Lexus GS300/400 (2000 year). Service manual - part 97

I04105

Dark

(10k

Ω

)

Bright

(0

Ω

)

4

5

I01322

Battery

Ignition

Switch

Warning Light

2

1

Wire Harness Side

I01323

1

2

OFF

ON

I01328

Battery

Ignition

Switch

Warning Light

2

1

Wire Harness Side

I04107

1

2

4

OFF

ON

BE–102

–

BODY ELECTRICAL

COMBINATION METER

2403

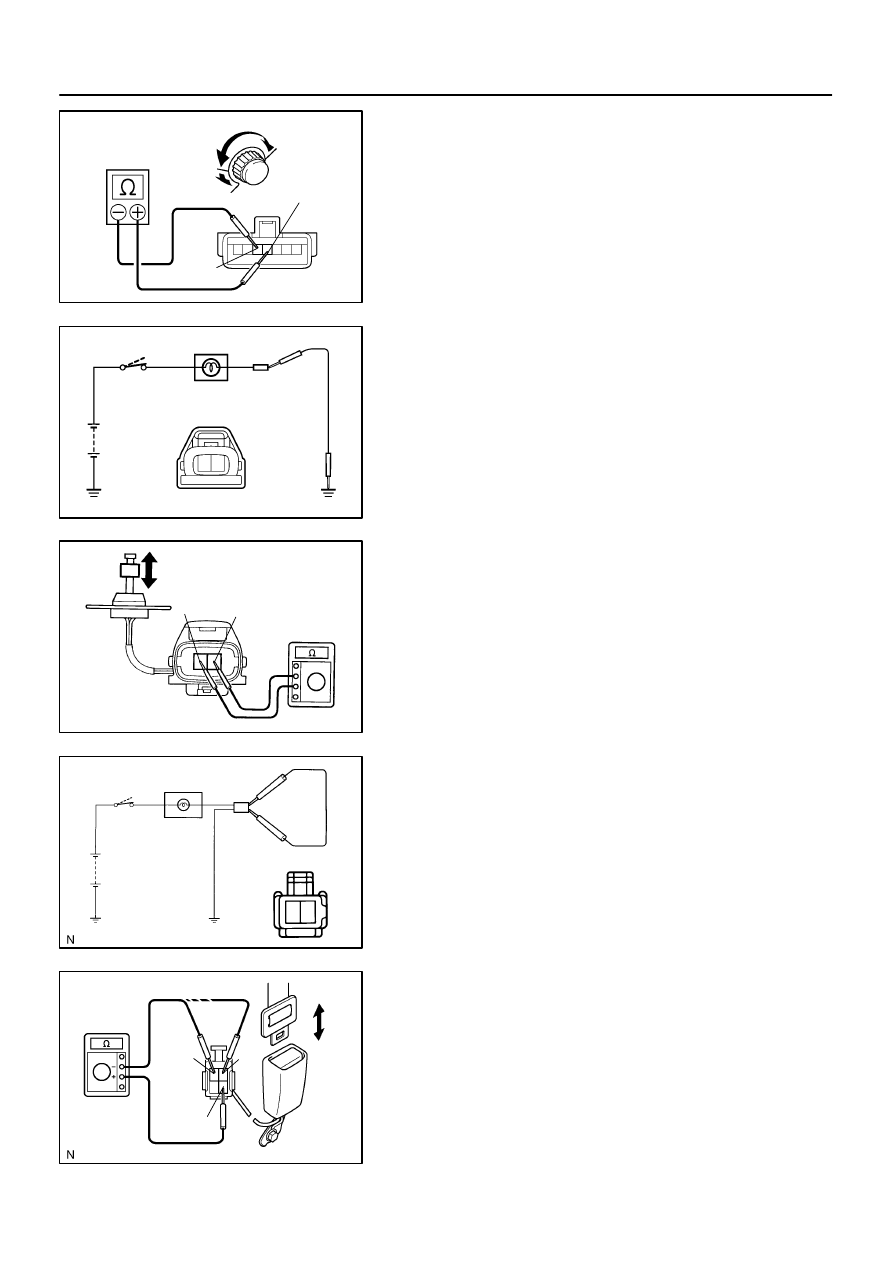

30.

INSPECT LIGHT CONTROL RHEOSTAT OPERATION

Gradually, turn the rheostat knob from the bright side to dark

side and check that the resistance decreases from 10 k

Ω

to 0

Ω

between terminal 4 and 5. (Rheostat knob turned to clock-

wise)

If operation is not as specified, replace the rheostat light control.

31.

INSPECT WINDOW WASHER LEVEL WARNING

LIGHT

(a)

Disconnect the connector from the warning switch and

ground terminal on the wire harness side connector.

(b)

Engine running and check that the warning light lights up.

If the warning light does not light up, inspect the bulb or wire har-

ness.

32.

INSPECT WINDOW WASHER LEVEL WARNING

SWITCH CONTINUITY

(a)

Check that no continuity exists between the terminals with

the switch OFF (float up).

(b)

Check that continuity exists between the terminals with

the switch ON (float down).

If operation is not as specified, replace the switch or inspect

ground point.

33.

INSPECT SEAT BELT WARNING LIGHT

(a)

Disconnect the connector from the retractor switch and

ground terminal on the wire harness side connector.

(b)

Turn the ignition switch ON and check that the warning

light lights up.

If the warning light does not light up, inspect the bulb or wire har-

ness.

34.

INSPECT SEAT BELT BUCKLE SWITCH CONTINUITY

(a)

Check that continuity exists between the terminals 1 and

4 on the switch side connector with the switch ON (belt

fastened).

(b)

Check that continuity exists between the terminals 2 and

4 on the switch side connector with the switch OFF (belt

unfastened).

If operation is not as specified, replace the switch.