Nissan Pathfinder (2011 year). Instruction - part 133

PRECAUTIONS

CO-35

< PRECAUTION >

[VK56DE]

C

D

E

F

G

H

I

J

K

L

M

A

CO

N

P

O

5. When the repair work is completed, return the ignition switch to the

″

LOCK

″

position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-III.

Precaution for Liquid Gasket

INFOID:0000000006247867

REMOVAL OF LIQUID GASKET SEALING

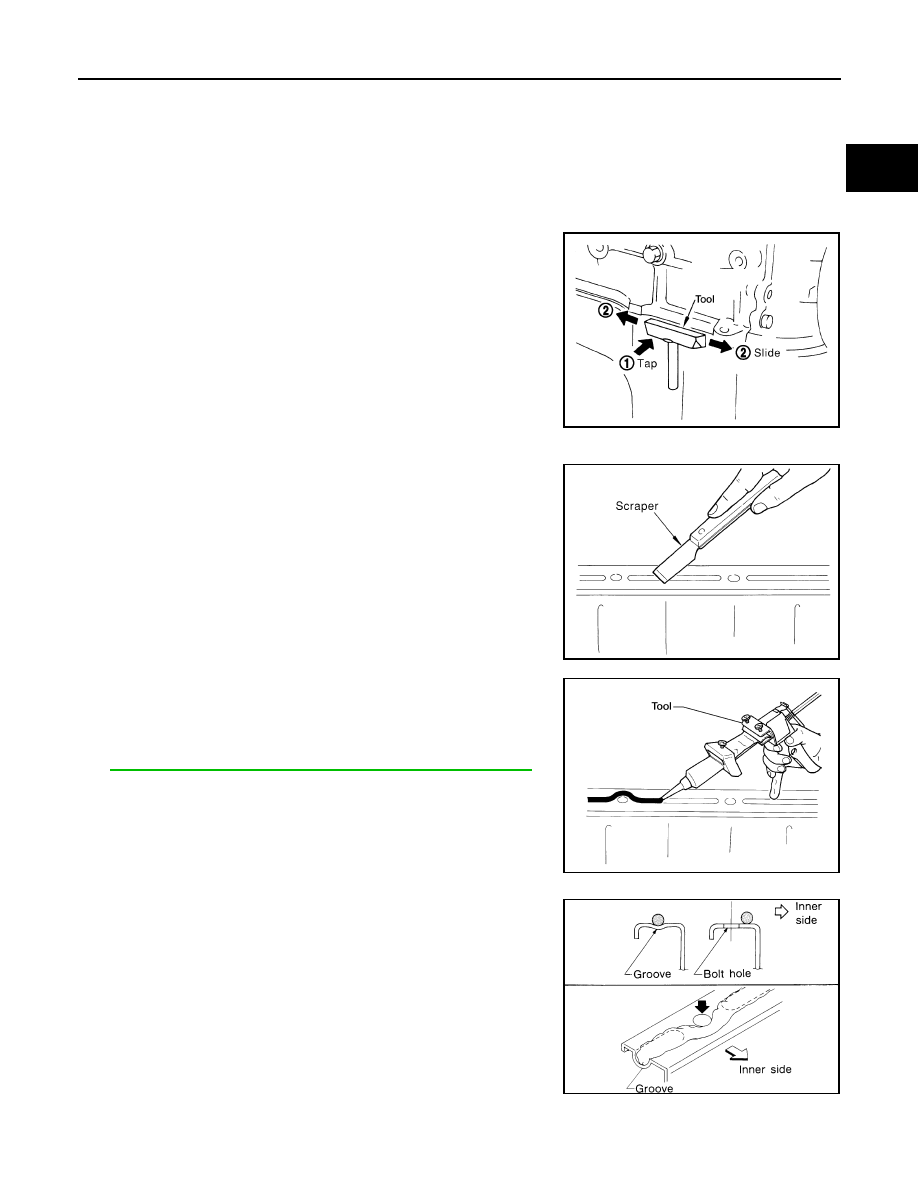

• After removing nuts and bolts, separate the mating surface, using Tool and remove old liquid gasket sealing.

CAUTION:

Be careful not to damage the mating surfaces.

• Tap (1) Tool to insert it, and then slide (2) it by tapping on the side

as shown.

• In areas where Tool is difficult to use, use plastic hammer to lightly

tap the part, to remove it.

CAUTION:

If for some unavoidable reason suitable tool such as screw-

driver is used, be careful not to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

1. Remove the old liquid gasket adhering to the gasket application

surface and the mating surface using suitable tool.

• Remove the liquid gasket completely from the groove of the

liquid gasket application surface, bolts, and bolt holes.

2. Thoroughly clean the mating surfaces and remove adhering

moisture, grease and foreign material.

3. Attach the liquid gasket tube to the Tool.

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-14, "Recommended Chemical Products and Sealants"

.

4. Apply the liquid gasket without breaks to the specified location

with the specified dimensions.

• If there is a groove for the liquid gasket application, apply the

liquid gasket to the groove.

• As for the bolt holes, normally apply the liquid gasket inside

the holes. If specified in the procedure, it should also be

applied outside the holes.

• Within five minutes of liquid gasket application, install the mat-

ing component.

• If the liquid gasket protrudes, wipe it off immediately.

• Do not retighten after the installation.

• Wait 30 minutes or more after installation before refilling the

engine with engine oil and engine coolant.

CAUTION:

If there are specific instructions in this instruction, observe them.

Tool number

: KV10111100 (J-37228)

WBIA0566E

PBIC0003E

Tool number

: WS39930000 ( — )

WBIA0567E

SEM159F

2011 Pathfinder