

ION

E

XCESSIVE

OIL

C

O

NSUMP

T

ION

B

A

TTER

Y

DEAD (UNDER CHARGE)

Warranty symptom code

AA

AB

AC

AD

AE

AF AG AH

AJ

AK

AL

AM HA

2011 Pathfinder