Nissan Pathfinder (2006 year). Instruction - part 308

HEADLAMP (FOR USA)

LT-19

C

D

E

F

G

H

I

J

L

M

A

B

LT

2006 Pathfinder

5.

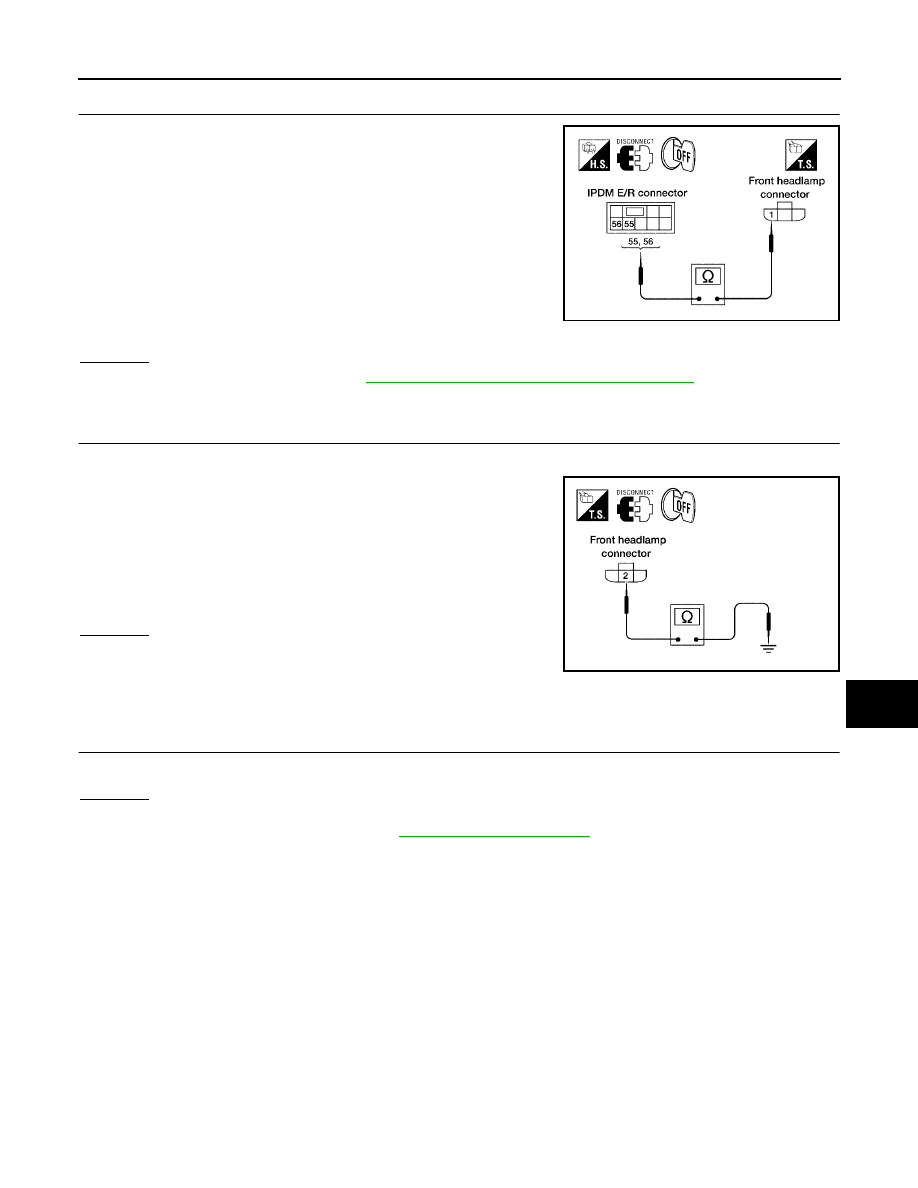

CHECK HEADLAMP CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect IPDM E/R connector.

3.

Check continuity between IPDM E/R harness connector E123

terminal 56 and front headlamp RH harness connector E107 ter-

minal 1.

4.

Check continuity between IPDM E/R harness connector E123

terminal 55 and front headlamp LH harness connector E11 ter-

minal 1.

OK or NG

OK

>> Replace IPDM E/R. Refer to

PG-32, "Removal and Installation of IPDM E/R"

NG

>> Repair harness or connector.

6.

CHECK HEADLAMP GROUND

1.

Turn ignition switch OFF.

2.

Check continuity between front headlamp RH harness connec-

tor E107 terminal 2 and ground.

3.

Check continuity between front headlamp LH harness connector

E11 terminal 2 and ground.

OK or NG

OK

>> Check front headlamp connector for damage or poor

connection. Repair as necessary.

NG

>> Repair harness or connector.

Headlamp HI Does Not Illuminate (One Side)

EKS00FUB

1.

BULB INSPECTION

Inspect inoperative headlamp bulb.

OK or NG

OK

>> GO TO 2.

NG

>> Replace headlamp bulb. Refer to

56 - 1

: Continuity should exist.

55 - 1

: Continuity should exist.

WKIA3498E

2 - Ground

: Continuity should exist.

2 - Ground

: Continuity should exist.

WKIA3499E