Lexus GS300/400 (2000 year). Service manual - part 203

–

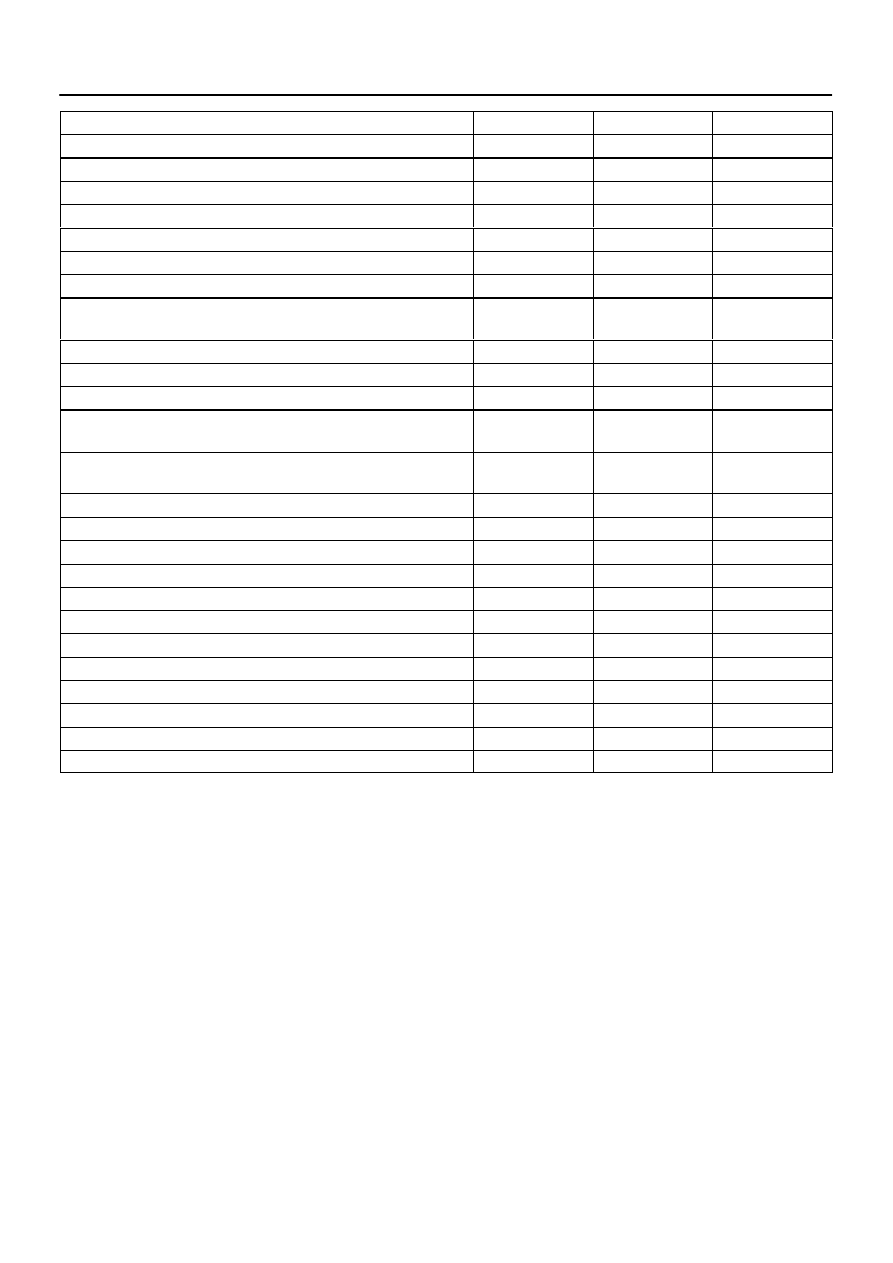

SERVICE SPECIFICATIONS

ENGINE MECHANICAL (2JZ–GE)

SS–9

165

Part tightened

N·m

kgf·cm

ft·lbf

Drive plate x Torque converter clutch

48

490

35

Rear support member x Engine rear mounting insulator

13.5

135

10

Front suspension crossmember x Engine mounting insulator

70

714

52

PS gear housing x Front suspension member

65

660

48

Sliding yoke x Steering intermediate shaft

35

360

26

Transmission control rod x Shift lever

13

130

9

Transmission control rod x Transmission

13

130

9

A/C compressor x Cylinder block

Stud bolt

Bolt and nut

26

52

265

530

19

38

Fuel inlet hose x Fuel pipe support

29

300

22

Front suspension member brace x Front suspension member

58

590

43

Front suspension member brace x Strut bar bracket plate

58

590

43

Connecting rod cap x Connecting rod

1st

2nd

30

Turn 90

°

300

Turn 90

°

22

Turn 90

°

Main bearing cap x Cylinder block

1st

2nd

45

Turn 90

°

450

Turn 90

°

33

Turn 90

°

Rear oil seal retainer x Cylinder block

6.0

60

53

Engine mounting bracket x Cylinder block

59

590

44

Fuel inlet pipe x Cylinder block

29

290

21

No.1 oil pipe x Cylinder block

55

550

41

Oil filter bracket x Cylinder block

90

900

66

No.2 water bypass pipe x Water pump

21

210

15

No.2 water bypass pipe x Cylinder block

21

210

15

Generator x Water pump

40

400

30

Generator x Cylinder block

40

400

30

Front exhaust pipe x Center exhaust pipe

44

440

32

Center exhaust pipe x Tailpipe

44

440

32

Heated oxygen sensor x Front exhaust pipe

45

450

33