Nissan Pathfinder. Instruction - part 572

CYLINDER BLOCK

EM-127

< UNIT DISASSEMBLY AND ASSEMBLY >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

6. Install main bearing caps, and tighten to the specified torque. Otherwise, cylinder bores may be distorted

after boring.

7. Cut cylinder bores.

• When any cylinder needs boring, all other cylinders must also be bored.

• Do not cut too much out of cylinder bore at a time. Cut only 0.05 mm (0.0020 in) or so in diameter

at a time.

8. Hone cylinders to obtain specified piston-to-bore clearance.

9. Measure finished cylinder bore for out-of-round and taper.

• Measurement should be done after cylinder bore cools down.

CRANKSHAFT

1. Check the crankshaft main and pin journals for scoring, wear, or

cracks.

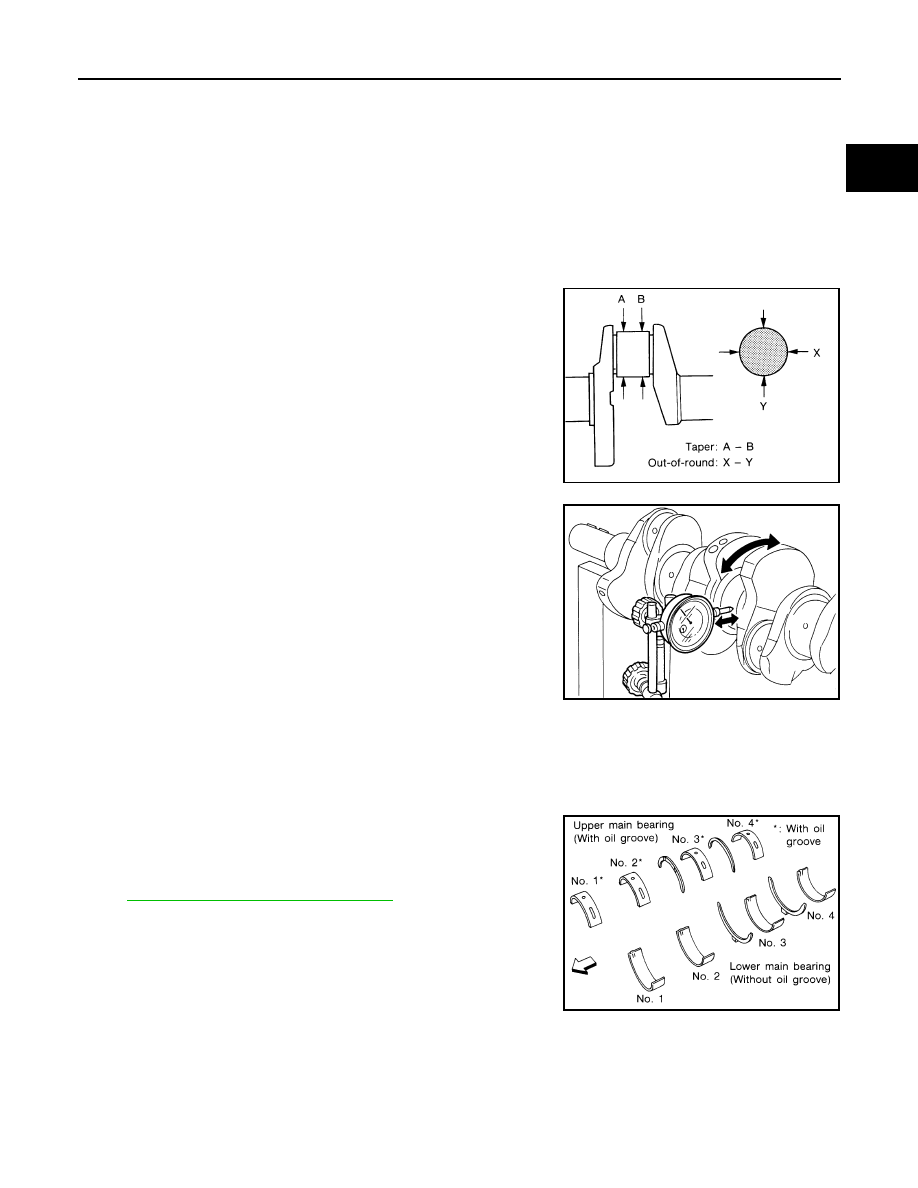

2. Measure the journals for taper and out-of-round.

3. Measure crankshaft runout.

a. Place a V-block on a precise flat table to support the journals on

the both ends of the crankshaft.

b. Place a dial gauge straight up on the No. 3 journal.

c. While rotating the crankshaft, read the movement of the pointer

on the dial gauge.

BEARING CLEARANCE

• Use either of the following two methods, however method (A) gives more reliable results and so is the pre-

ferred method.

Method A (Using Bore Gauge and Micrometer)

Main Bearing

1. Set the main bearings in their proper positions on the cylinder

block and the main bearing cap.

2. Install the main bearing caps and bearing beam to the cylinder

block. Tighten all bolts in the numerical order as specified. Refer

EM-112, "Disassembly and Assembly"

.

Standard

Out-of-round (X - Y) : 0.002 mm (0.0001 in)

Taper (A - B)

: 0.002 mm (0.0001 in)

SEM316A

Runout limit (total indicator

reading)

: 0.10 mm (0.0039 in)

SEM346D

SEM175F