Lexus GS300/400 (2000 year). Service manual - part 210

B09507

B01620

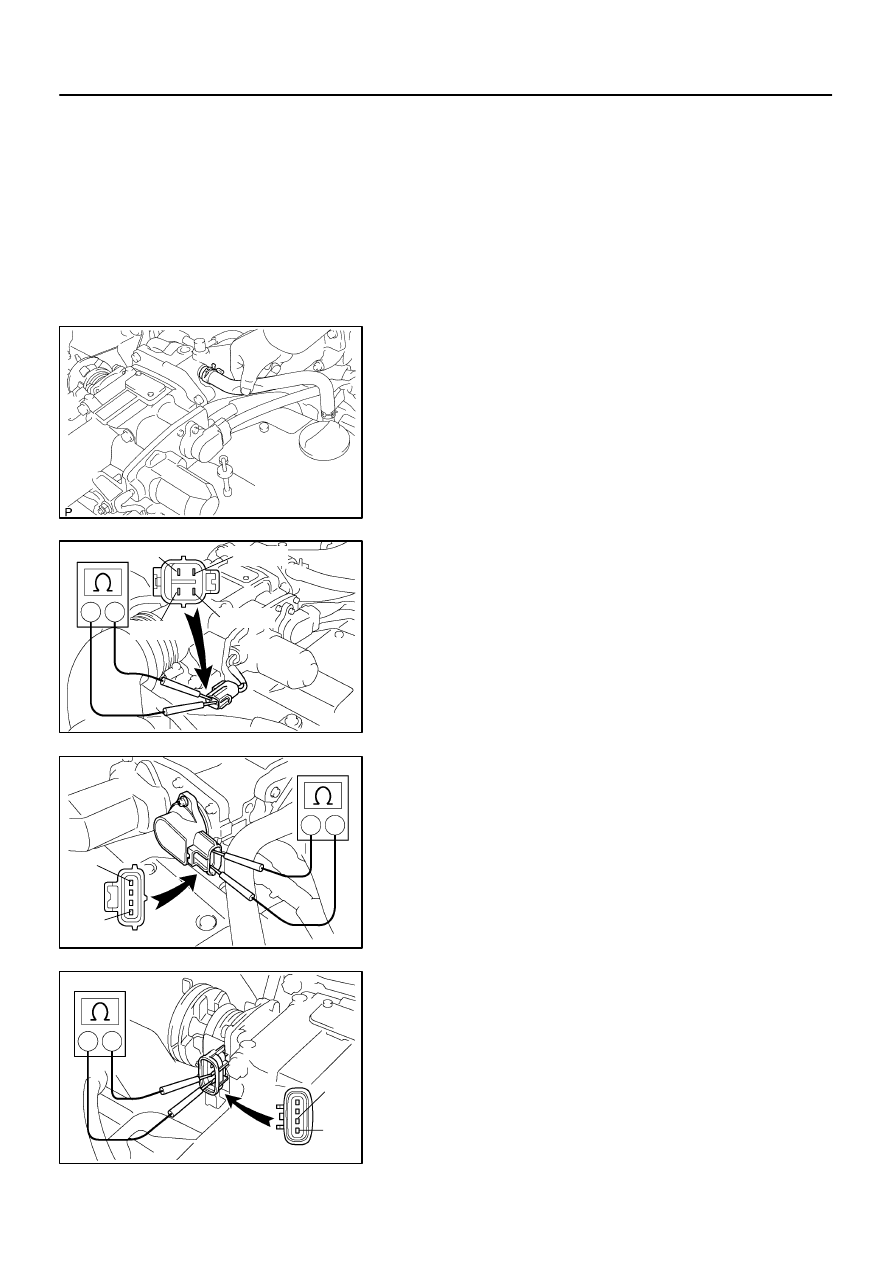

Ohmmeter 3 (CL–)

4 (CL+)

1 (M+)

2 (M–)

B01942

VC

Ohmmeter

E2

B01943

VC

Ohmmeter

E2

–

SFI (2JZ–GE)

THROTTLE BODY

SF–33

1499

(2)

Turn the A/C switch ON and OFF, and check the idle

speed.

Idle speed (Transmission in neutral):

700

±

50 rpm (A/C OFF)

750

±

50 rpm (A/C ON)

NOTICE:

Perform inspection under condition without electrical load.

(3)

With engine idling, pinch the air assist hose and

check that engine speed drops, and then returns

back up to idle speed.

If operation is not as specified, check the throttle body, wiring

and ECM.

(f)

After checking the above (b) to (e), perform the diving test

and check that there is no sense of incongruity.

3.

INSPECT THROTTLE CONTROL MOTOR

(a)

Disconnect the throttle control motor connector.

(b)

Using an ohmmeter, measure the resistance between ter-

minal 3 (CL–) and 4 (CL+).

Resistance: 4.2 – 5.2

Ω

at 20

°

C (68

°

F)

(c)

Using an ohmmeter, measure the resistance between ter-

minal 1 (M+) and 2 (M–).

Resistance: 0.3 – 100

Ω

at 20

°

C (68

°

F)

If the resistance is not as specified, replace the throttle control

motor. (See page

)

(d)

Reconnect the throttle control motor connector.

4.

INSPECT THROTTLE POSITION SENSOR

(a)

Disconnect the throttle position sensor connector.

(b)

Using an ohmmeter, measure the resistance between ter-

minals VC and E2.

Resistance: 1.2 – 3.2 k

Ω

at 20

°

C (68

°

F)

If the resistance is not as specified, replace the throttle position

sensor. (See page

)

(c)

Reconnect the throttle position sensor connector.

5.

INSPECT ACCELERATOR PEDAL POSITION SEN-

SOR

(a)

Disconnect the accelerator pedal position sensor con-

nector.

(b)

Using an ohmmeter, measure the resistance between ter-

minals VC and E2.

Resistance: 1.2 – 3.2 k

Ω

at 20

°

C (68

°

F)

If the resistance is not as specified, replace the accelerator ped-

al position sensor. (See page