Nissan Juke F15. Instruction - part 422

P1807, P1808 BRAKE PEDAL POSITION SWITCH

EC-501

< DTC/CIRCUIT DIAGNOSIS >

[MR FOR NISMO RS MODELS]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

P1807, P1808 BRAKE PEDAL POSITION SWITCH

DTC Logic

INFOID:0000000013475492

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure

before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE 1

With CONSULT

1. Turn ignition switch ON.

2. Select “BRAKE SW1” in “DATA MONITOR” mode of “ENGINE” using CONSULT.

3. Check “BRAKE SW1” indication as per the following conditions.

Without CONSULT

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector terminals as per the following.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Proceed to

.

3.

PERFORM DTC CONFIRMATION PROCEDURE 2

1. Turn ignition switch ON.

2. Depress the brake pedal for at least 100 times.

3. Check DTC.

Is DTC detected?

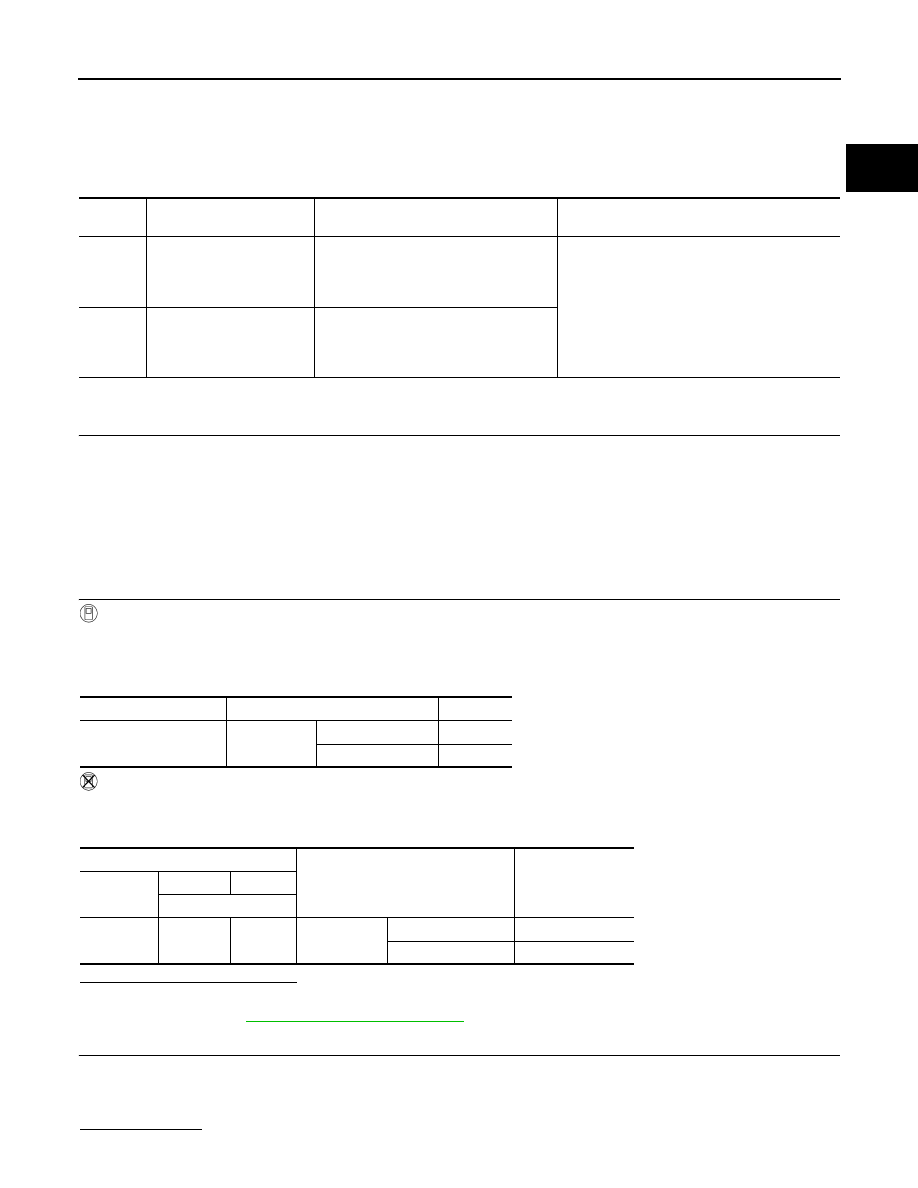

DTC No.

Trouble diagnosis name

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P1807

Brake pedal position switch

(Brake pedal position

switch)

Regardless of ON/OFF of stop lamp

switch signal when brake pedal is de-

pressed 100 times, a brake pedal posi-

tion switch signal remains OFF.

• Harness or connectors

(Brake pedal position switch circuit is shorted.)

• Brake pedal position switch

• Incorrect brake pedal position switch installa-

tion

• ECM

P1808

Brake pedal position switch

(Brake pedal position

switch)

Regardless of ON/OFF of stop lamp

switch signal when brake pedal is de-

pressed 100 times, a brake pedal posi-

tion switch signal remains ON.

Monitor item

Condition

Indication

BRAKE SW1

Brake pedal

Slightly depressed

OFF

Fully released

ON

ECM

Condition

Voltage

(Approx.)

Connector

+

–

Terminal

E18

116

127

Brake pedal

Slightly depressed

0 V

Fully released

Battery voltage