Nissan Pathfinder (2011 year). Instruction - part 227

DLN-354

< REMOVAL AND INSTALLATION >

[FRONT FINAL DRIVE: R180A]

SIDE OIL SEAL

SIDE OIL SEAL

Removal and Installation

INFOID:0000000006245180

REMOVAL

1. Remove the drive shafts from the front final drive assembly. Refer to

.

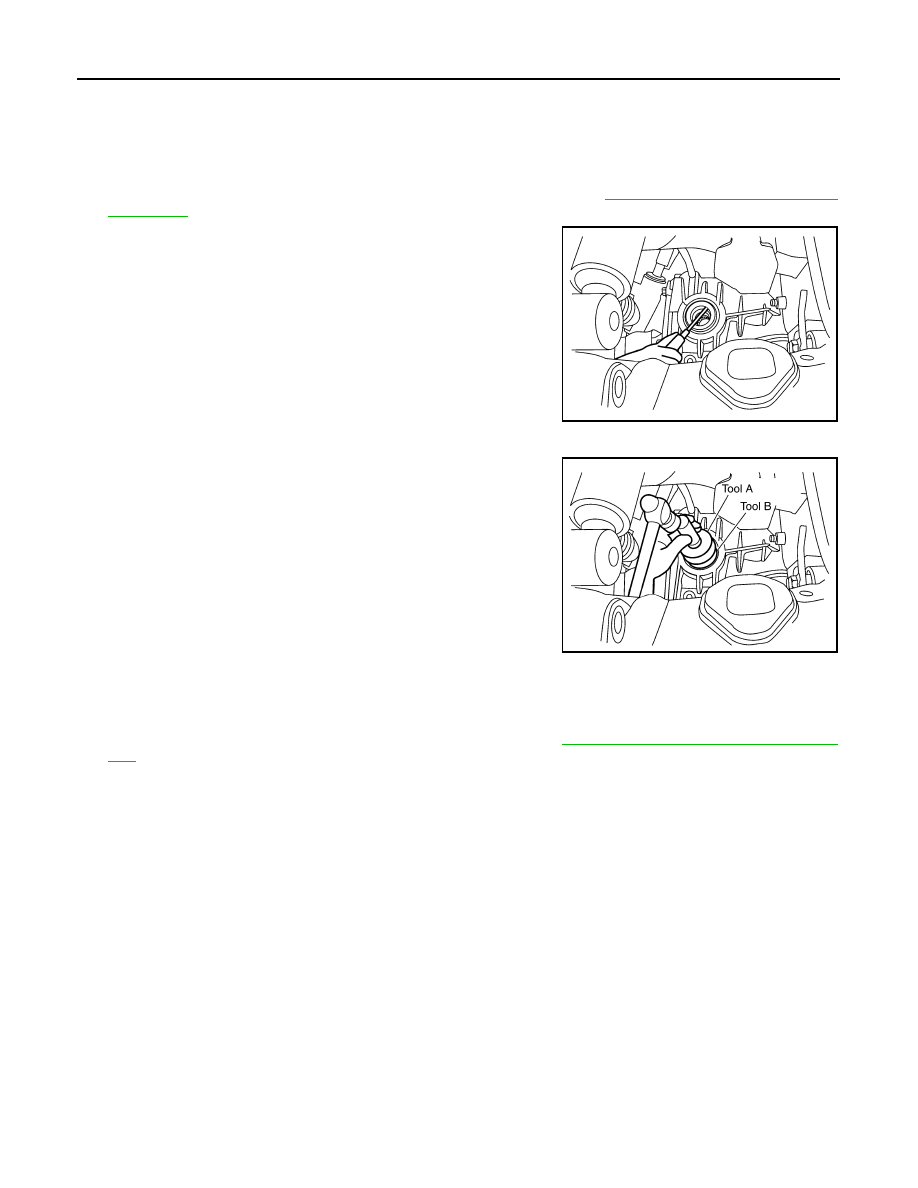

2. Remove the side oil seal using suitable tool.

CAUTION:

Do not reuse the side oil seal.

INSTALLATION

1. Apply multi-purpose grease to the lips and differential gear oil to

the circumference of the new side oil seal. Then drive the new

side oil seal in evenly until it becomes flush with the gear carrier

using Tools.

CAUTION:

• Do not reuse side oil seal.

• Do not incline the new side oil seal when installing.

• Apply multi-purpose grease to the lips and differential

gear oil to the circumference of the new side oil seal.

2. Installation of the remaining components is in the reverse order of removal.

CAUTION:

Check the differential gear oil level after installation. Refer to

DLN-351, "Checking Differential Gear

.

LDIA0173E

Tool number

A: ST30720000 (J-25405)

B: ST27863000 ( — )

PDIA0826E

2011 Pathfinder