Nissan Pathfinder. Instruction - part 674

PRECAUTIONS

HA-7

< PRECAUTION >

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

• Read and follow all manufacturer’s operating instructions and precautions prior to performing the

work for the purpose of safety and customer’s satisfaction.

• A compressor shaft seal should not necessarily be repaired because of dye seepage. The compres-

sor shaft seal should only be repaired after confirming the leakage with an electronic leak detector

(SST: J-41995).

• Always remove any remaining dye from the leakage area after repairs are completed to avoid a mis-

diagnosis during a future service.

• Do not allow dye to come into contact with painted body panels or interior components. Clean imme-

diately with the approved dye cleaner if dye is spilled. Fluorescent dye left on a surface for an

extended period of time cannot be removed.

• Do not spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

• Do not use more than one refrigerant dye bottle [1/4 ounce (7.4 cc)] per A/C system.

• Leak detection dyes for HFC-134a (R-134a) and CFC-12 (R-12) A/C systems are different. Do not use

HFC-134a (R-134a) leak detection dye in CFC-12 (R-12) A/C system or CFC-12 (R-12) leak detection

dye in HFC-134a (R-134a) A/C system or A/C system damage may result.

• The fluorescent properties of the dye remains for three or more years unless a compressor malfunc-

tion occurs.

NOTE:

Identification

• Vehicles with factory installed fluorescent dye have a green label.

• Vehicles without factory installed fluorescent dye have a blue label.

Service Equipment

INFOID:0000000009723959

RECOVERY/RECYCLING RECHARGING EQUIPMENT

Be certain to follow the manufacturer’s instructions for machine operation and machine maintenance. Do not

introduce any refrigerant other than that specified into the machine.

ELECTRONIC LEAK DETECTOR

Be certain to follow the manufacturer’s instructions for detector operation and maintenance.

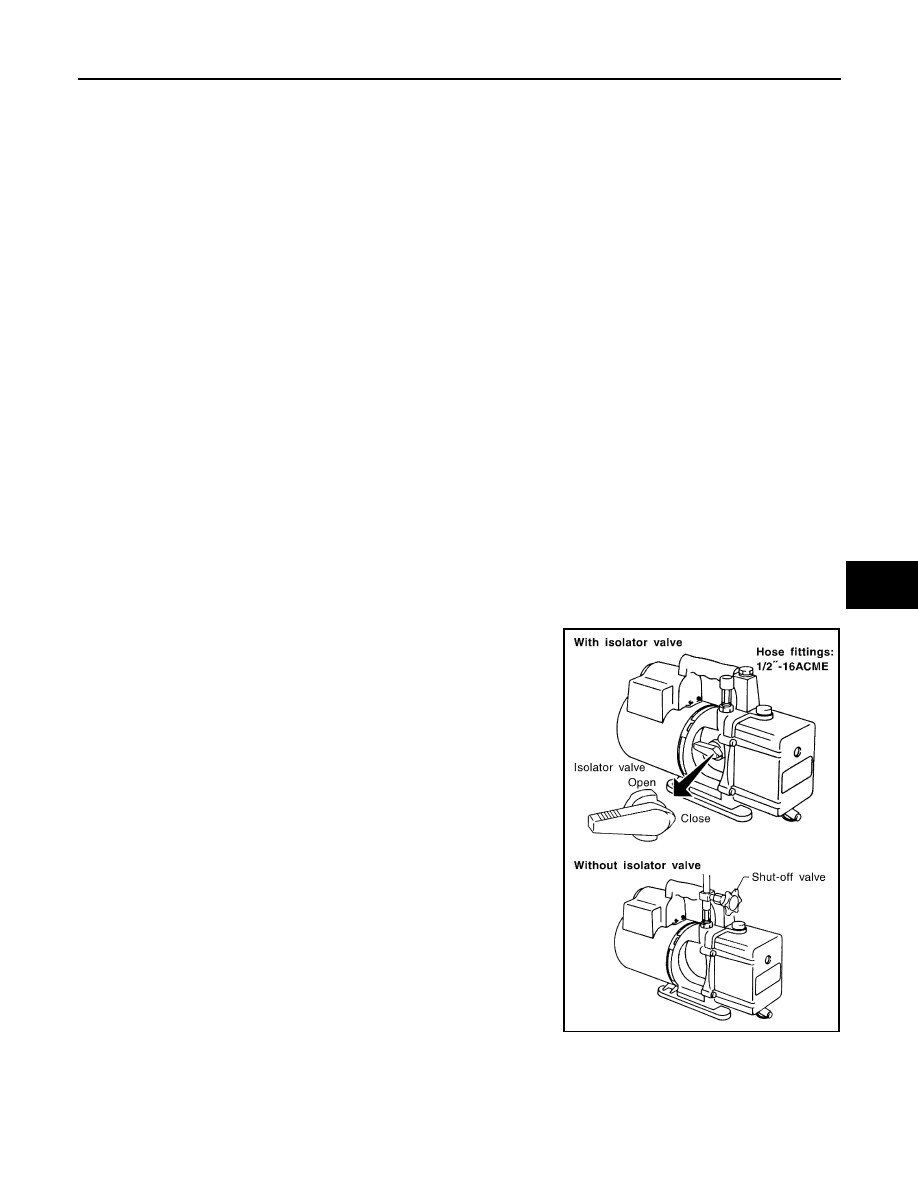

VACUUM PUMP

The oil contained inside the vacuum pump is not compatible with the

specified oil for HFC-134a (R-134a) A/C systems. The vent side of

the vacuum pump is exposed to atmospheric pressure, so the vac-

uum pump oil may migrate out of the pump into the service hose.

This is possible when the pump is switched OFF after evacuation

(vacuuming) and hose is connected to it.

To prevent this migration, use a instruction valve placed near the hose-

to-pump connection, as per the following.

• Vacuum pumps usually have a instruction isolator valve as part of the

pump. Close this valve to isolate the service hose from the pump.

• Use a hose equipped with a instruction shut-off valve near the pump

end for pumps without an isolator. Close the valve to isolate the

hose from the pump.

• Disconnect the hose from the pump if the hose has an automatic

shut-off valve. As long as the hose is connected, the valve is open

and oil may migrate.

Some one-way valves open when vacuum is applied and close

under no vacuum condition. Such valves may restrict the pump’s

ability to pull a deep vacuum and are not recommended.

MANIFOLD GAUGE SET

RHA270DA